B10 reliable-life evaluation method of mechanical part of vehicle engine

A technology for automotive engines and mechanical parts, which is applied in special data processing applications, instruments, electrical digital data processing, etc. The design of mechanical parts and other issues can shorten the development cycle, improve the research and development efficiency, and save the research and development cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

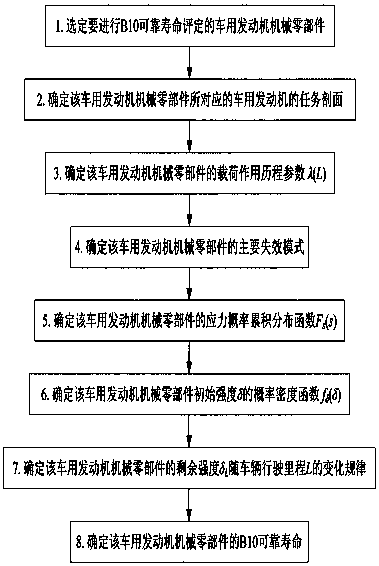

[0023] A B10 reliable life assessment method for mechanical parts of a vehicle engine, comprising the following steps:

[0024] a. Select the mechanical parts of the vehicle engine for B10 reliability life assessment. For example, the connecting rod of a vehicle engine is selected as the research object, and its B10 reliable life evaluation is carried out.

[0025] b. Determine the task profile of the vehicle engine corresponding to the vehicle engine mechanical parts. For the vehicle engine corresponding to the selected mechanical parts, combined with the use profile or working profile of the vehicle on which the vehicle engine is mounted, the task profile of the vehicle engine is determined.

[0026] c. Determine the load action history parameter λ(L) of the mechanical parts of the vehicle engine, that is, the change parameter of the number of load actions experienced by the mechanical parts with the mileage L of the vehicle. Carry out load mapping based on the task profil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com