Wire locking and positioning assembly structure

A technology of locking positioning and component structure, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of poor connection stability between wires and support rods, easy slipping of wires, etc., and achieve stable positioning and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

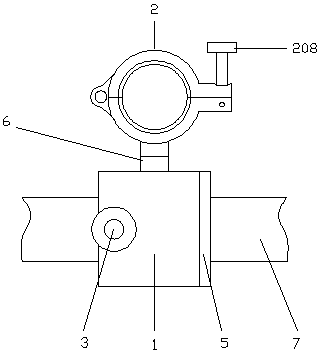

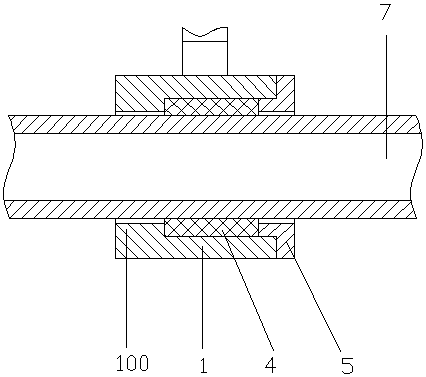

[0021] Such as figure 1 The wire locking and positioning assembly structure shown includes a sliding sleeve 1, a hoop 2 connected to the side of the sliding sleeve, and a locking mechanism 3 is provided in the sliding sleeve; figure 2 As shown, the inner center of the sliding sleeve is provided with a linear bearing 4, and the inner wall of one end of the sliding sleeve is provided with a limiting convex ring 100. The inner diameter of the limiting convex ring is larger than the inner diameter of the linear bearing and smaller than the outer diameter of the linear bearing. The other end of the sliding sleeve There is a bearing limit sleeve 5, and the threaded connection between the bearing limit sleeve and the sliding sleeve;

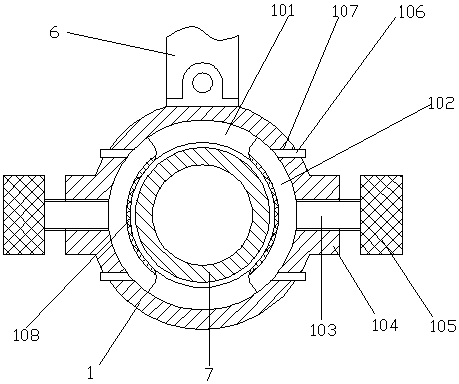

[0022] Such as image 3 As shown, the inner wall of the limiting convex ring 100 is provided with an annular groove 101, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com