Bi-color artificial leather capable of preventing evaporative heat loss

A technology of artificial leather and evaporative heat, which is applied in the field of artificial leather, can solve the problems of single pattern and color, and achieve the effects of good sanitation, prevention of evaporative heat loss, and good comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

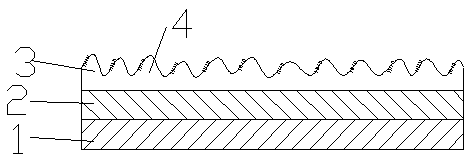

[0012] See figure 1 , The present invention relates to a two-color artificial leather to prevent evaporation heat loss, comprising a substrate layer 1 and a surface layer 2. The substrate layer 1 is made of woven cloth, the surface layer 2 is made of PVC plastic, and the upper surface of the surface layer 2 is provided There is a decorative layer 3 which is made of polyurethane resin, and the upper surface of the decorative layer 3 has spaced strip-shaped protrusions 4. The surface layer 2 is provided with a decorative layer 3 of strip-shaped protrusions 4, so that when spraying colors, it can be sprayed from the side of the strip-shaped protrusions 4, so that the front side of the strip-shaped protrusions 4 is colored, and the other side is natural. The artificial leather has two colors, and the color is no longer single and layered.

[0013] The surface layer 2 is composed of the following raw materials in parts by weight: 36 to 45 parts of polyvinyl chloride resin; 18 to 26 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com