Multi-area type anti-skid safety shoe sole

A technology for safety shoes and soles, which is applied in the field of safety shoes soles. It can solve the problems of lack of comfort of safety insoles and achieve the effects of strong grip, reduced wear, and improved anti-skid friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

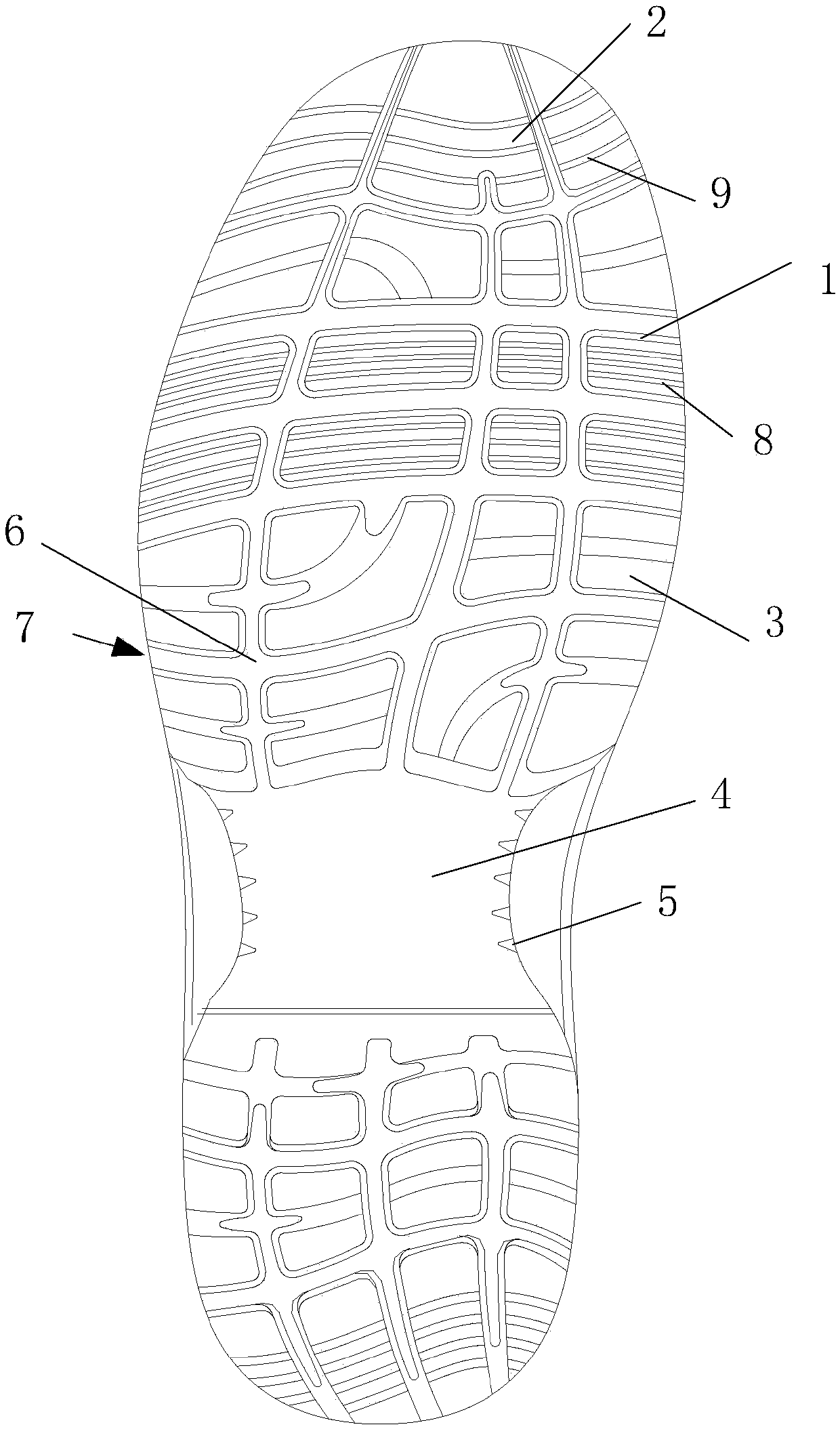

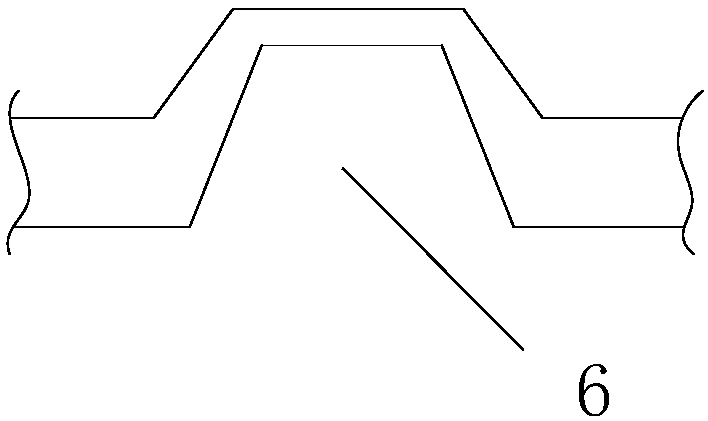

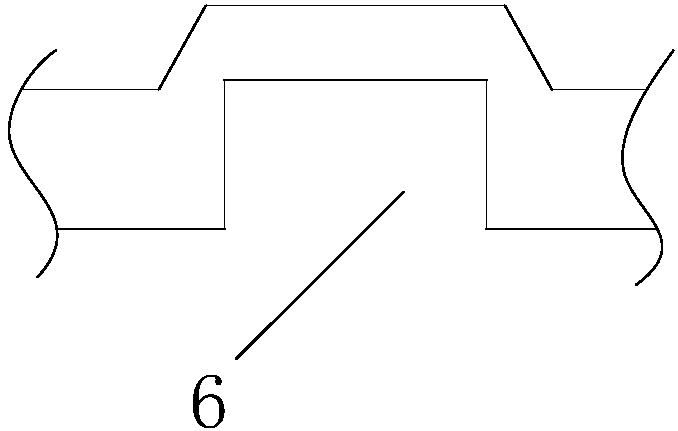

[0033] Such as Figures 1 to 3 A multi-zone non-slip safety shoe sole, including the sole body, the sole body is divided into the forefoot part, the middle stepping part, and the heel part from front to back. And it has a better wearing comfort. The forefoot part includes a grid texture block 1. The front end of the grid texture block 1 is provided with several auxiliary corrugated blocks 2. The tail end of the grid texture block 1 is distributed with stepping Block 3. In this way, when the force is applied to the front end of the foot during walking, the cooperation of the grid pattern block 1 and the auxiliary corrugated block 2 can bear the stepping stress and improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com