Mechanical arm and laser processing equipment

A technology of manipulators and manipulators, applied in laser welding equipment, metal processing equipment, manipulators, etc., can solve the problems of inconsistency in the direction of silicon wafer transmission, rising, and difficulties in the screen printing process, so as to facilitate transmission and processing and ensure transmission The effect of simple direction and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

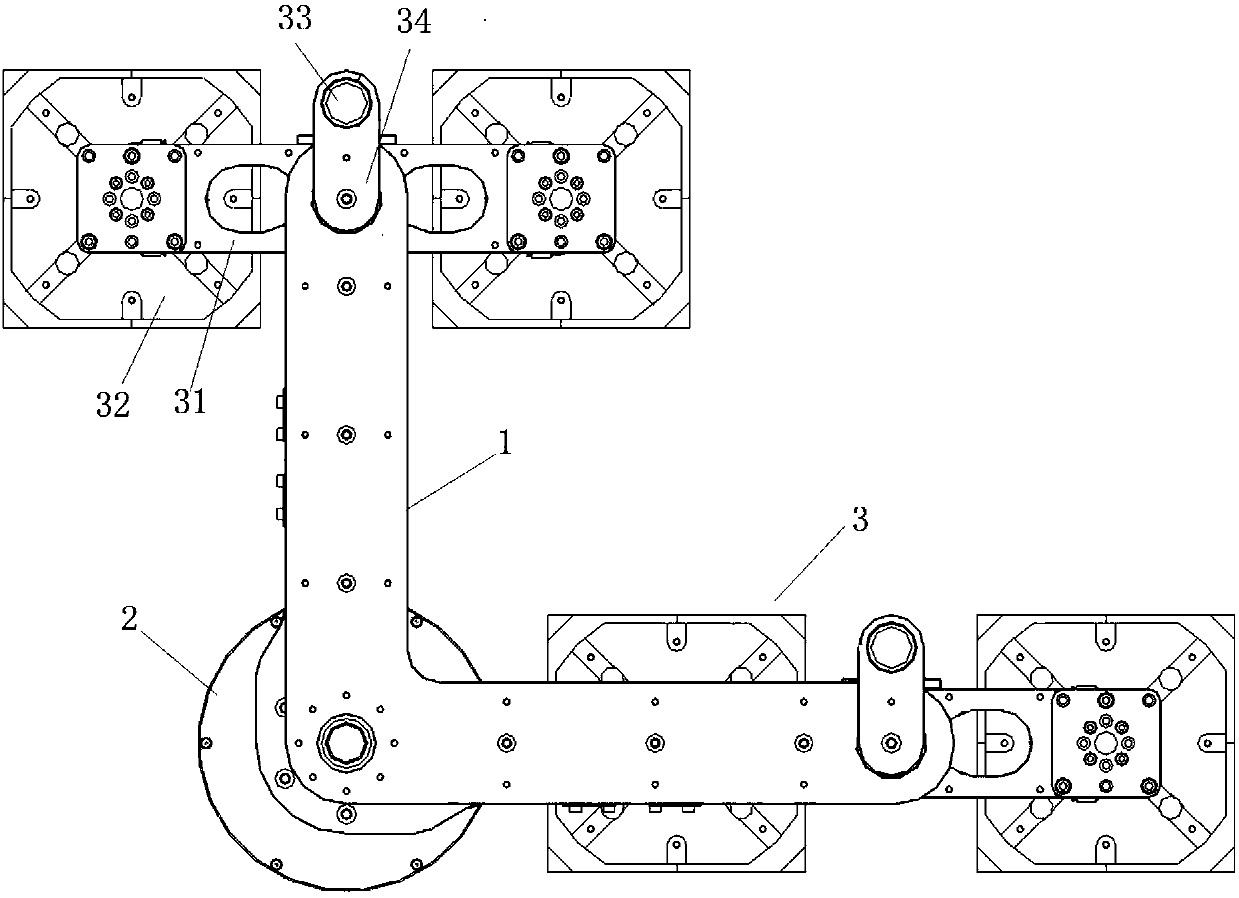

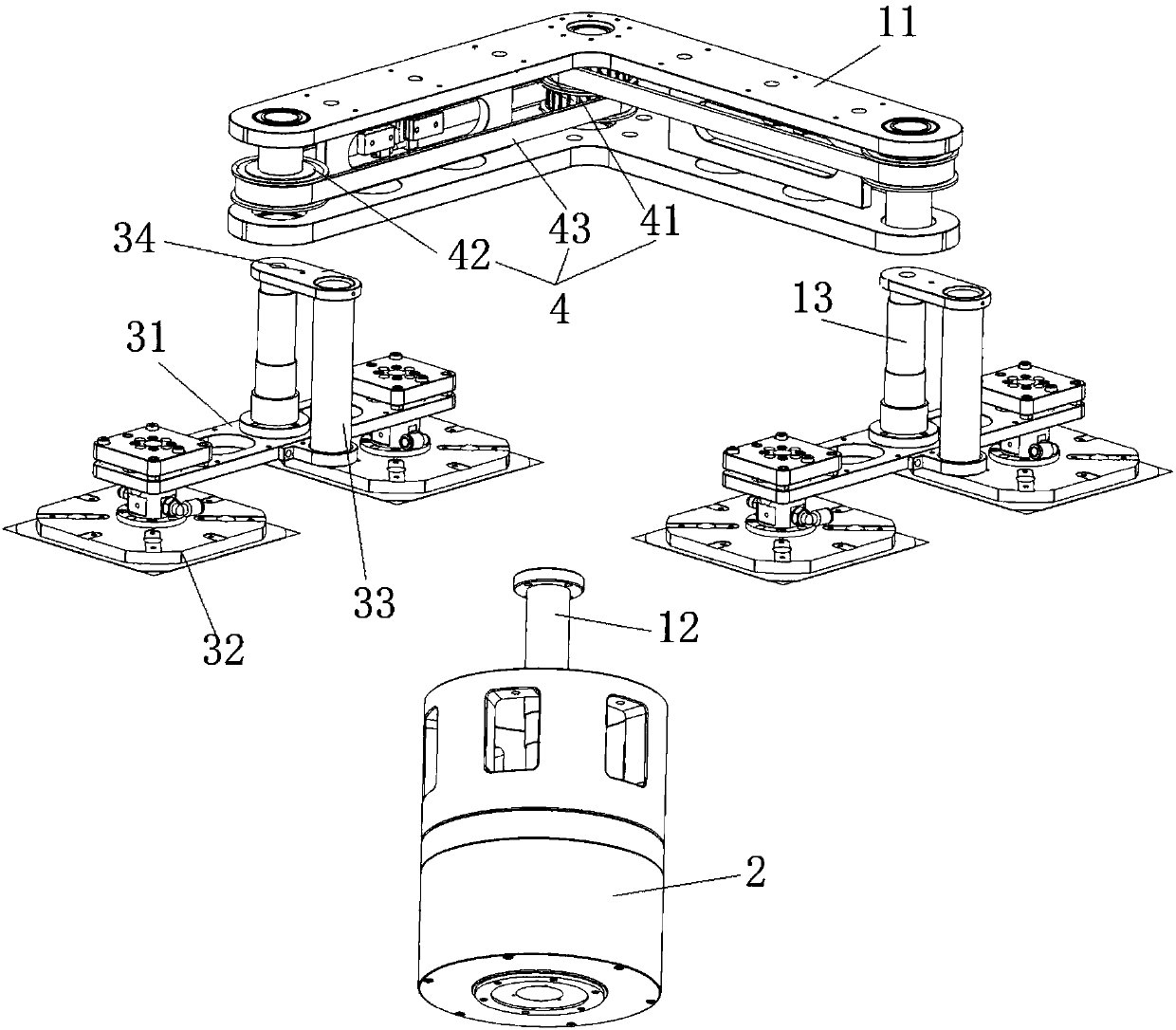

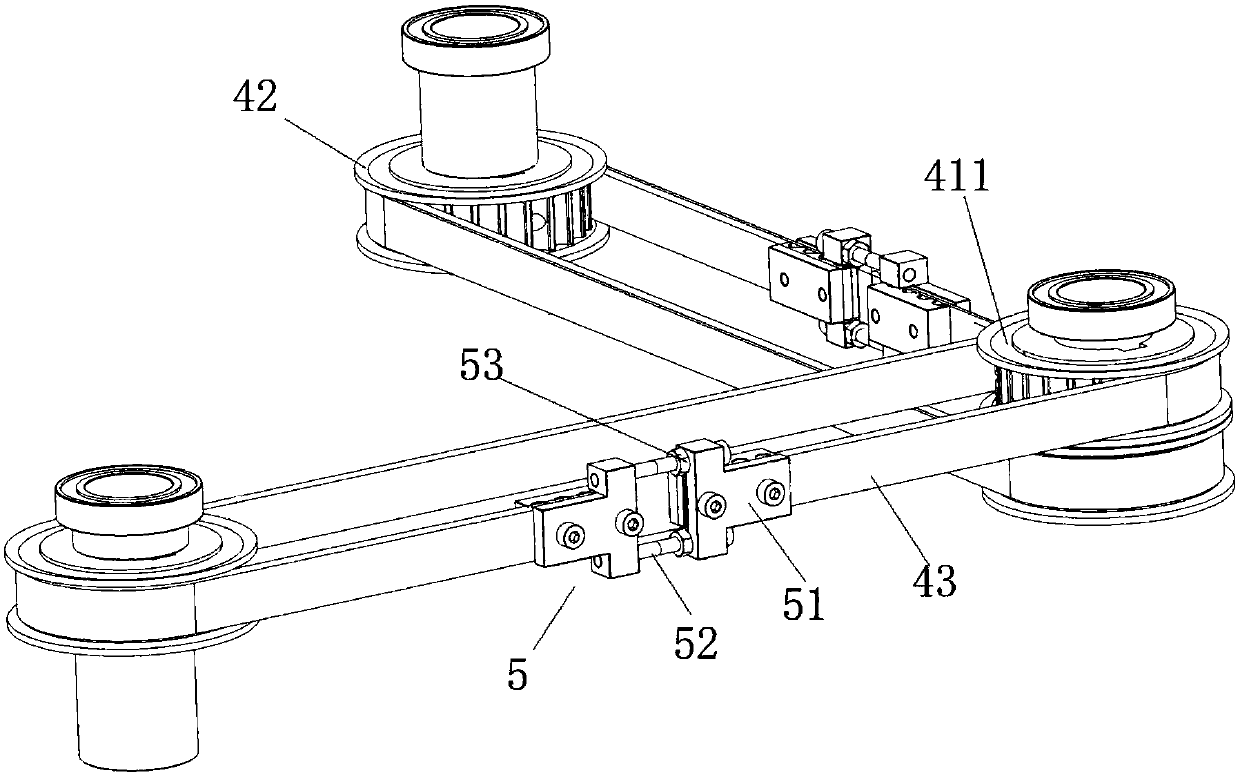

[0035] Embodiment one: if Figures 1 to 3 As shown, the manipulator of this embodiment includes a rotating arm 1, a driving device 2 and a suction cup assembly 3, the driving end of the above-mentioned driving device 2 is arranged vertically upward, the above-mentioned rotating arm 1 is horizontally installed on the driving end of the above-mentioned driving device 2, and the above-mentioned suction cup The assembly 3 is horizontally and rotatably arranged on the free end of the above-mentioned rotating arm 1, and is connected with the driving end of the above-mentioned driving device 2 through the transmission mechanism 4, and the above-mentioned driving device 2 can respectively drive the above-mentioned rotating arm 1 and the suction cup assembly 3 through the above-mentioned transmission mechanism 4 Synchronous reverse rotation.

[0036] Driven by the driving device 2, the synchronous reverse rotation of the rotating arm 1 and the suction cup assembly 3 is realized, ensuri...

Embodiment 2

[0047] Embodiment two: if Figure 4 and 5 As shown, the laser processing equipment of this embodiment includes a feeding and conveying assembly 18, an unloading and conveying assembly 19, a laser processing host 21, a cell processing table 20 and a workbench 22, the above-mentioned feeding and conveying assembly 18, the unloading and conveying assembly 19 1. The laser processing host 21 and the cell processing table 20 are respectively installed on the above-mentioned workbench 22. The above-mentioned laser processing host 21 is located above the above-mentioned cell processing table 20, and also includes the above-mentioned manipulator in Embodiment 1. The above-mentioned manipulator is installed on the above-mentioned workbench. On the platform 22, and located on one side of the above-mentioned cell sheet processing platform 20, the above-mentioned feeding and conveying assembly 18 and the above-mentioned unloading and conveying assembly 19 are respectively installed on the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap