Distributor for feeding dish washing powder in closed mode

A technology of dispenser and dishwashing powder, applied in the direction of washing machine/rinsing machine parts of tableware, etc., can solve problems such as noise and achieve the effect of avoiding noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

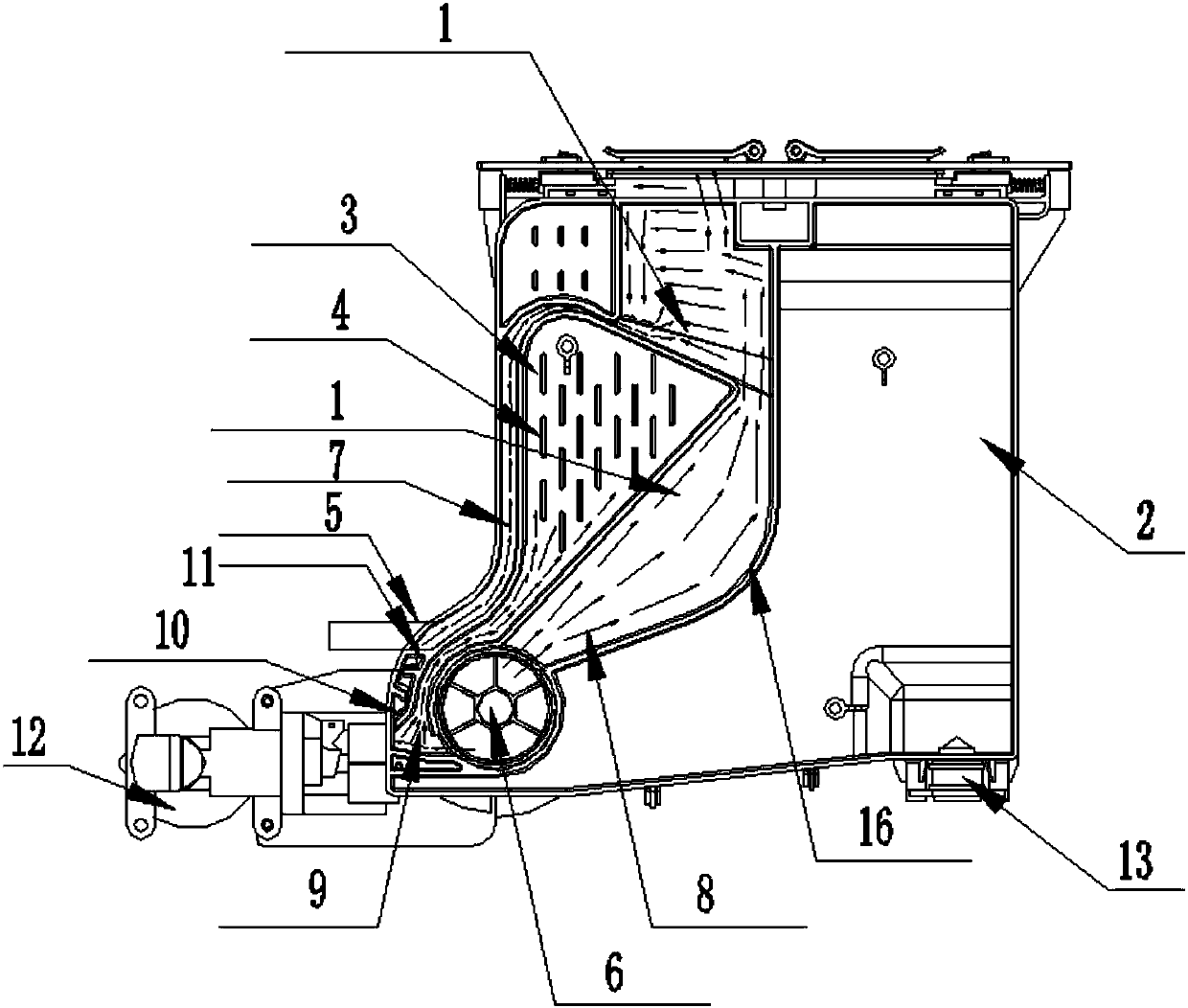

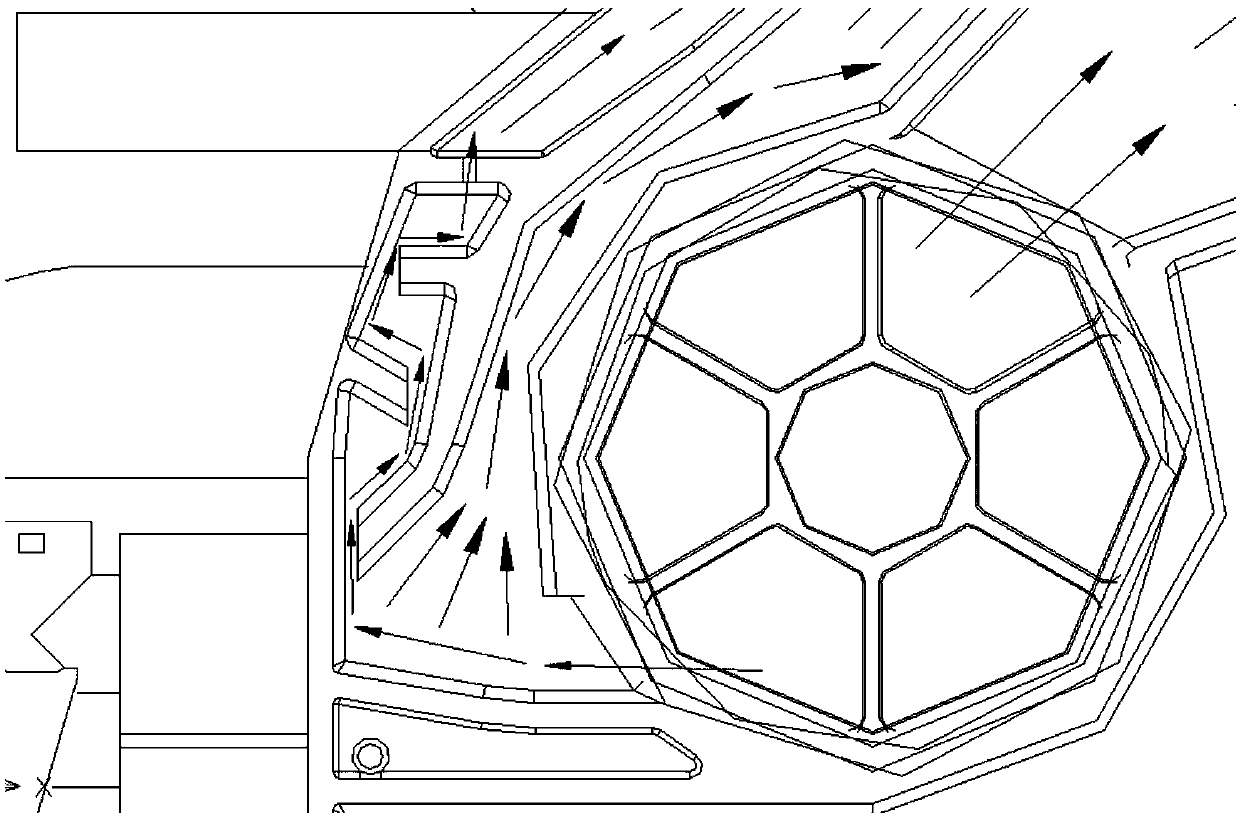

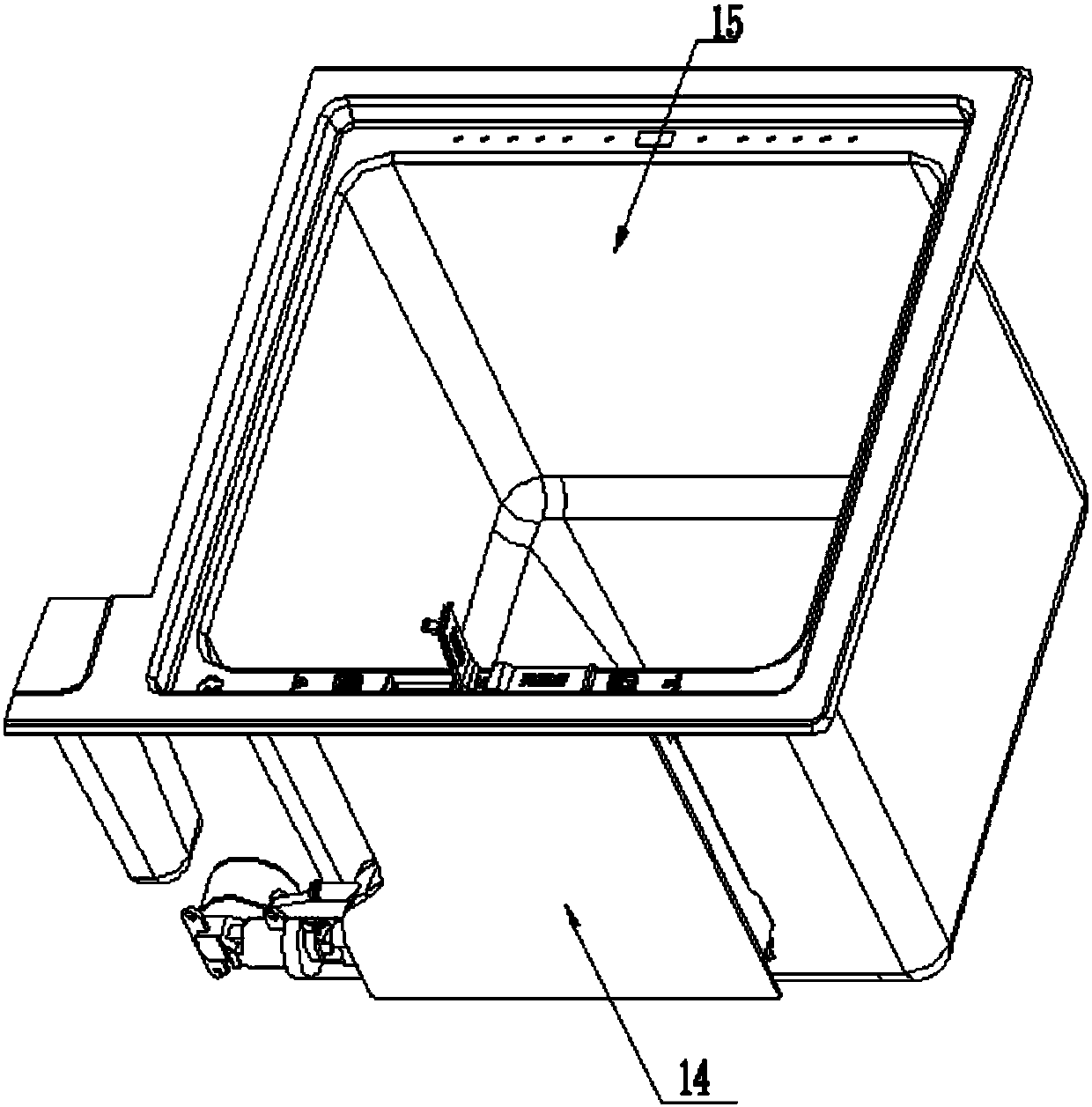

[0021] A kind of dishwashing powder provided by the present invention adopts the dispenser of closed feeding mode, and its specific structure is as follows: figure 1 with figure 2 As shown, the dispenser body 14 is primarily comprised. The interior of the dispenser body 14 is respectively provided with a dishwashing powder chamber 1, a rinse aid chamber 2 and an air chamber 3, wherein the dishwashing powder chamber 1 can be divided into an upper chamber and a lower chamber which communicate with each other, and the air chamber 3. It is arranged on one side of the lower cavity of the dishwashing powder. Along the other side of the air chamber 3, there is an upwardly roundabout water inlet channel 7, the water inlet end of the water inlet channel 7 communicates with the water inlet pipe 5 arranged on the distributor body 14, and the water outlet end of the water inlet channel 7 is along the air chamber. 3. The top is laid on the side that slopes downward. The water inlet cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com