Air outlet assembly and method for assembling air outlet system

An air outlet and assembly technology, applied in transportation and packaging, heating/cooling equipment, vehicle parts, etc., can solve problems that affect the appearance and hinder air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

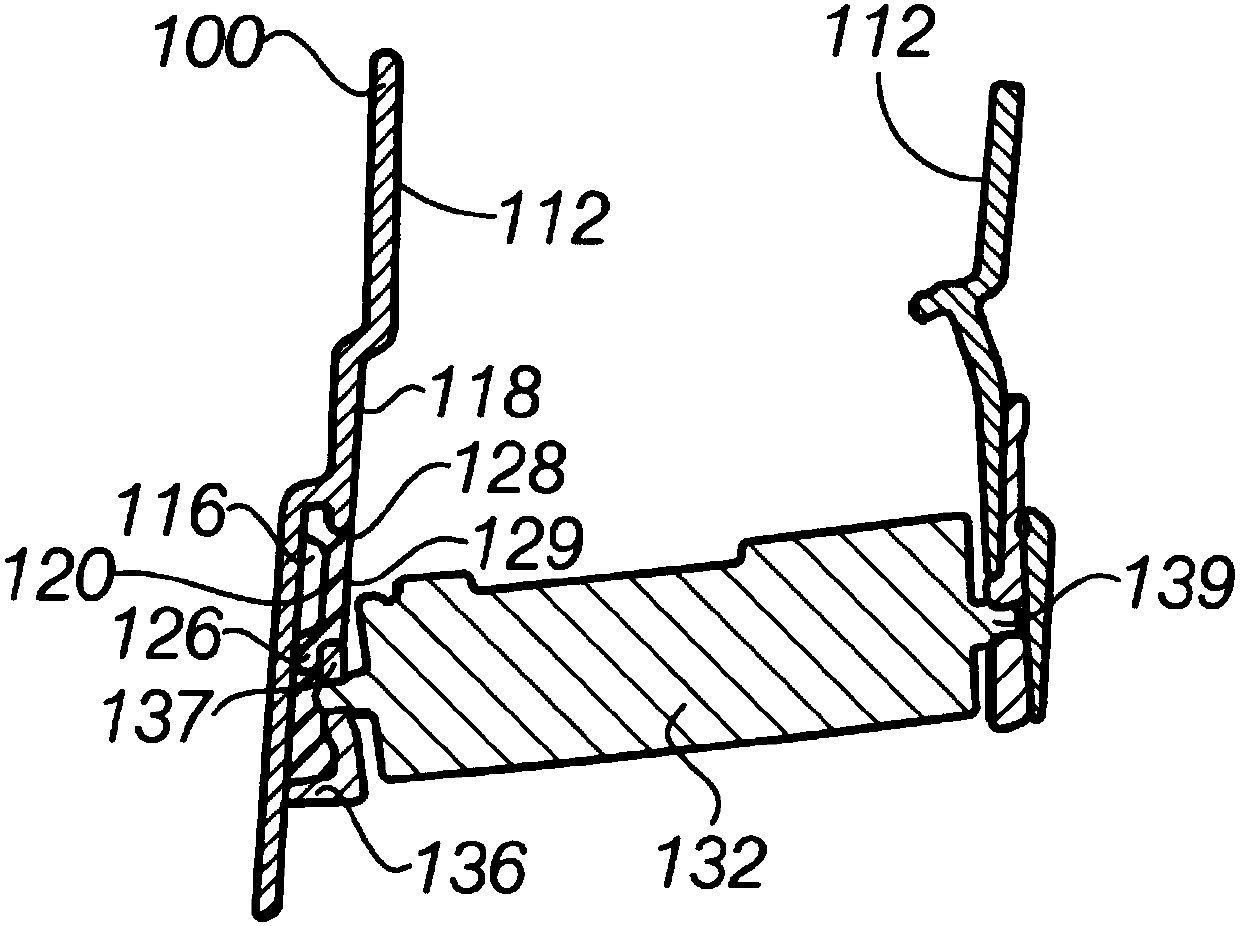

[0030] When referring to the drawings, please note that like numerals are used to refer to like parts. In the following description, different operating parameters and components are used to describe constructing different embodiments. These specific parameters and components are to be used as examples and not meant to be limiting.

[0031] The present invention embodied by one or more embodiments has significant advantages in improving the air outlet efficiency and aesthetics of the air outlet system. More specifically, the hidden slider and chute design can not only make the linkage rod that pushes the leaf to rotate invisible from the outside of the air outlet, making the design of the air outlet more concise and beautiful; Remove it from the path to reduce the wind resistance received by the circulating air at the air outlet, while still being able to achieve the function of adjusting the angle of the blades.

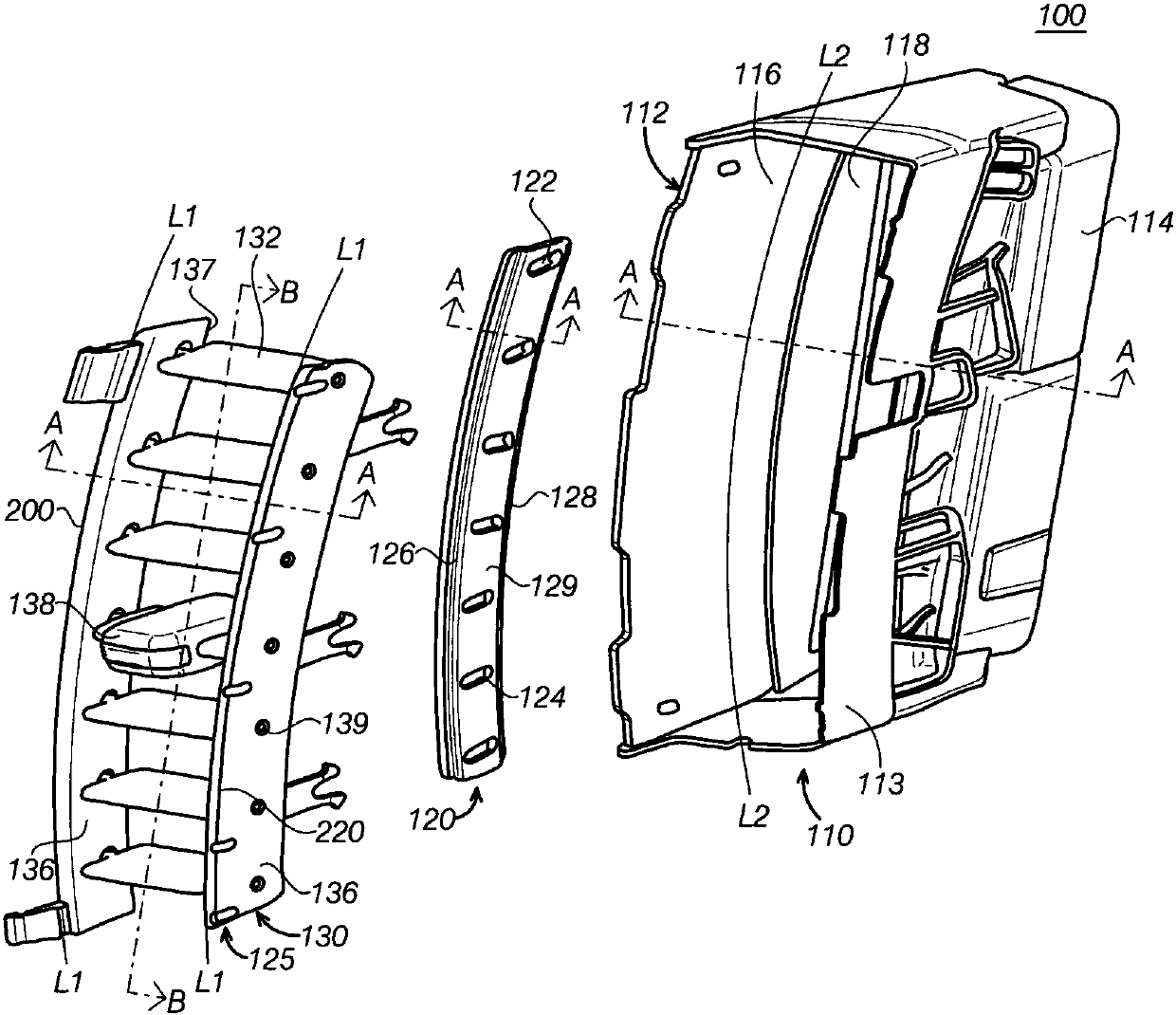

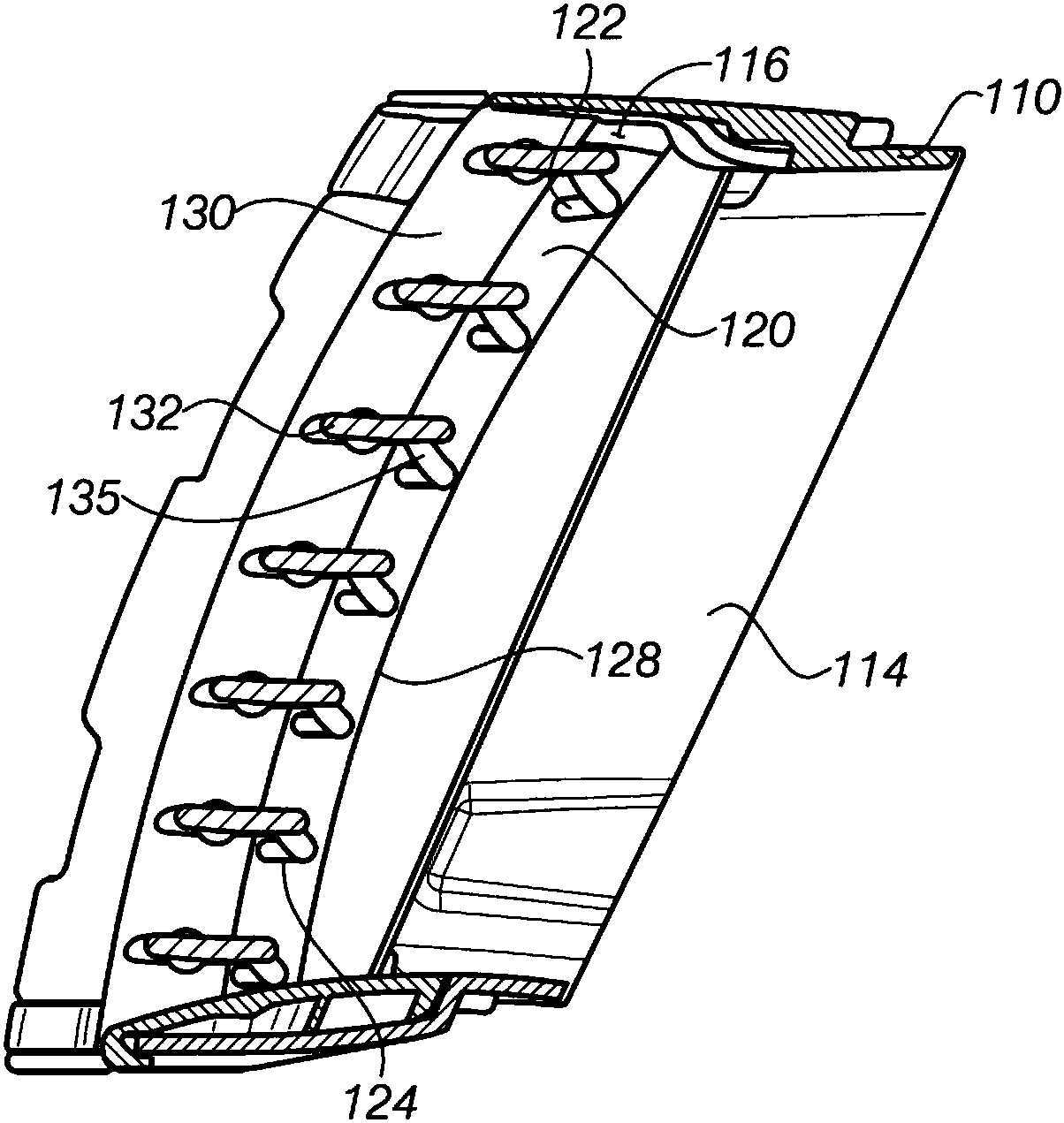

[0032] attached figure 1 It is an exploded perspective view...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com