gears for gear drives

A technology of gear transmission and planetary gear transmission, which is applied in gear transmission devices, transmission devices, hoisting devices, etc., and can solve problems such as limited structural space of torsion springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

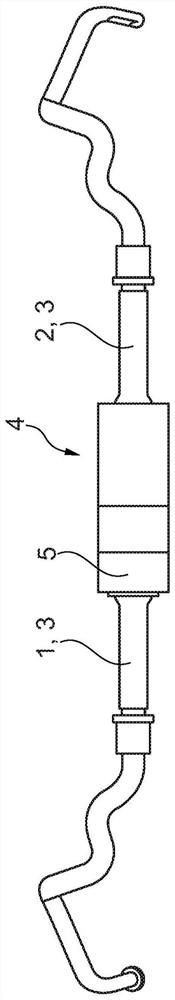

[0040] figure 1 Shown is an active roll stabilization device for a multi-train wheeled vehicle with a torsion bar 3 divided into two torsion bar parts 1 , 2 and an active actuating mechanism arranged between the two torsion bar parts 1 , 2 . device 4. This active roll stabilization device is arranged perpendicular to the longitudinal axis of the vehicle; its free end is connected to a wheel carrier, not shown in the drawing. The actuator 4 has a hollow cylindrical housing 5 in which an electric drive (not shown in the figure) and a planetary gear connected to the drive (also not shown in the figure) are accommodated. The housing 5 is connected to the torsion bar part 2 in a rotationally fixed manner. The output shaft (not shown) of the planetary gear is connected in a rotationally fixed manner to the torsion bar part 1 . When the actuator is actuated, the two torsion elements 1 , 2 rotate relative to each other and generate a torque.

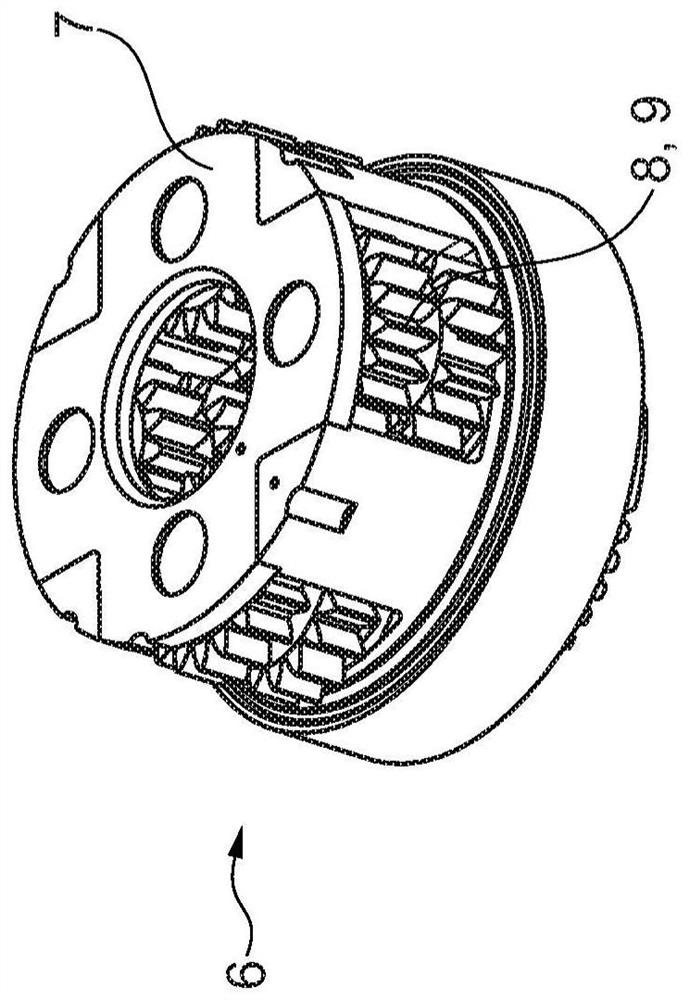

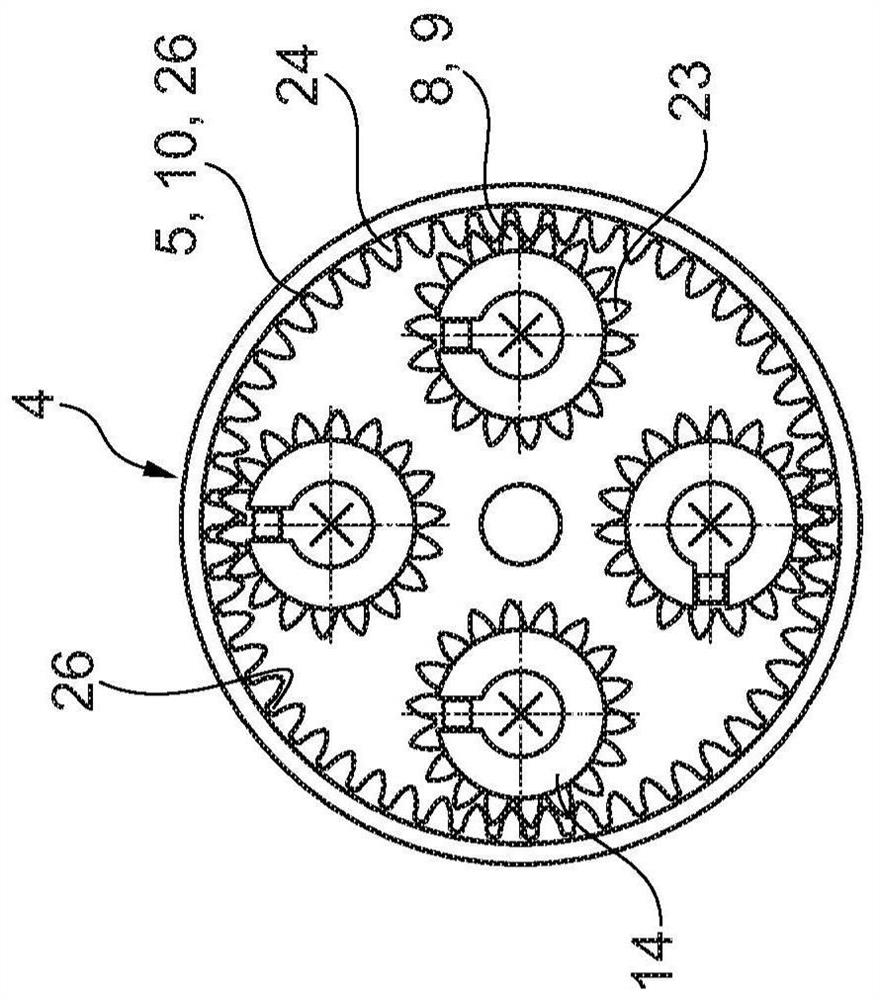

[0041] figure 2 A planetary gear st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com