An exterior wall painting device for working at heights

A high-altitude operation and exterior wall technology, which is applied to the device and coating of the surface coating liquid, which can solve the problems of waste of paint materials, high labor intensity of workers, and slow painting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

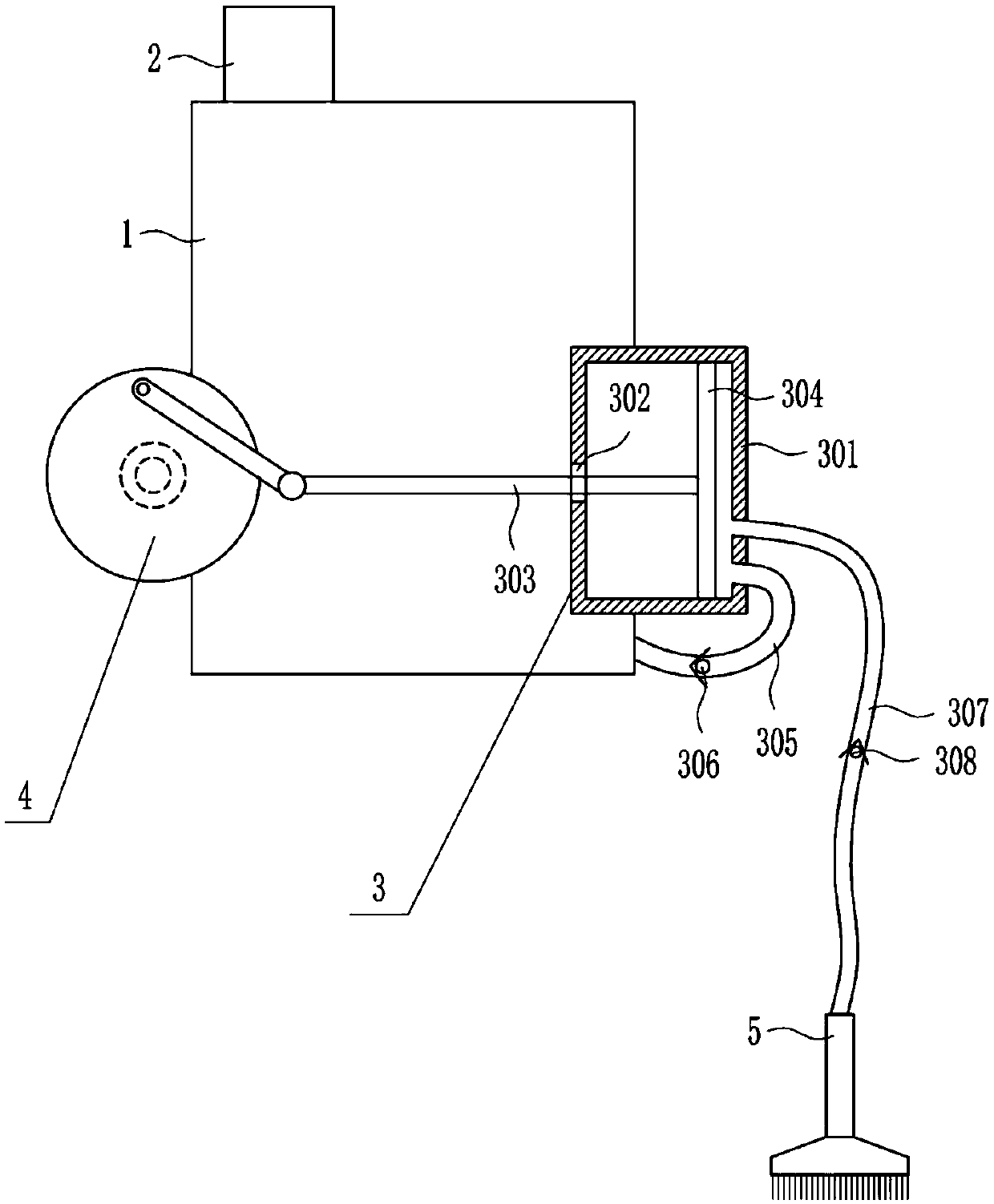

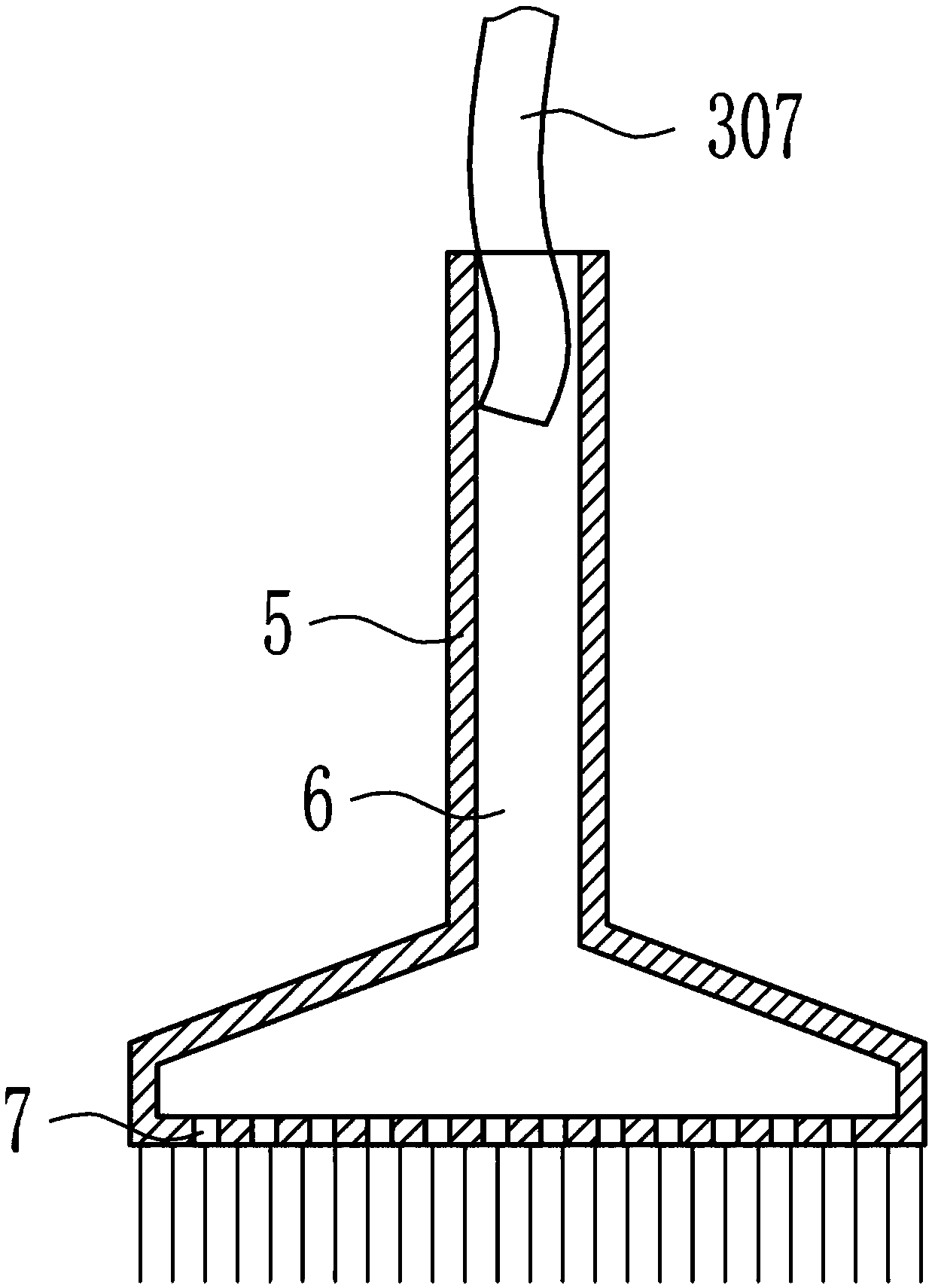

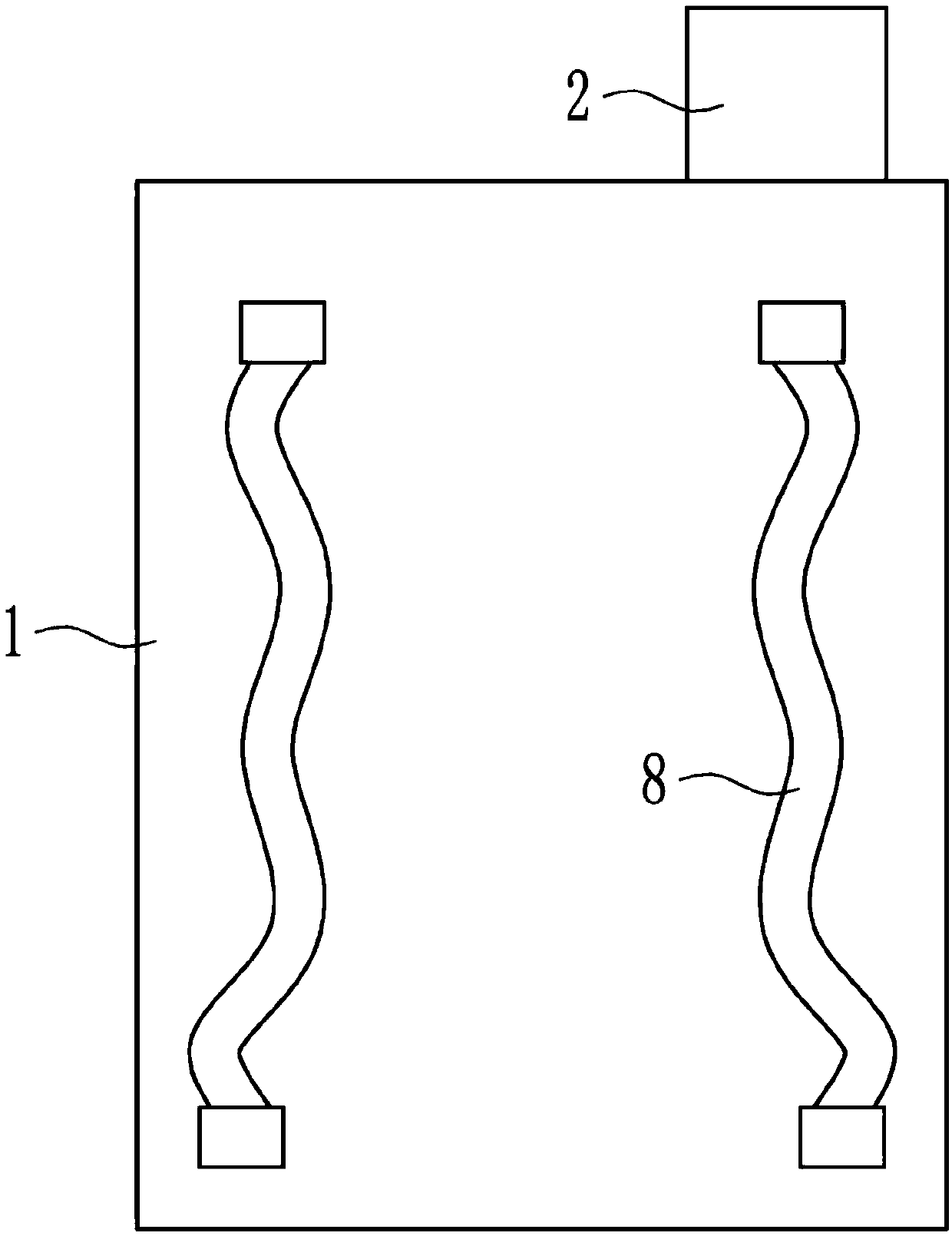

[0042] An exterior wall painting device for aerial work, such as Figure 1-12 As shown, it includes a cylinder body 1, a feeding tube 2, an infusion device 3, a driving device 4, a brush 5 and a strap 8. The top left side of the cylinder body 1 is connected to the feeding tube 2, and the front side of the cylinder body 1 is connected to the right side. An infusion device 3 is provided, a drive device 4 is provided on the left side of the cylinder body 1, a brush 5 is provided on the periphery of the infusion part of the infusion device 3, and a cavity 6 is opened in the brush 5, and the infusion part of the infusion device 3 is connected to the cavity 6, the bottom of the brush 5 is evenly spaced with a plurality of liquid outlet holes 7, the liquid outlet holes 7 communicate with the cavity 6, and the left and right sides of the rear side of the cylinder body 1 are provided with straps 8.

Embodiment 2

[0044] An exterior wall painting device for aerial work, such as Figure 1-12 As shown, it includes a cylinder body 1, a feeding tube 2, an infusion device 3, a driving device 4, a brush 5 and a strap 8. The top left side of the cylinder body 1 is connected to the feeding tube 2, and the front side of the cylinder body 1 is connected to the right side. An infusion device 3 is provided, a drive device 4 is provided on the left side of the cylinder body 1, a brush 5 is provided on the periphery of the infusion part of the infusion device 3, and a cavity 6 is opened in the brush 5, and the infusion part of the infusion device 3 is connected to the cavity 6, the bottom of the brush 5 is evenly spaced with a plurality of liquid outlet holes 7, the liquid outlet holes 7 communicate with the cavity 6, and the left and right sides of the rear side of the cylinder body 1 are provided with straps 8.

[0045] The transfusion device 3 comprises a cylinder body 301, a push rod 303, a pisto...

Embodiment 3

[0047] An exterior wall painting device for aerial work, such as Figure 1-12 As shown, it includes a cylinder body 1, a feeding tube 2, an infusion device 3, a driving device 4, a brush 5 and a strap 8. The top left side of the cylinder body 1 is connected to the feeding tube 2, and the front side of the cylinder body 1 is connected to the right side. An infusion device 3 is provided, a drive device 4 is provided on the left side of the cylinder body 1, a brush 5 is provided on the periphery of the infusion part of the infusion device 3, and a cavity 6 is opened in the brush 5, and the infusion part of the infusion device 3 is connected to the cavity 6, the bottom of the brush 5 is evenly spaced with a plurality of liquid outlet holes 7, the liquid outlet holes 7 communicate with the cavity 6, and the left and right sides of the rear side of the cylinder body 1 are provided with straps 8.

[0048] The transfusion device 3 comprises a cylinder body 301, a push rod 303, a pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com