Refractory material use performance evaluation method and system based on limit thermal load

A technology for refractory materials and evaluation methods, which is applied in special data processing applications, instruments, design optimization/simulation, etc. The effect of accurate thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

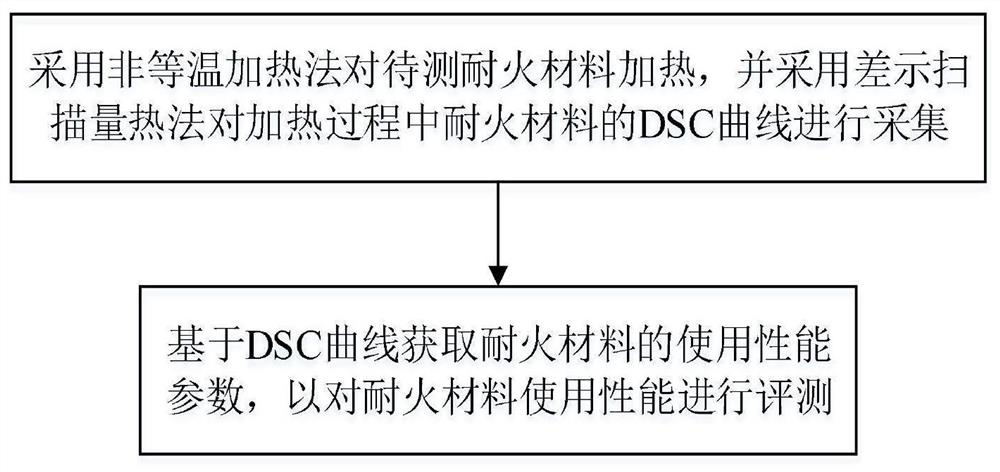

Method used

Image

Examples

Embodiment 1

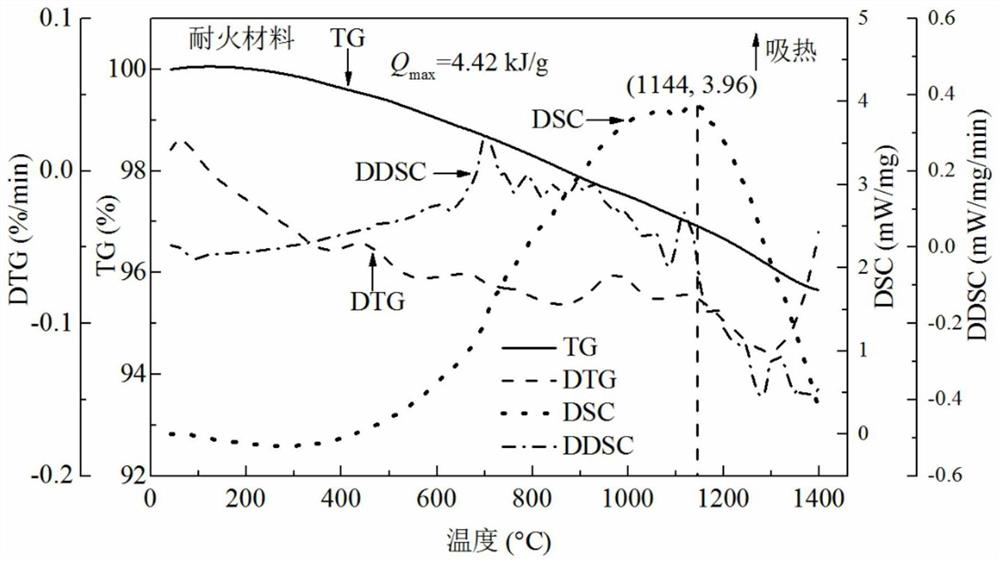

[0044] (1) Select 10mg refractory material (75wt% SiC and 25wt% Al 2 o 3 ) as the refractory material to be tested, the refractory material to be tested is heated by a non-isothermal heating method (continuous heating within 25 to 1500 °C, and the heating rate is 20 °C / min) (oxidizing atmosphere: 21% O at 100 ml / min 2 / 79%N 2 ,) to obtain a DSC curve;

[0045] (2) Obtain comprehensive parameters for evaluating the service performance of the refractory material to be tested through the DSC curve, including the limit temperature T of the refractory material max , limit heat load Q max , average heat load Instantaneous heat flow acceleration q' per unit mass refractory material and average heat flow acceleration per unit temperature difference per unit mass refractory material

[0046] The calculation process of the above parameters is as follows:

[0047] ① Obtain the corresponding temperature when the heat flow of the DSC curve reaches the maximum value, and obtain the...

Embodiment 2

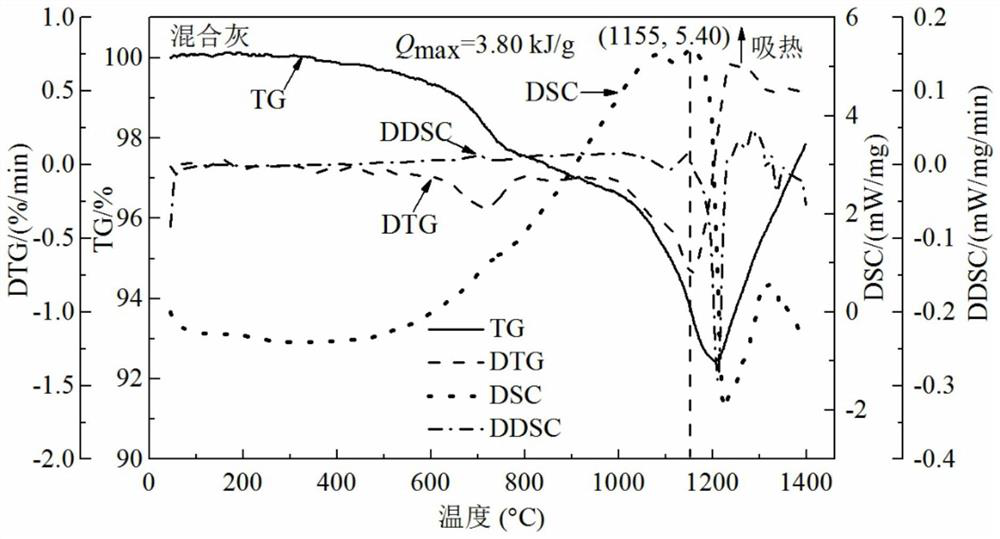

[0060] This example is roughly the same as Example 1, except that in this example, the mixed ash obtained by mixing the refractory material and coal ash with a mass ratio of 1:1 is used as the refractory material to be tested; wherein, the coal ash is selected from Hongshaquan ash , Prepared in an air atmosphere at 500°C. Ash components were measured by X-ray fluorescence spectrometry (XRF), and the results are shown in Table 2.

[0061] Table 2

[0062]

[0063] Also adopt the method in embodiment 1 to calculate, obtain a DSC curve, specifically, such as image 3 Shown is the thermal analysis diagram of the refractory material to be tested in this embodiment, and then the performance parameters of the mixed ash are obtained, as shown in Table 3.

[0064] table 3

[0065]

[0066] Comparing Table 1 in Example 1 and Table 3 of the present embodiment shows that the addition of red sand spring ash has a significant effect on the limit temperature T max The effect is sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com