Self-locking type flow control valve

A flow control valve, self-locking technology, applied in the direction of lift valve, safety valve, balance valve, etc., can solve the problems of environmental pollution, waste of pipe network resources, high cost, etc., to reduce environmental pollution, reduce labor intensity, and easy to manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

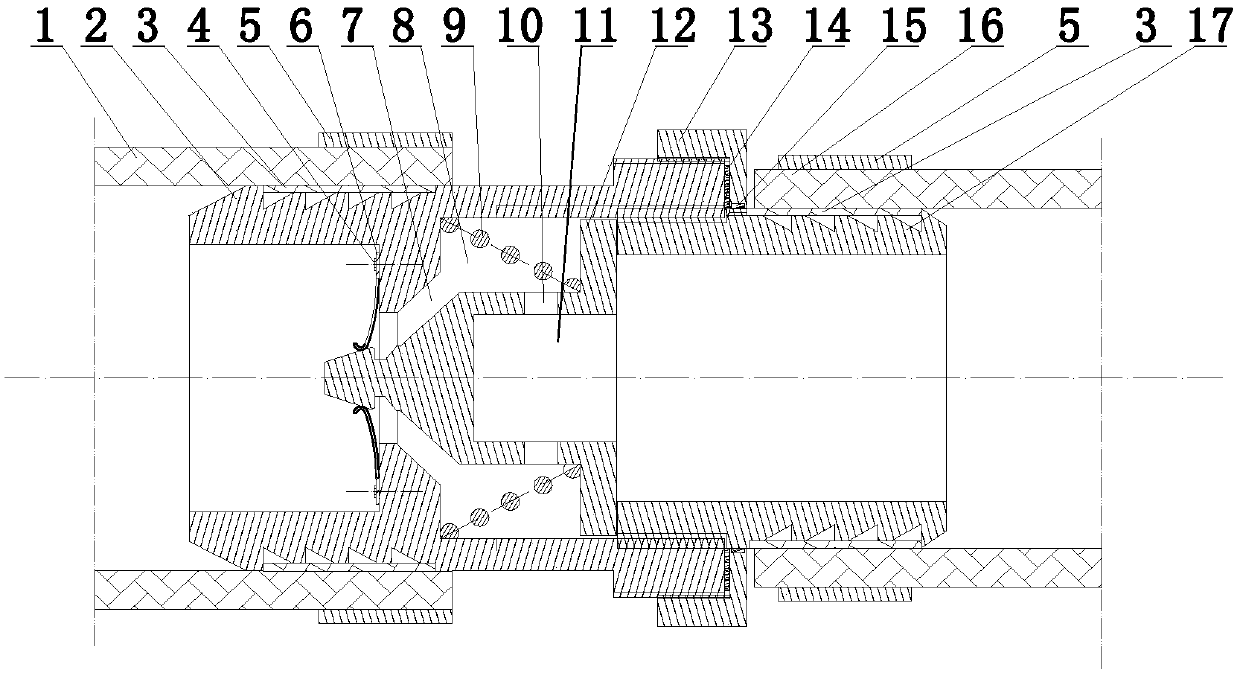

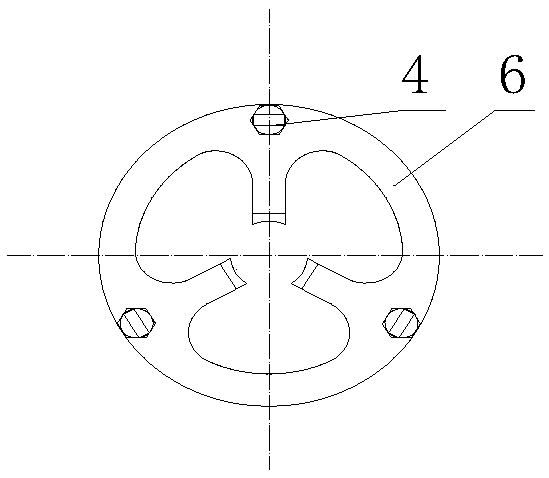

[0025] like Figure 1-2 As shown, a self-locking flow control valve in this embodiment includes a main body, the main body is a cylindrical structure, a branch pipe 1 is connected to the left side of the main body, and a main pipe 16 is connected to the right side of the main body; the above-mentioned main body It is composed of pipe head piece 2, valve core 12, curved shrapnel 6 and stack spring 9; pipe head piece 2 is a structure with a trumpet-shaped closing opening in the inner hole, and pipe head piece 2 is inserted at the port of branch pipe 1, and the main pipe In the end hole of 16, be connected with main pipe head piece 17, and main pipe head piece 17 is the construction of a left-hand outer diameter band tapered mouth. The above-mentioned pipe head piece 2 and the main pipe head piece 17 are screwed through the nut 13; the middle part of the pipe head piece 2 is provided with an inward boss, and the left end surface of the inner boss is provided with evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com