Spraying method of container mark

A technology for containers and signs, which is applied to coatings and devices for coating liquid on the surface, etc., can solve the problems of inability to ensure uniform thickness of sign spray paint, low pass rate of spray mark, large production space, etc., to achieve mechanical automation operations, High degree of product uniformity and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

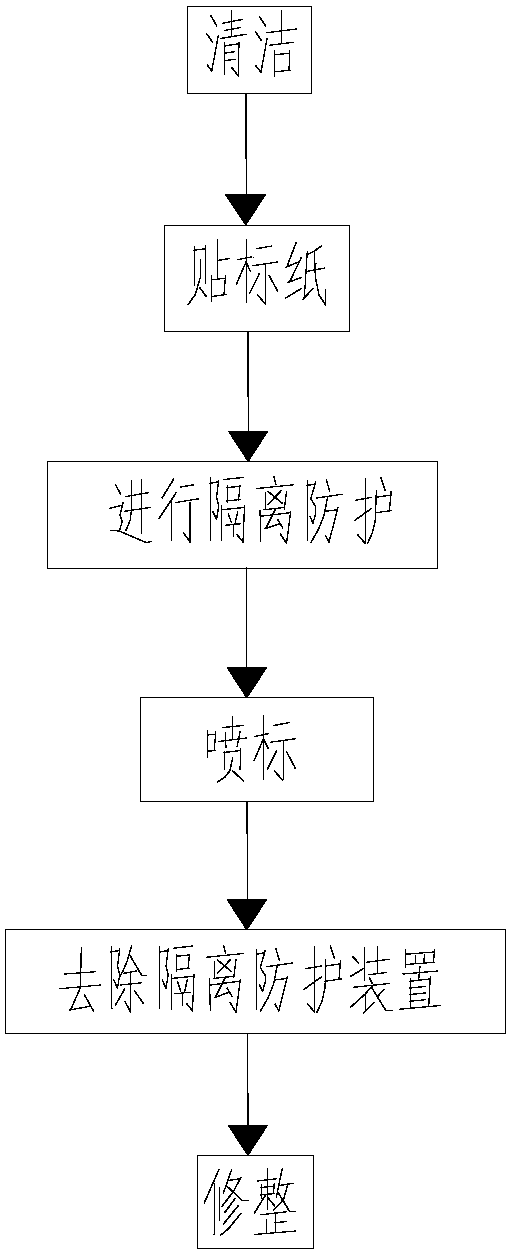

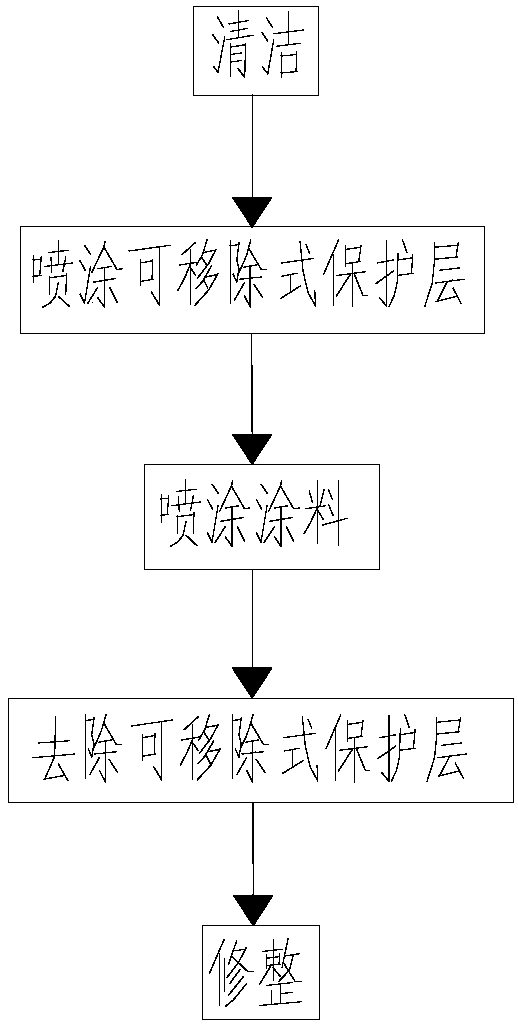

[0020] Such as figure 2 Shown, the present invention provides a kind of container mark spraying method, comprises the steps:

[0021] Step 1: Spray the removable protective layer. Spray the removable protective layer on the area of the preset spray mark on the outer surface of the container. The removable protective layer can isolate the paint and prevent the paint from covering the container body When spraying, the nozzle sprays along all the contour lines of the mark to the outer area of the contour line. After the spraying is completed, a removable protective layer with a hollow mark is formed in the area where the mark is sprayed;

[0022] Step 2: Spray the paint. After the removable protective layer is cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com