Sewing machine for long-striped ribbon

A technology for ribbons and sewing machines, applied to sewing machine components, sewing equipment, cloth feeding mechanisms, etc., can solve problems such as reduced productivity, poor sewing efficiency, and easily damaged fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, embodiments of the present invention will be described based on the drawings.

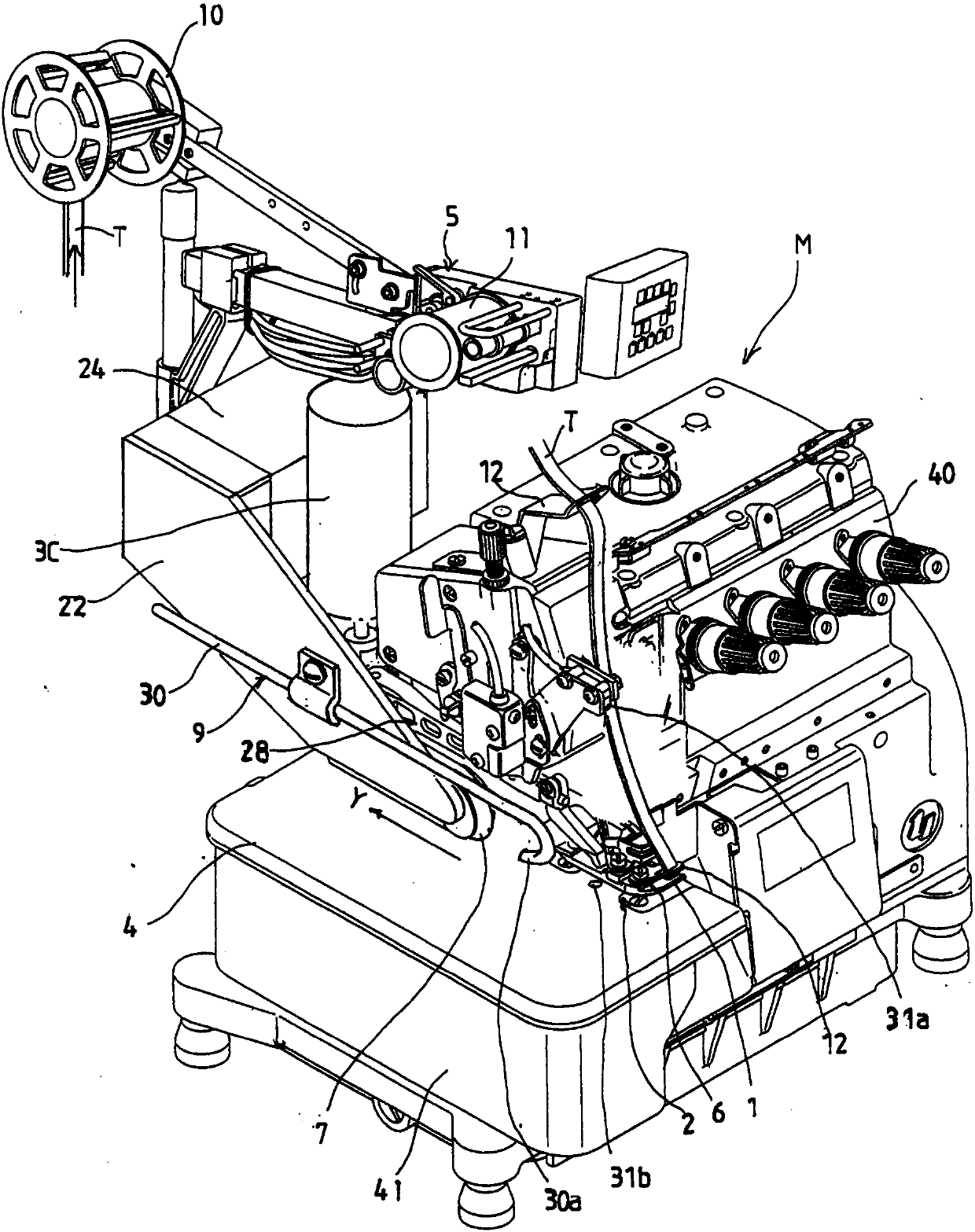

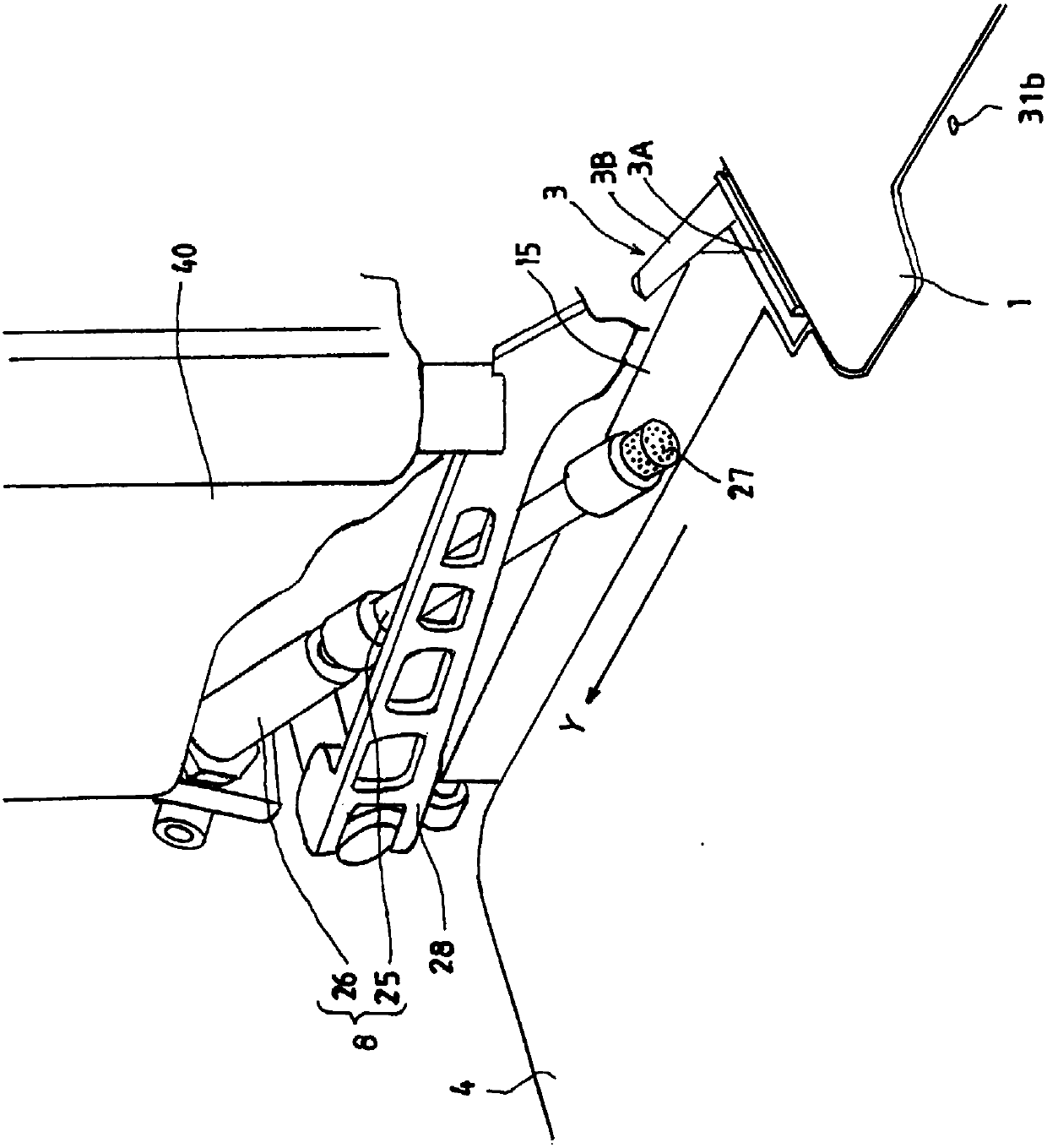

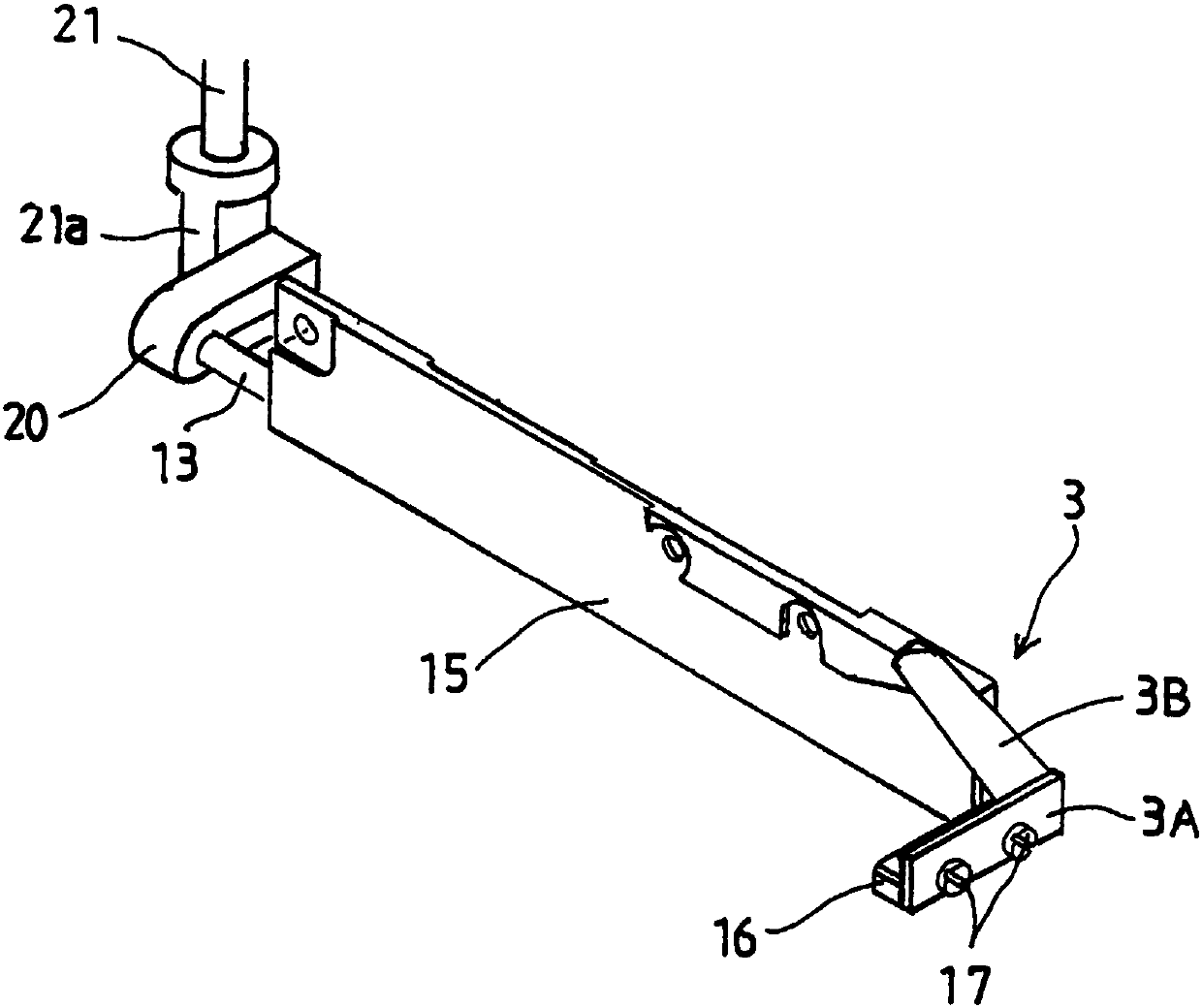

[0057] figure 1 It is an overall perspective view of a sewing machine for sewing long strips according to the present invention, figure 2 It is an enlarged perspective view of the main part of the sewing machine for sewing long ribbons.

[0058] In the above-mentioned sewing machine M for sewing long strips, the upper part of the sewing machine base part 41 connected to the left side part of the sewing machine frame 40 is provided with a Figure 7 The shown special shape cuts the material W and the needle plate 1 and the material slide plate (cross plate) 4 that guide the conveyance of the cut material W to the sewing travel direction Y, and the above-mentioned The feed dog and its drive mechanism for intermittently feeding the cut material W toward the sewing travel direction Y are well known, and therefore illustrations and descriptions of specific structures are omitted. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com