A kind of tundish low oxygen level control method and device

A control method and tundish technology, applied in the field of continuous casting, can solve problems such as the cleanliness of the molten steel in the steel head furnace and the low quality of the cast slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

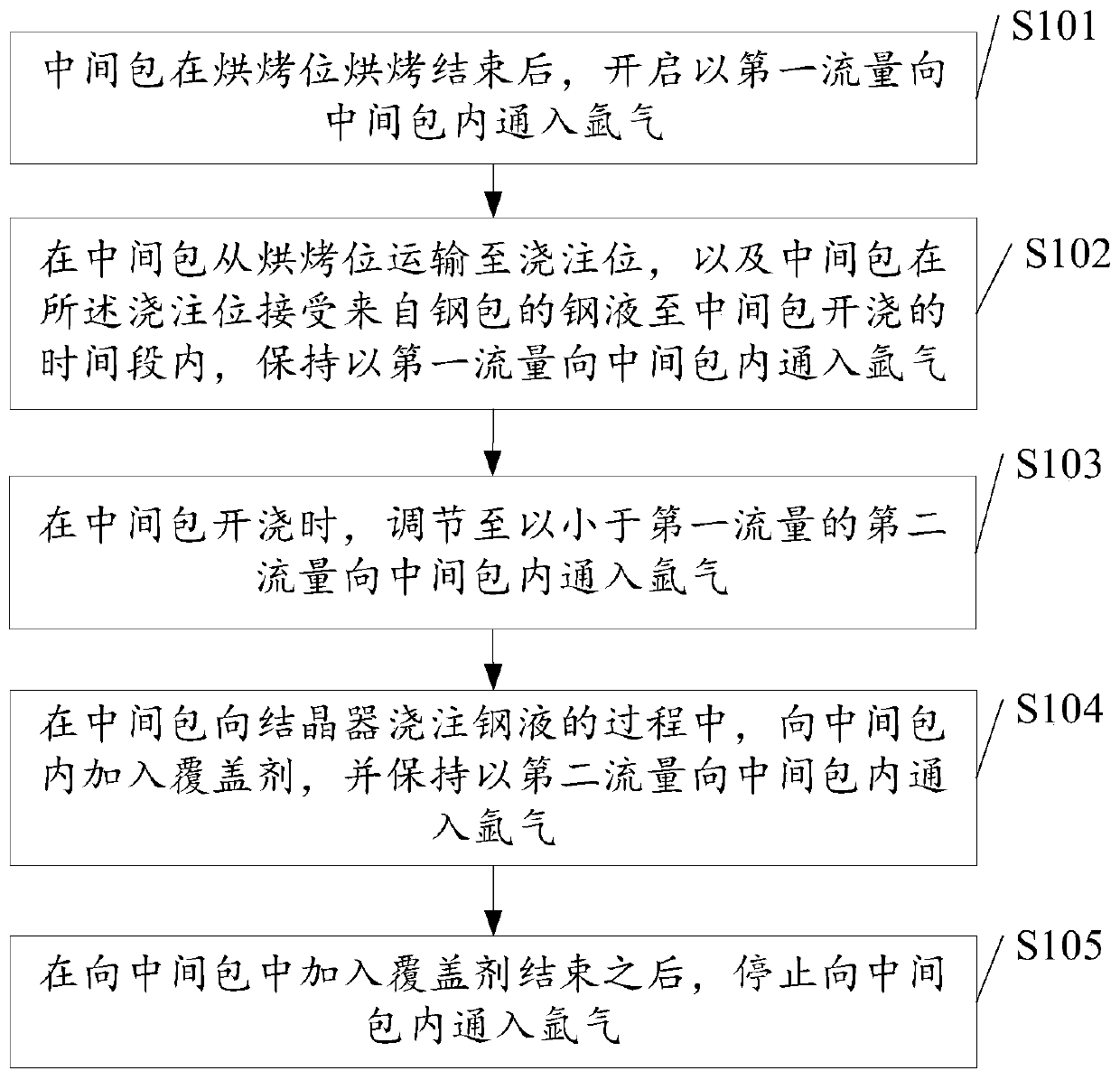

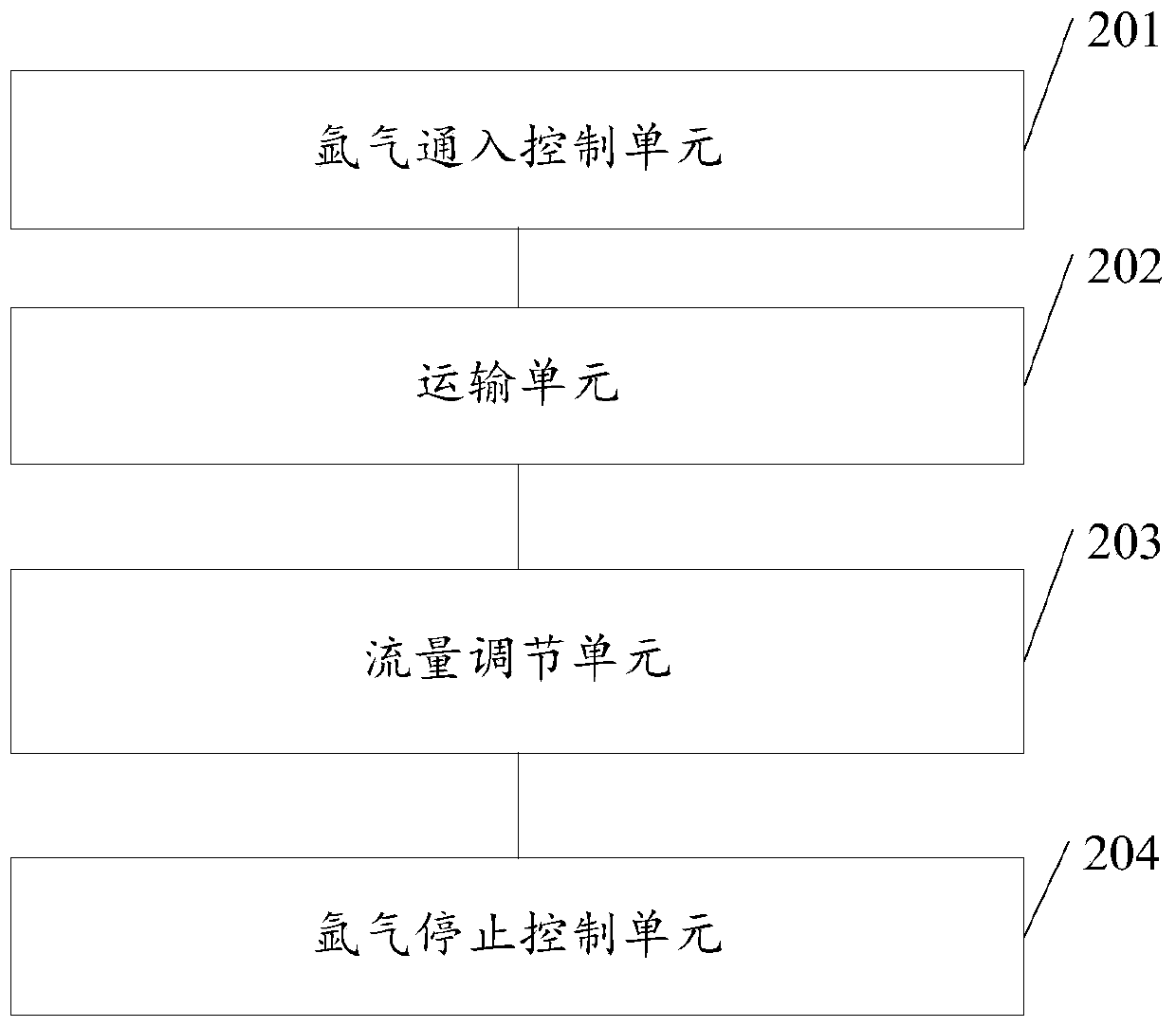

[0038] The embodiment of the present invention provides a method for controlling the low oxygen level of the tundish, which solves the technical problems of the cleanliness of molten steel in the head furnace and the low quality of the slab. The method for controlling the low oxygen level of the tundish provided by the embodiment of the present invention The general idea is as follows:

[0039] During the time period from the end of the tundish baking to the end of adding the covering agent into the tundish, argon gas is kept flowing into the tundish, thereby avoiding the contact of the molten steel surface of the tundish with air during the pouring process, so as to reduce the opening An oxidizing atmosphere is included in the pouring process to prevent the secondary oxidation of the exposed molten steel, so as to improve the cleanliness of the molten steel in the steel head furnace and the quality of the cast slab.

[0040] In order to better understand the above-mentioned t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com