Testing device for while-drilling acoustic logging instrument

A logging instrument and testing device technology, which is applied in the direction of earthwork drilling, borehole/well components, etc., can solve the problems of deviation in parameter adjustment, high construction cost, inability to perform online test of instrument measurement and control circuits, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

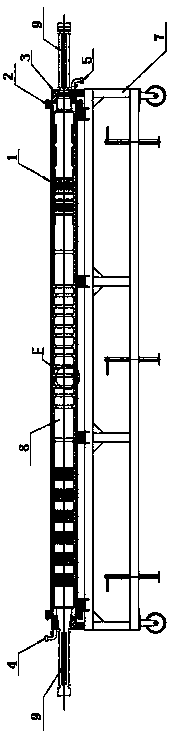

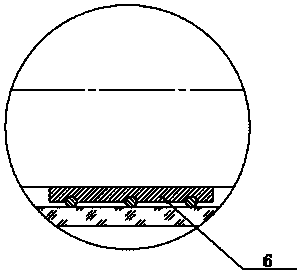

[0020] Such as figure 1 As shown, the present invention includes a shaft 1, a flange 2, a plug 3, an inlet pipe 4, an outlet pipe 5, an inner pulley bracket 6, and a shaft bracket 7. The wellbore 1 is cylindrical and made of materials with stable acoustic properties. The inner diameter is larger than the maximum outer diameter of the acoustic wave tool while drilling, which is the actual borehole size for the tool to work in the downhole. It usually includes several specifications of Φ152mm, Φ216mm, and Φ241mm. Since the acoustic wave instrument measures the sliding wave propagating along the well wall between the transmitting probe and the receiving probe, the detection depth is relatively shallow, so the wall thickness of the wellbore 1 can be thinner, but in order to make the wellbore 1 have sufficient strength, it can be appropriately thickened to greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com