Vertical and automatic indentation machine

An indentation machine and vertical technology, which is applied in the field of vertical automatic indentation machines, can solve problems such as inability to form indentation effects, and achieve the effect of obvious indentation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

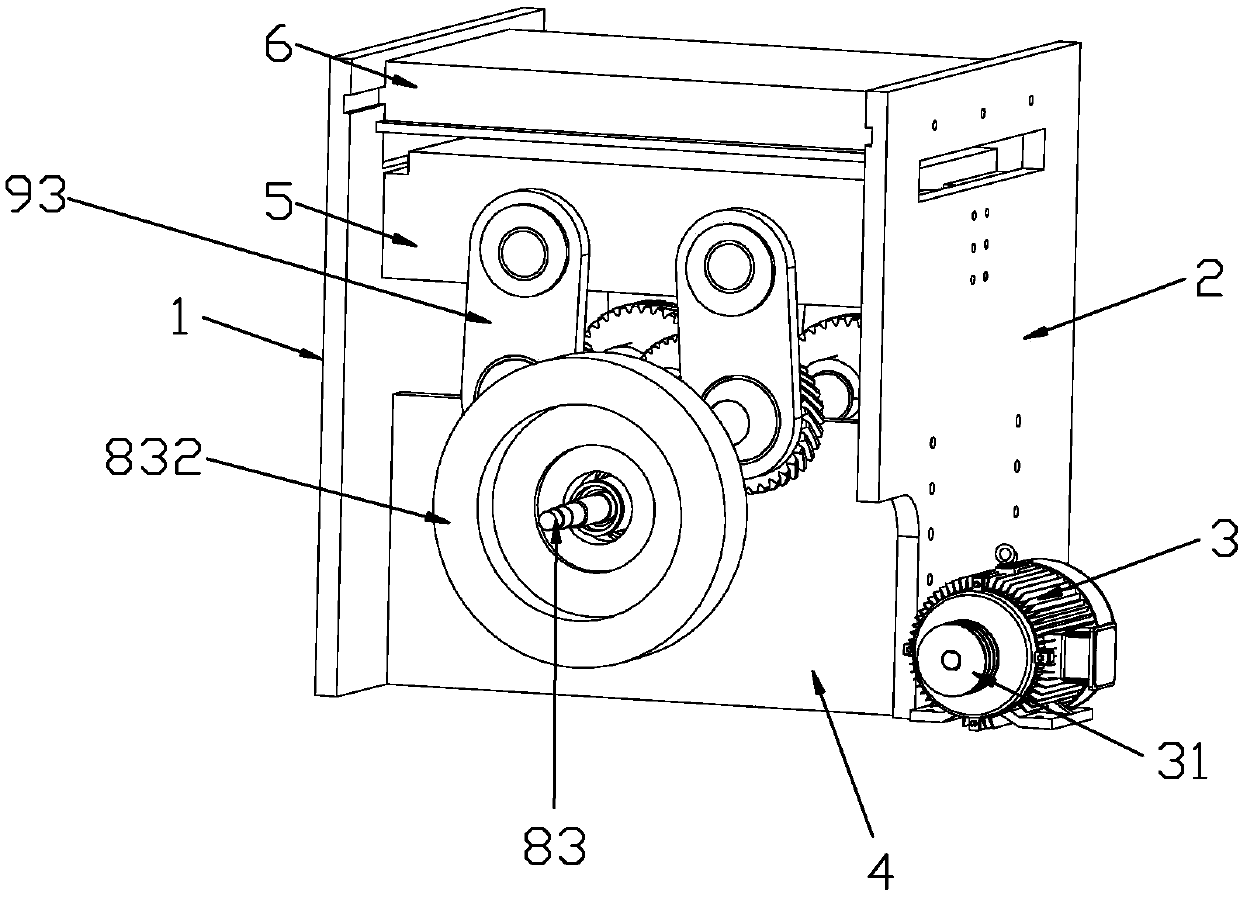

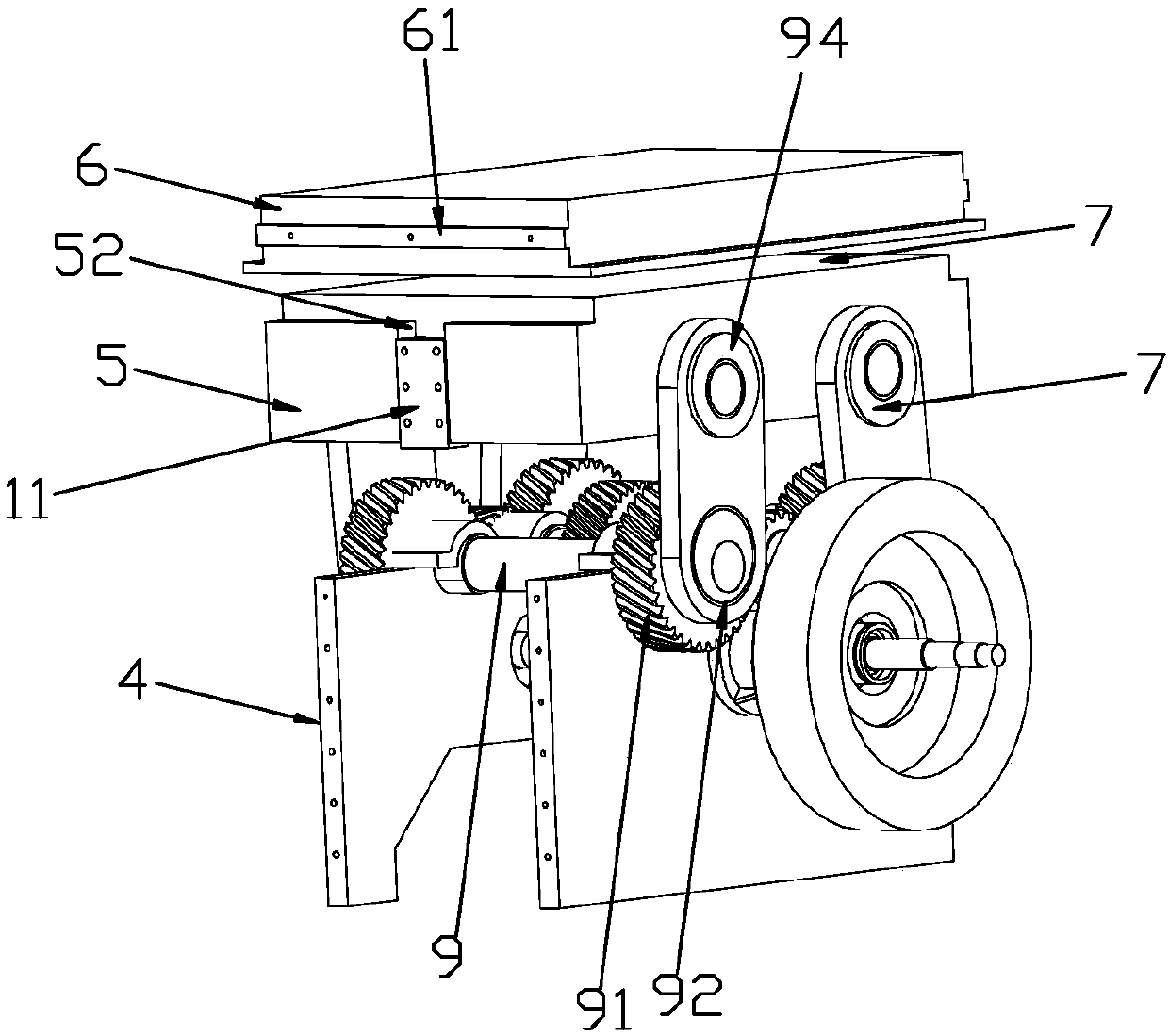

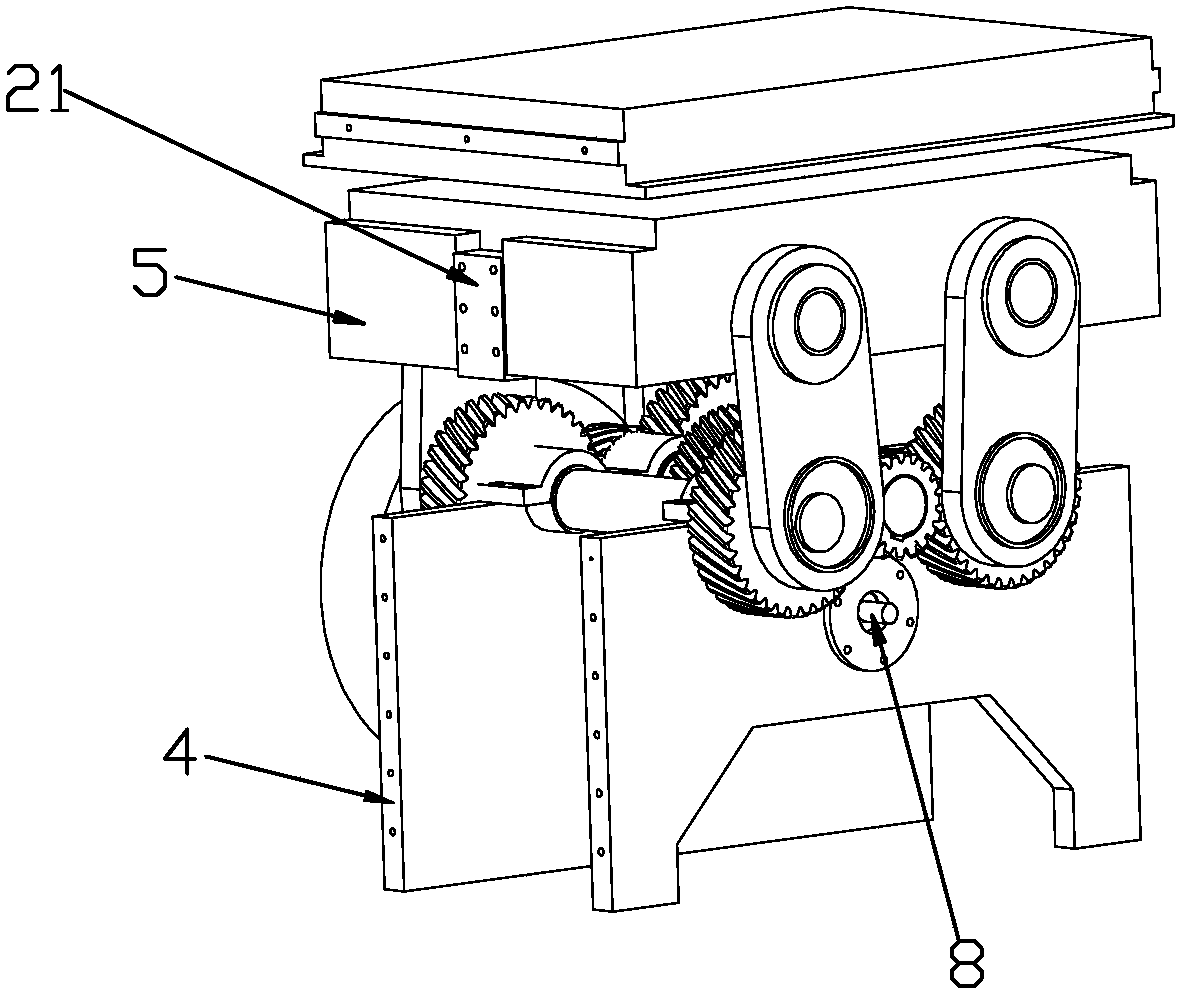

[0018] see Figure 1-Figure 4 Shown: a vertical automatic indentation machine, including a front vertical board and a rear vertical board 2 which are arranged oppositely, a driving motor 3 is connected to one side of the rear vertical board 2, and the other end of the rear vertical board 2 is relatively connected to the driving motor 3 The vertical board 4 is connected with the front vertical board 1 through the opposite vertical board 4, and the vertical board 4 is connected with the moving board 5 through the vertical indentation mechanism of vertical reciprocating motion. One end of 4 is provided with a static plate 6, and a working chamber 7 is provided between the moving plate 5 and the static plate 6. The vertical indentation mechanism includes at least two sets of connecting rod devices that are relatively established and vertically reciprocating. A first transmission shaft 8 is provided, and a first transmission gear 81 is respectively provided at both ends of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com