Double-spring type winding equipment

A double spring and equipment technology, applied in the field of online or tube winding, can solve the problems of unbalanced force on the runner, unsteady speed changes, large, and can only be set in the disk body at one end of the runner, etc. The effect of balanced distribution, balanced force and stable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

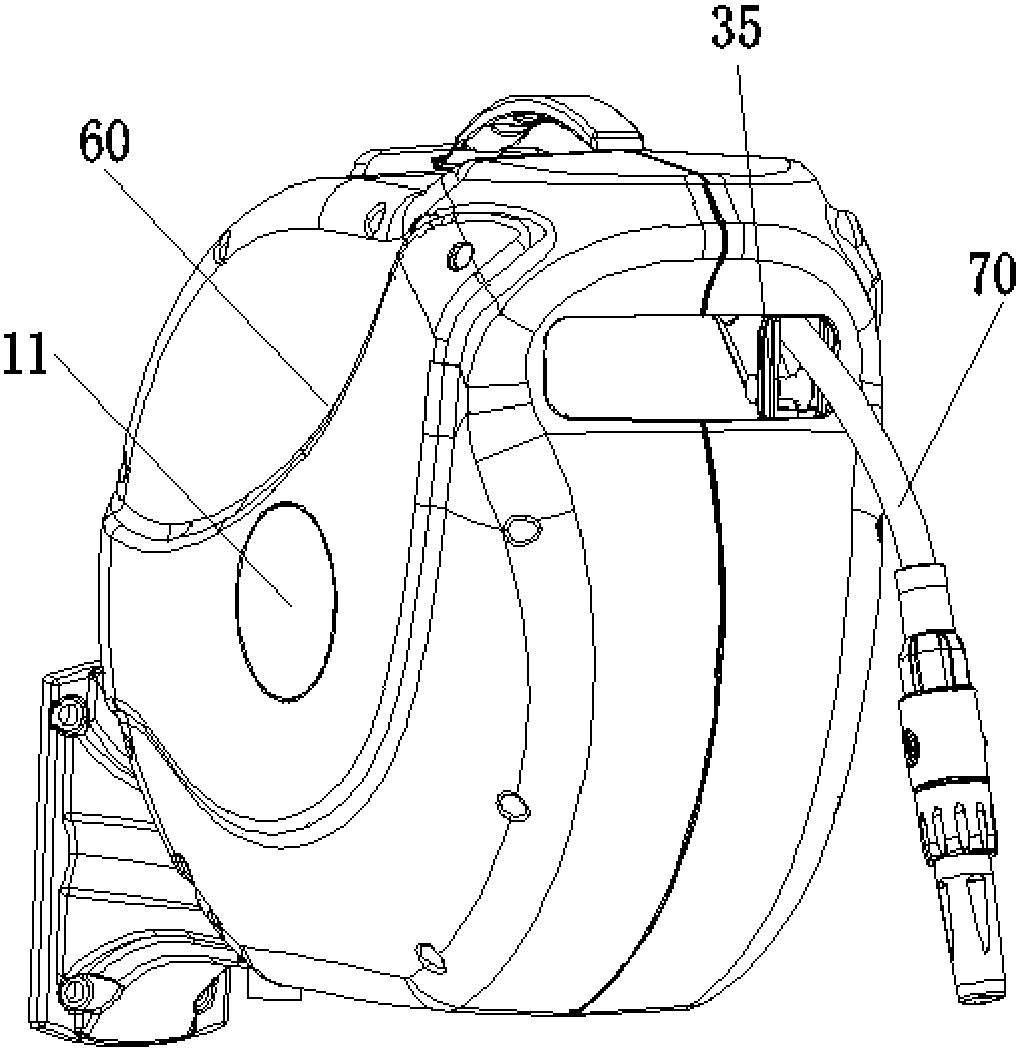

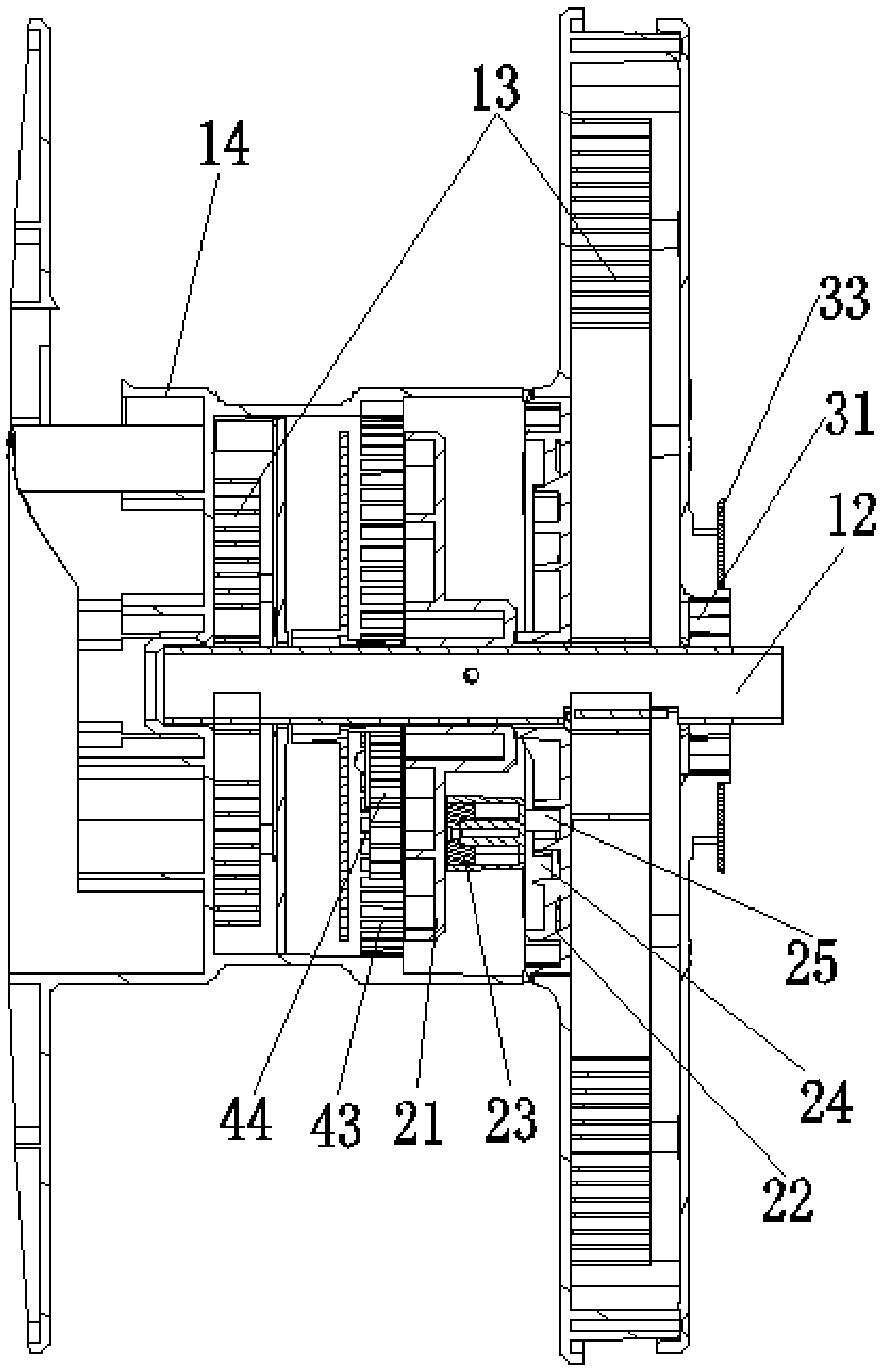

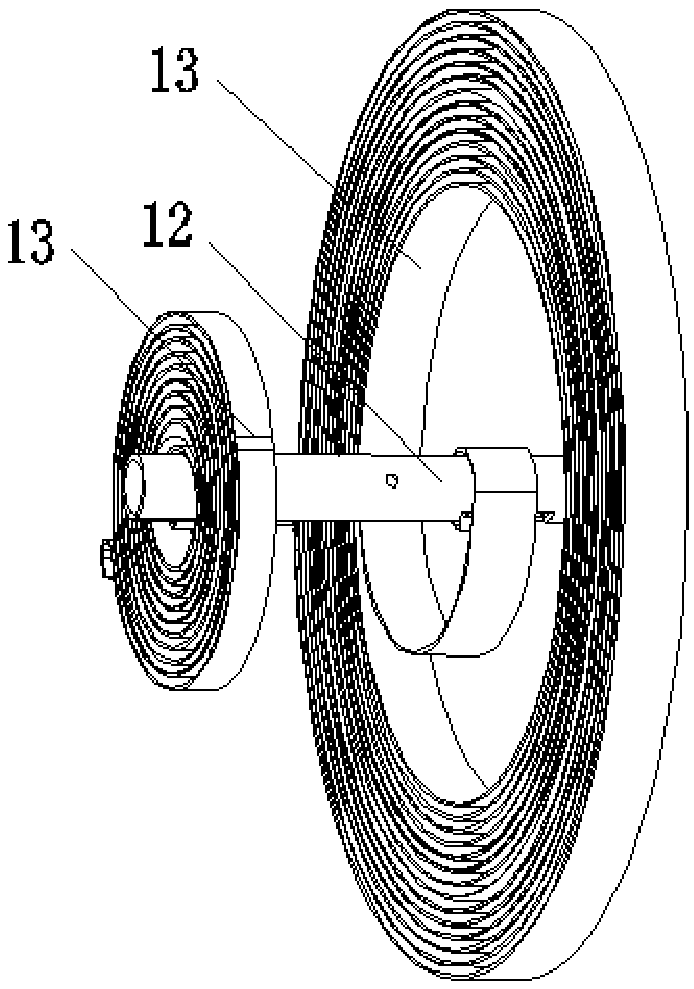

[0038] see Figure 1 to Figure 8 , a double spring winding device, including a support base 11, a support shaft 12, a coil spring 13 and a runner 14, the support shaft 12 is fixedly connected to the support base 11, the coil spring 13 is sleeved on the outside of the support shaft 12, and the coil spring The inner end of 13 is fixedly connected with the support shaft 12, and the runner 14 is sleeved on the outside of the support shaft 12 and the coil spring 13, and the runner 14 is respectively rotatably connected with the support shaft 12 and fixedly connected with the outer end of the coil spring 13 , An annular gap is formed between the support shaft 12 and the runner 14, two coil springs 13 are provided, and the two coil springs 13 are respectively arranged at different positions along the axial direction of the annular gap. By arranging the two coil springs 13 at two axial positions of the rotating wheel 14, the forces on each position of the rotating wheel 14 in the axia...

Embodiment 2

[0052] The rest are the same as in Embodiment 1, the difference is that a wire-releasing guide groove and a wire-receiving guide groove are provided on the opposite surface of the locking plate A, and the opposite surface of the locking plate B can be moved through a shaft part parallel to the support shaft. Rotate and connect a guide block.

Embodiment 3

[0054] The rest is the same as the first embodiment, except that the pay-off guide groove includes a section of the first groove bottom connected end to end, and the wire take-up guide groove includes a second groove bottom connected end to end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com