Supersonic nozzle jet mixing experiment device

An experimental device and supersonic technology, applied in jet engine testing, gas turbine engine testing, etc., can solve the problems of inability to simulate air injection mixing experiments, test jet parameters and flow field visualization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

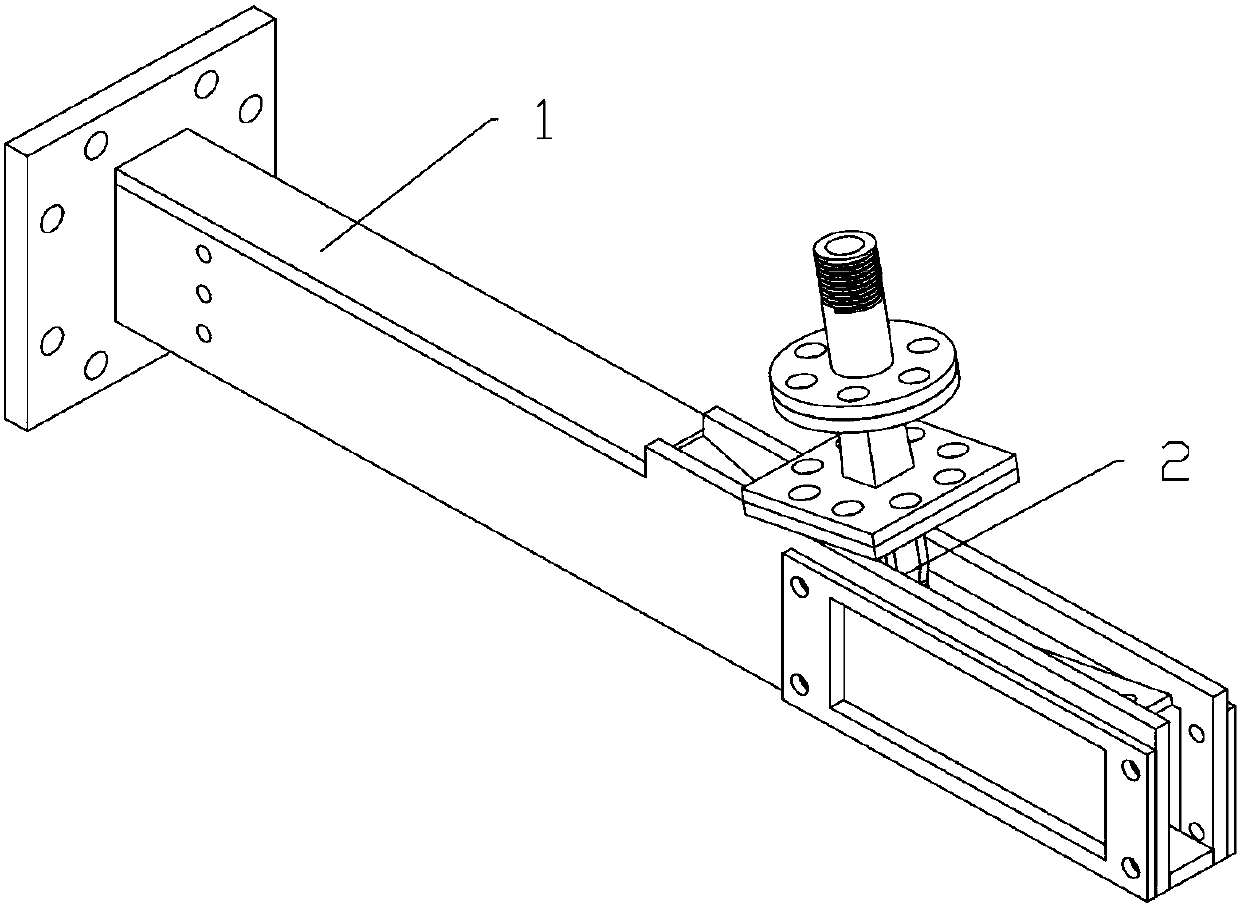

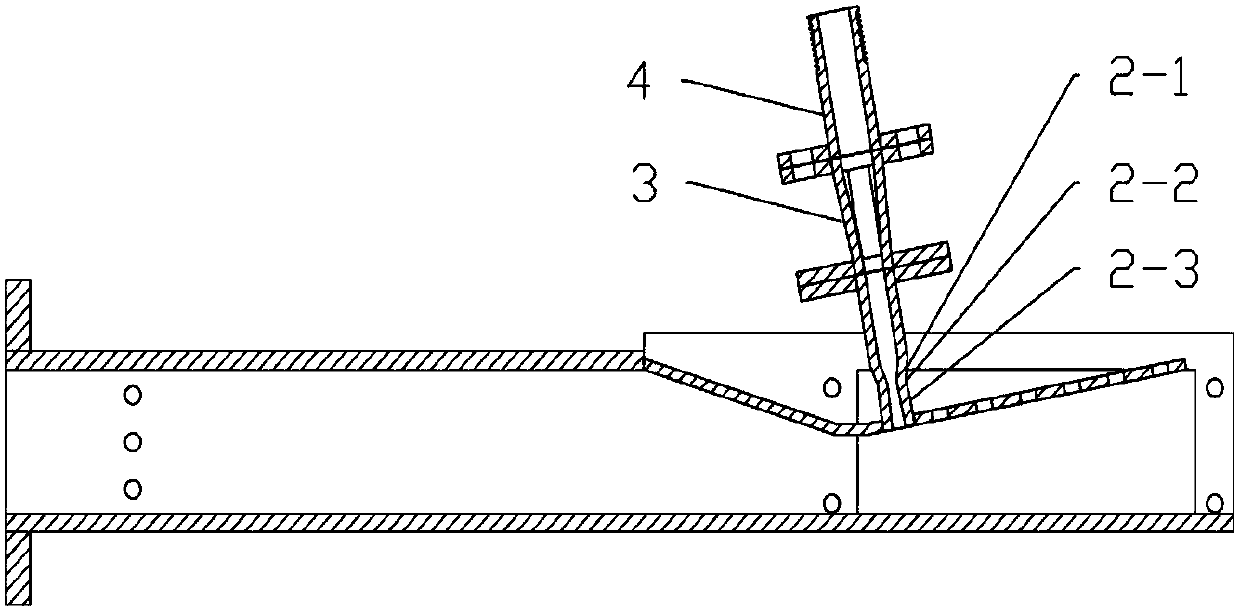

[0027] combine figure 1 , a supersonic nozzle jet mixing experimental device of the present invention, comprising a main flow nozzle 1 and a jet nozzle 2;

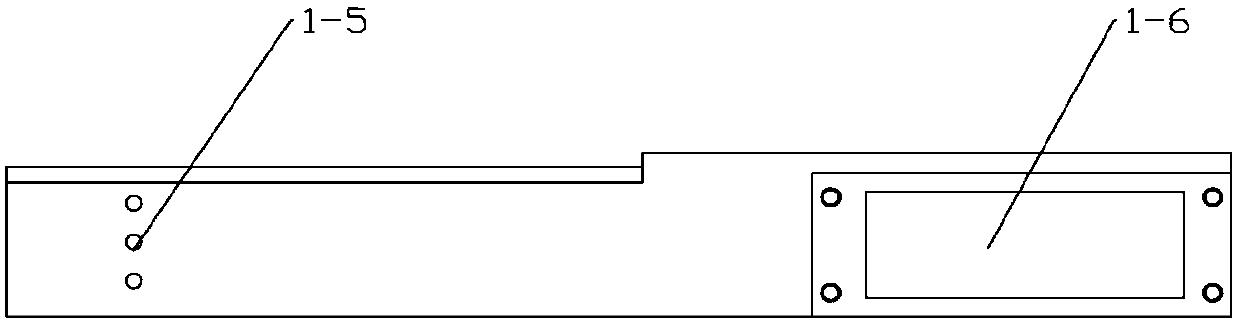

[0028] combine Figure 2-Figure 5 , the main flow nozzle 1 is a rectangular tube structure, and the rectangular tube is convenient to observe the wave system structure of the flow field relative to the circular tube; one end of the rectangular tube is provided with a flange, which is used as the jet inlet port, which is convenient to communicate with the external experimental device connection; and there are a plurality of round holes 1-5 on both sides of the inlet, and pressure sensors and thermocouples are arranged on the round holes 1-5; the pressure sensors are used to test the total pressure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com