Liquid crystal screen safety disassembling prevention structure and method

A liquid crystal screen, security technology, applied in internal/peripheral computer component protection, nonlinear optics, instruments, etc., can solve problems such as destroying FPC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

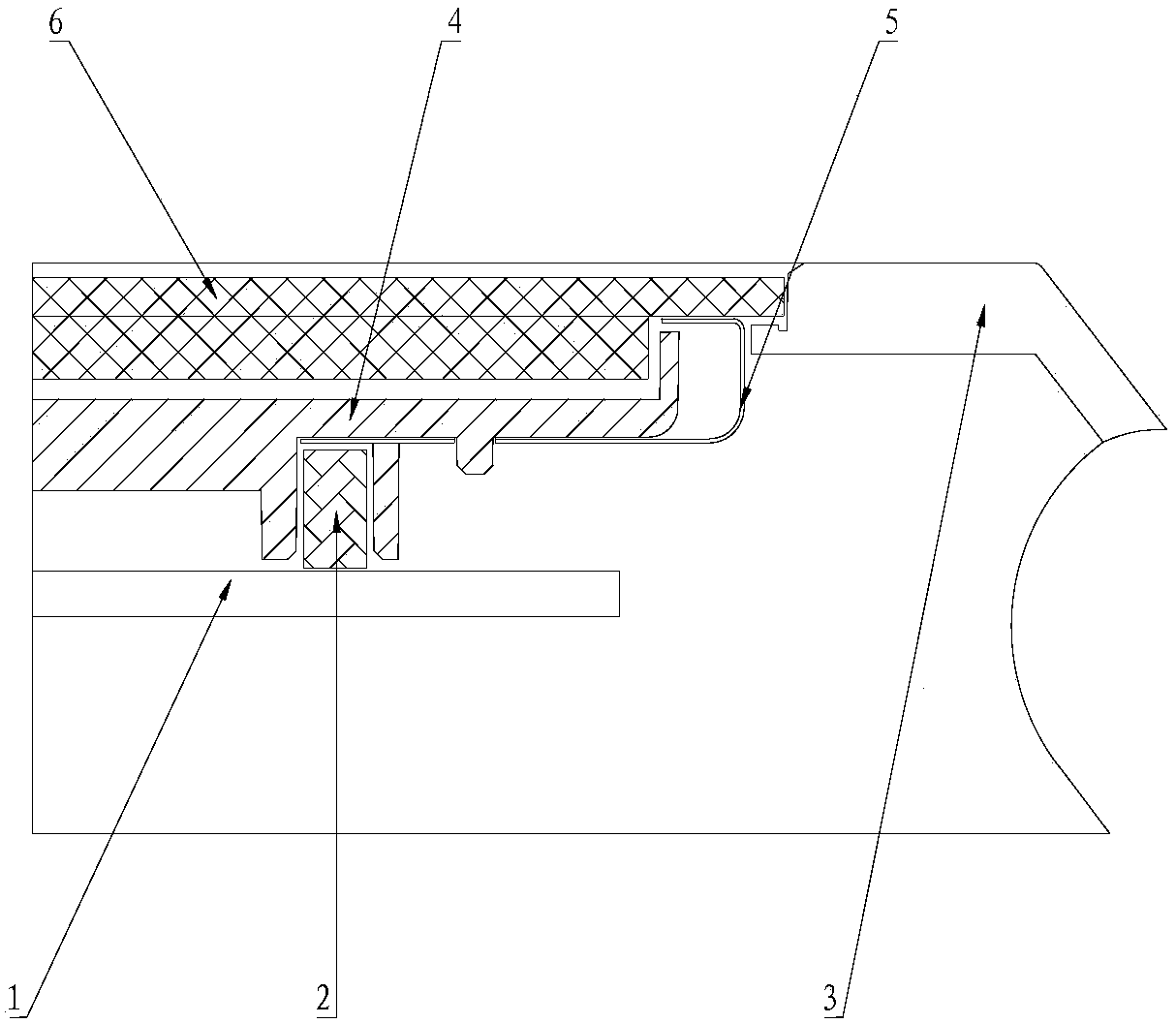

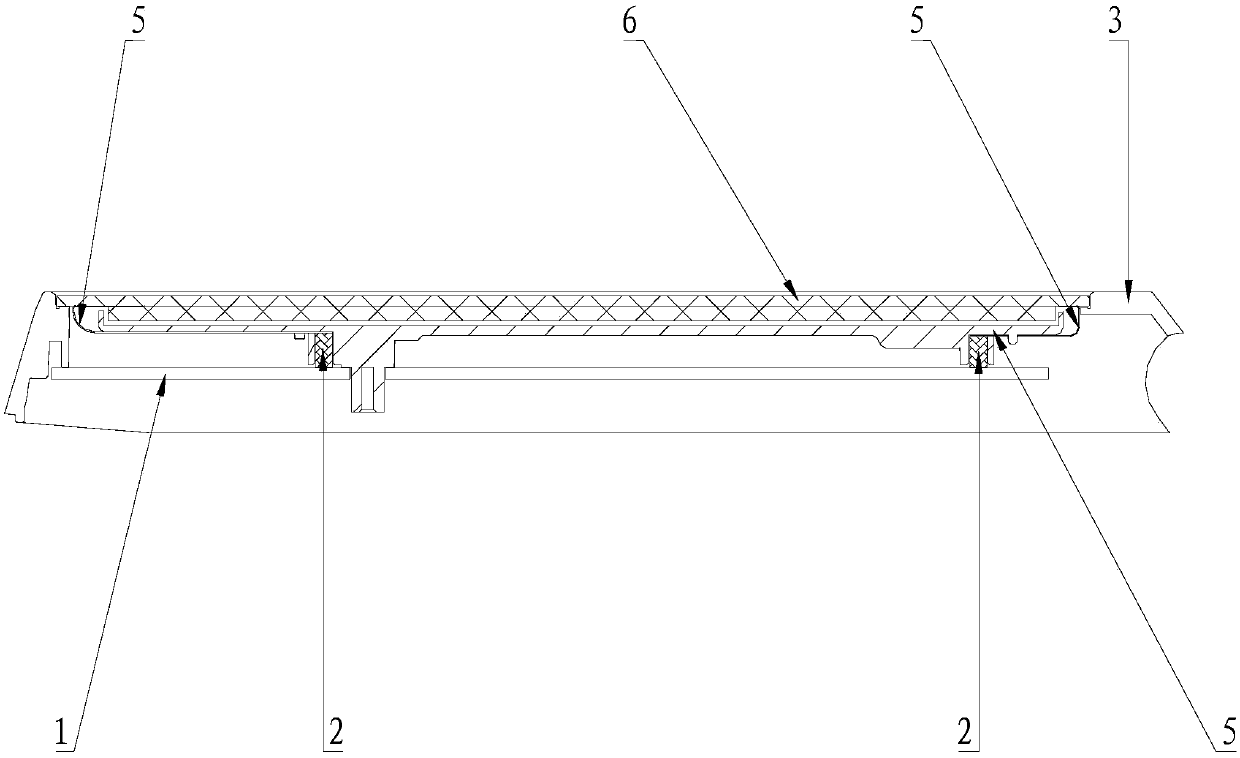

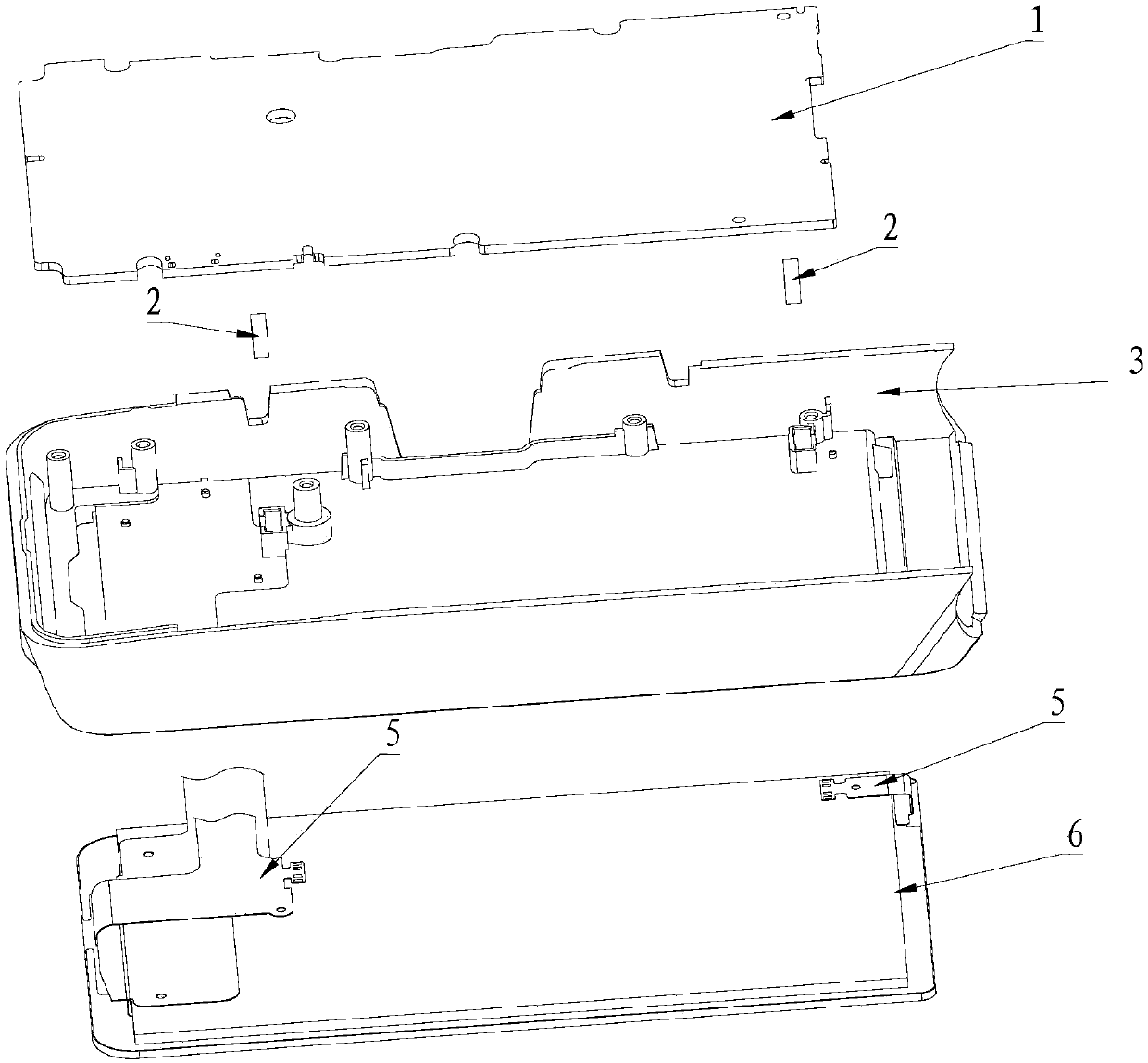

[0054] A safety tamper-proof structure of a liquid crystal screen, including a safety line, a PCB board 1, a zebra strip 2 and an FPC5, and a limiting structure 4;

[0055] The safety line is etched on the edge of the liquid crystal screen 6, drawn out through the FPC5 and extended to the position-limiting structure 4;

[0056] Since the glass at the edge of the LCD screen 6 is relatively fragile, it is easy to damage the glass at the edge of the LCD screen 6 when it is disassembled, which will trigger the safety mechanism and improve safety;

[0057] The limiting structure 4 limits the movement of the FPC5;

[0058] The other end of the FPC5 is connected to one end of the zebra strip 2;

[0059] The FPC5 is connected to the zebra strip 2 through the gold finger, the FPC5 is a flexible circuit board, and the zebra strip 2 is a block shaped conductive rubber;

[0060] The other end of the zebra strip 2 is connected to the PCB board 1;

[0061] By setting PCB contacts on the...

Embodiment 2

[0067] The difference between the second embodiment and the first embodiment is that several conductive channels are arranged in the zebra strip 2, and contacts corresponding to the conductive channels are provided. When the conductive channels are turned on, the corresponding contacts are connected to the The PCB board 1 is connected, and the conduction channel of the zebra strip 2 has different conduction resistances under different pressures;

[0068] The number of conductive channels in the zebra strip 2 is 8-10, and the above is only a specific implementation of the scheme, and changing the number of conductive channels in the zebra strip 2 also belongs to the scope of patent protection of the present invention.

Embodiment 3

[0070] The difference between the third embodiment and the first embodiment is that the limiting structure 4 is rectangular and placed horizontally, its width is adapted to the width of the FPC5, and its length is adapted to the length of the extension of the FPC5 on it;

[0071] A vertical upward extension is provided at one end of the position-limiting structure 4 along the length direction;

[0072] The end of the vertically upward extension away from the limit structure 4 is against the connection between the FPC and the edge of the liquid crystal screen 6, and the FPC5 is close to the vertically upward extension and extends to the limit structure 4;

[0073] A vertically downward extension is provided at the other end of the position-limiting structure 4 along the length direction;

[0074] The length of the vertically downward extension is less than the length of the zebra strip 2;

[0075] A protrusion is provided on the edge of the width direction on the side where t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com