Spliced micro-crystal glass plate

A glass-ceramic, splicing technology, applied in the field of building decoration materials, can solve the problems of low splicing accuracy, affect the aesthetics, slow speed, etc., and achieve the effect of improving the splicing speed and flatness, the surface is soft, and the alignment is accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

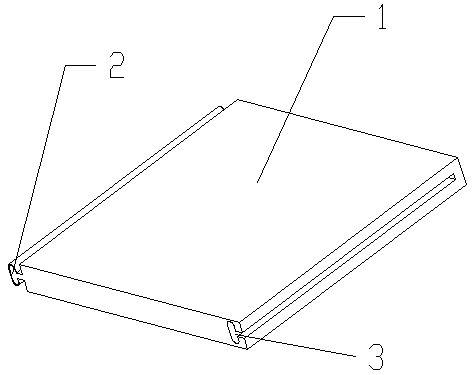

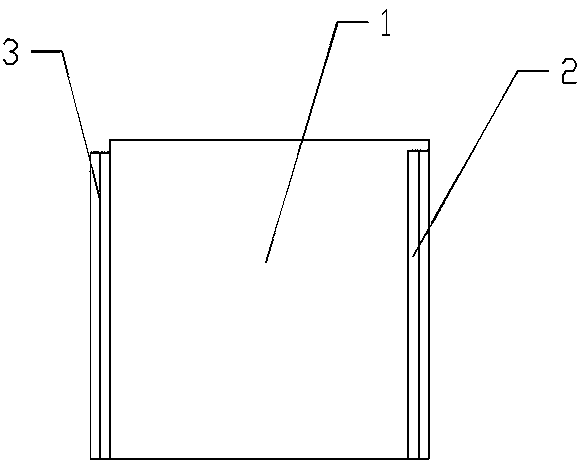

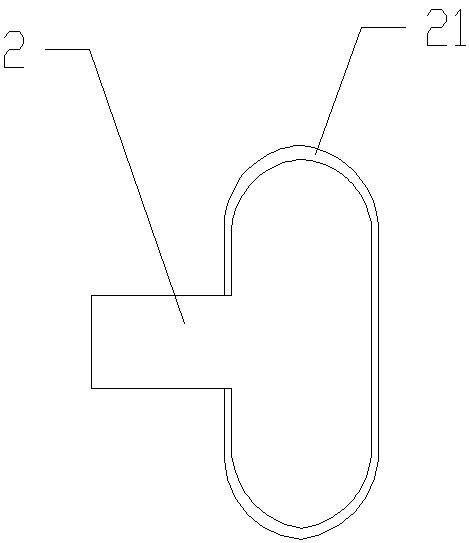

[0019] A spliced glass-ceramic plate, comprising a main body of a plate 1, a protruding strip 2 is provided on one side of the plate 1, and a groove 3 is provided on the other side, which fit together, and the outer surface of the protruding strip 2 is wrapped with silica gel The layer 21 has one end shorter than the plate 1 by 0.1 mm, and the groove 3 is closed at one end with a closed thickness of 0.3 mm.

[0020] Further, the protruding strip 2 has a horizontal T shape.

[0021] Furthermore, the thickness of the silica gel layer 21 is 0.05 mm.

Embodiment 2

[0023] A spliced glass-ceramic plate, comprising a main body of a plate 1, a protruding strip 2 is provided on one side of the plate 1, and a groove 3 is provided on the other side, which fit together, and the outer surface of the protruding strip 2 is wrapped with silica gel The layer 21 has one end shorter than the plate 1 by 0.3 mm, and the groove 3 is closed at one end with a closed thickness of 0.1 mm.

[0024] Further, the protruding strip 2 has a horizontal T shape.

[0025] Furthermore, the thickness of the silica gel layer 21 is 0.05 mm.

[0026] When the present invention is in use, only the shorter end of the protruding strip 2 of the plate 1 is inserted from the unclosed end of the groove 3 to complete the splicing, which is simple and quick.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com