Lifting appliance for automatic transfer lines of automotive rear bridges

A technology of automobile rear axle and conveying line, which is applied in the field of conveying machinery, can solve the problems of low work efficiency, prone to safety accidents, poor reliability, etc., and achieve the effect of fast transfer, novel structure and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

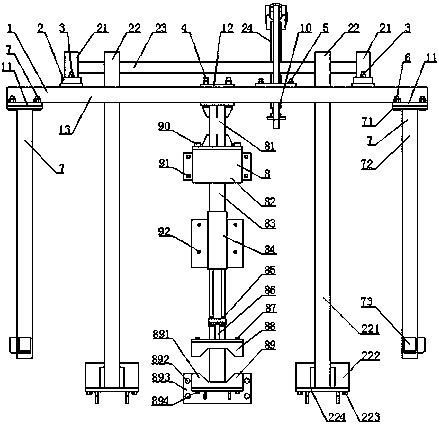

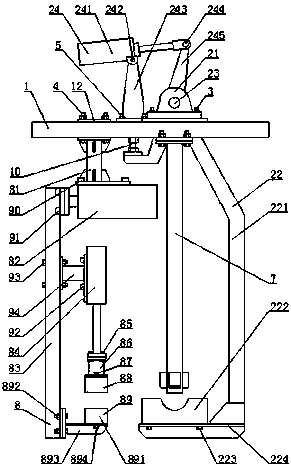

[0008] see Figure 1 to Figure 2 , the present invention includes a frame 1, a swing hanging leg rotating device 2, a jaw assembly 8, two guide rods 7, a limit screw 10, several bolts one 3, several bolts two 4, several bolts three 5 and several Bolt four 6, described framework 1 comprises connecting plate II12, frame body 13 and two connecting plates I11, described two connecting plates I11 are symmetrically welded on the left and right sides of frame body 13 bottom surfaces, described connecting plate II12 is welded on In the middle part above the frame body 13, the swinging leg rotating device 2 includes a rotating shaft 23, a swinging leg driving assembly 24, two bearing housings 21 and two swinging hanging legs 22, and the swinging leg driving assembly 24 includes a swinging cylinder 241, rotating shaft I242, swing cylinder support 243, rotating shaft II244 and connecting rod 245, each of the swing hanging legs 22 includes a swing rod 221, a swing hanging claw 222, a swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com