Roof color steel plate lap-joint structure and mounting method thereof

An installation method and color steel plate technology, applied in the direction of roof, roof covering, roof using flat/curved panels, etc., can solve the collapse of the overlapping part of the roof color steel plate, the installation of the broken part is not reliable enough, and the strength of the overlapping part is low. and other problems, to achieve the effect of reliable waterproof effect, simple and fast installation process, and reliable lap joint structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

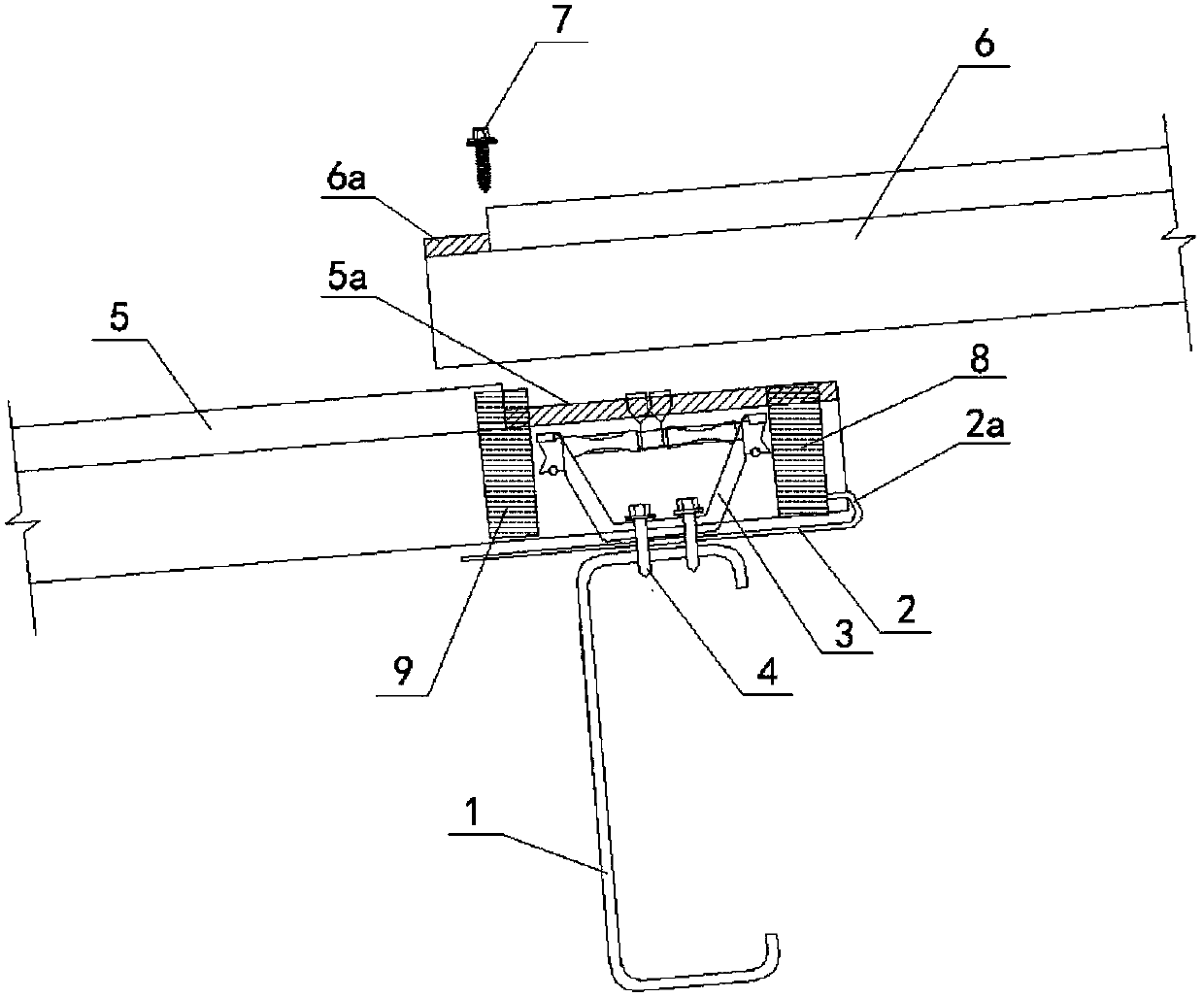

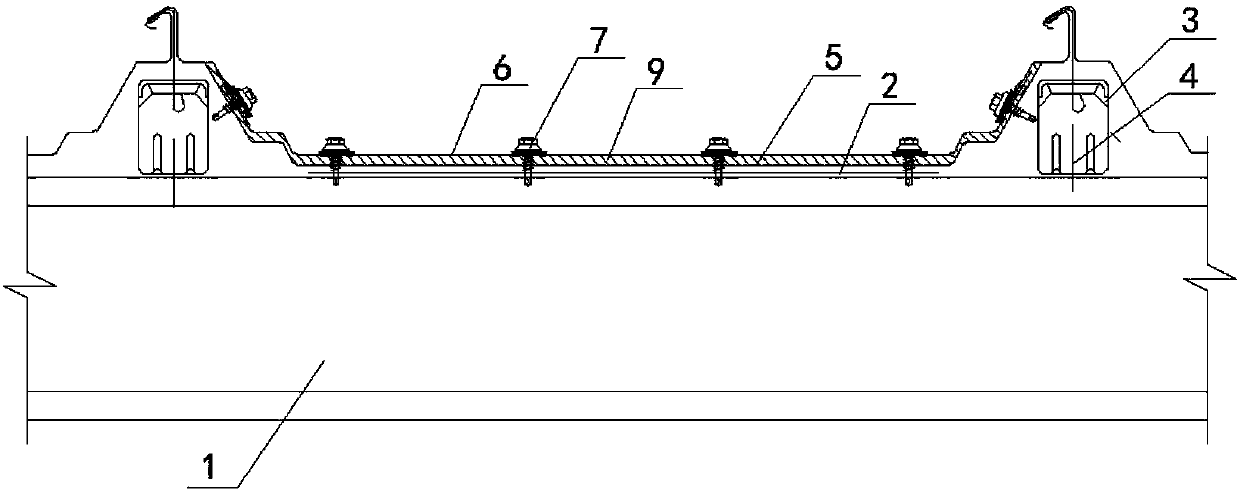

[0024] see figure 1 with figure 2 In this embodiment, the roof color steel plate lap structure includes roof purlin 1, roof lower plate 5 and roof upper plate 6, and roof lower plate 5 and roof upper plate 6 are all roof color steel plates; The board 2 , the top section of the lower roof board 5 and the bottom section of the roof upper board 6 form an overlapping section on the reinforcement board 2 .

[0025] The cross-section of the roof color steel plate is "U" shaped in the middle, one side of the crest is a male rib, and the other side is a female rib, and the adjacent roof color steel plates are interlocked by the male rib and the female rib. In this embodiment, in the overlapping section, the male and female ribs in the roof lower panel 5 and the roof upper panel 6 are respectively cut to form notches, figure 1 The figure shows that the overlapping parts of the male and female ribs of the roof lower panel 5 are cut to form the roof lower panel notch 5a, and the overl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com