The operation method of the car-carrying slab-type three-dimensional garage and the longitudinally rearranged three-dimensional garage

A technology of a three-dimensional garage and an operation method, which is applied in the direction of buildings, building types, buildings, etc. where cars are parked, and can solve the problems of unusable ample space and waste of space, so as to save cost investment, reduce component equipment, and increase car storage capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

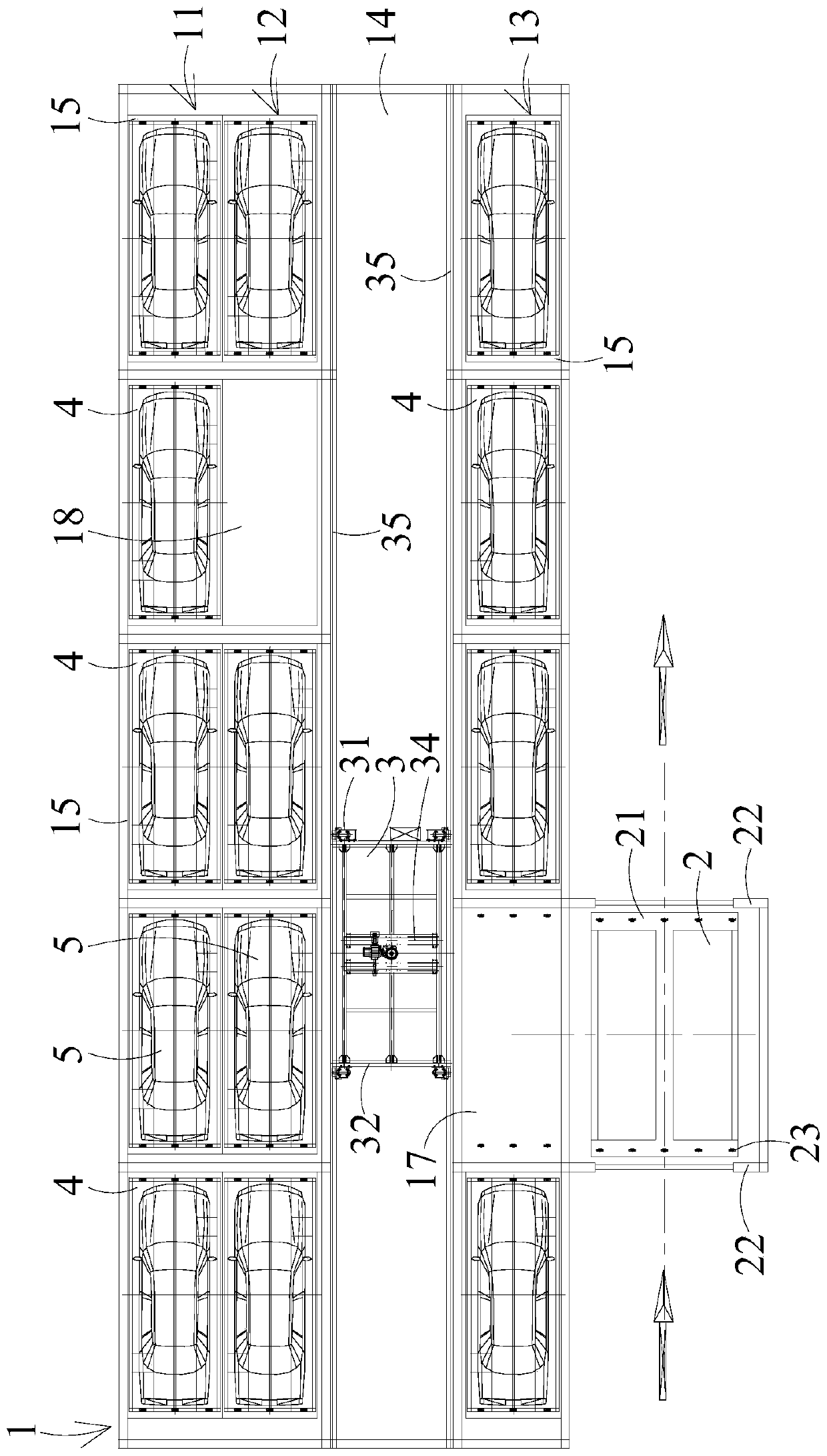

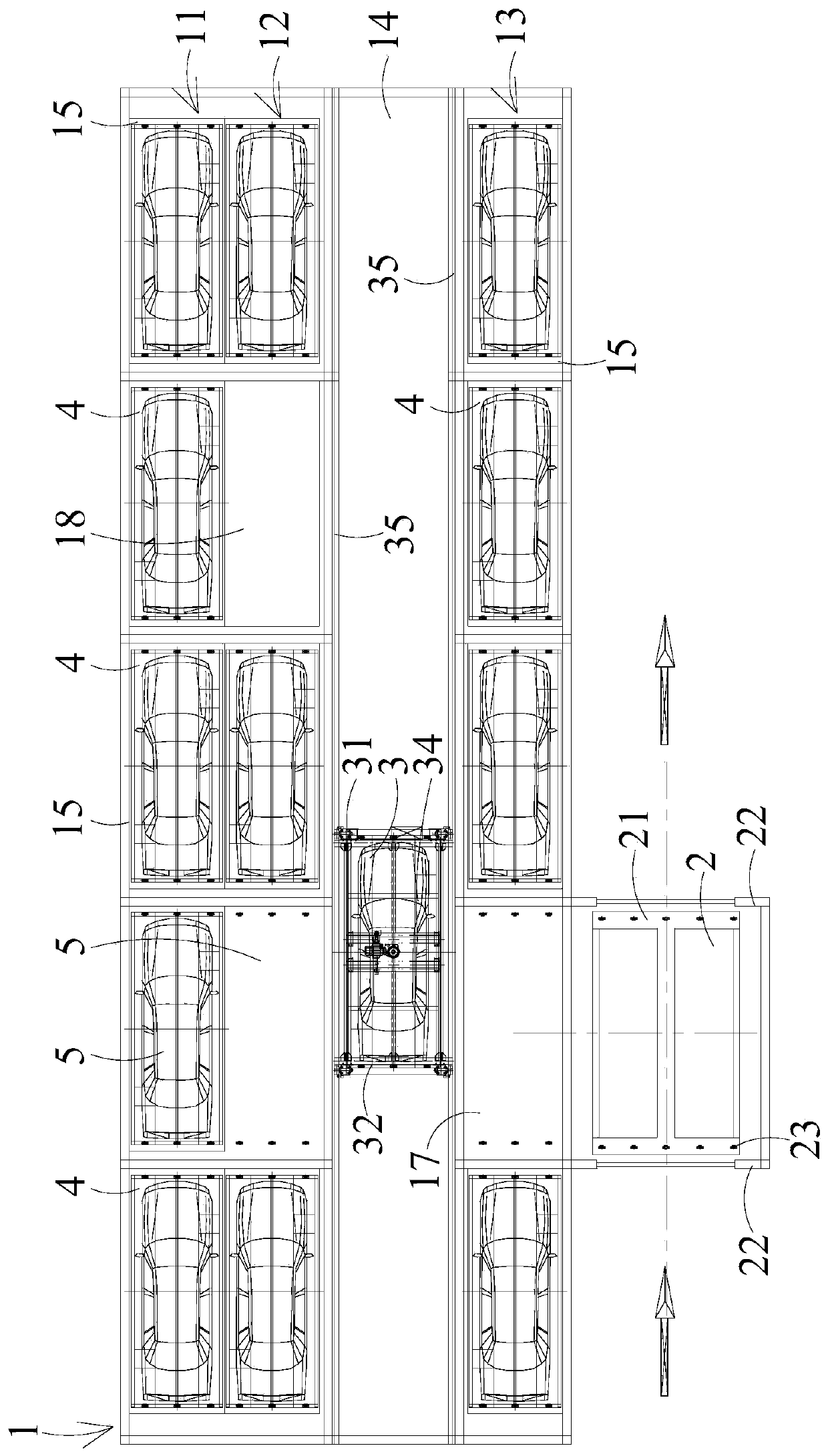

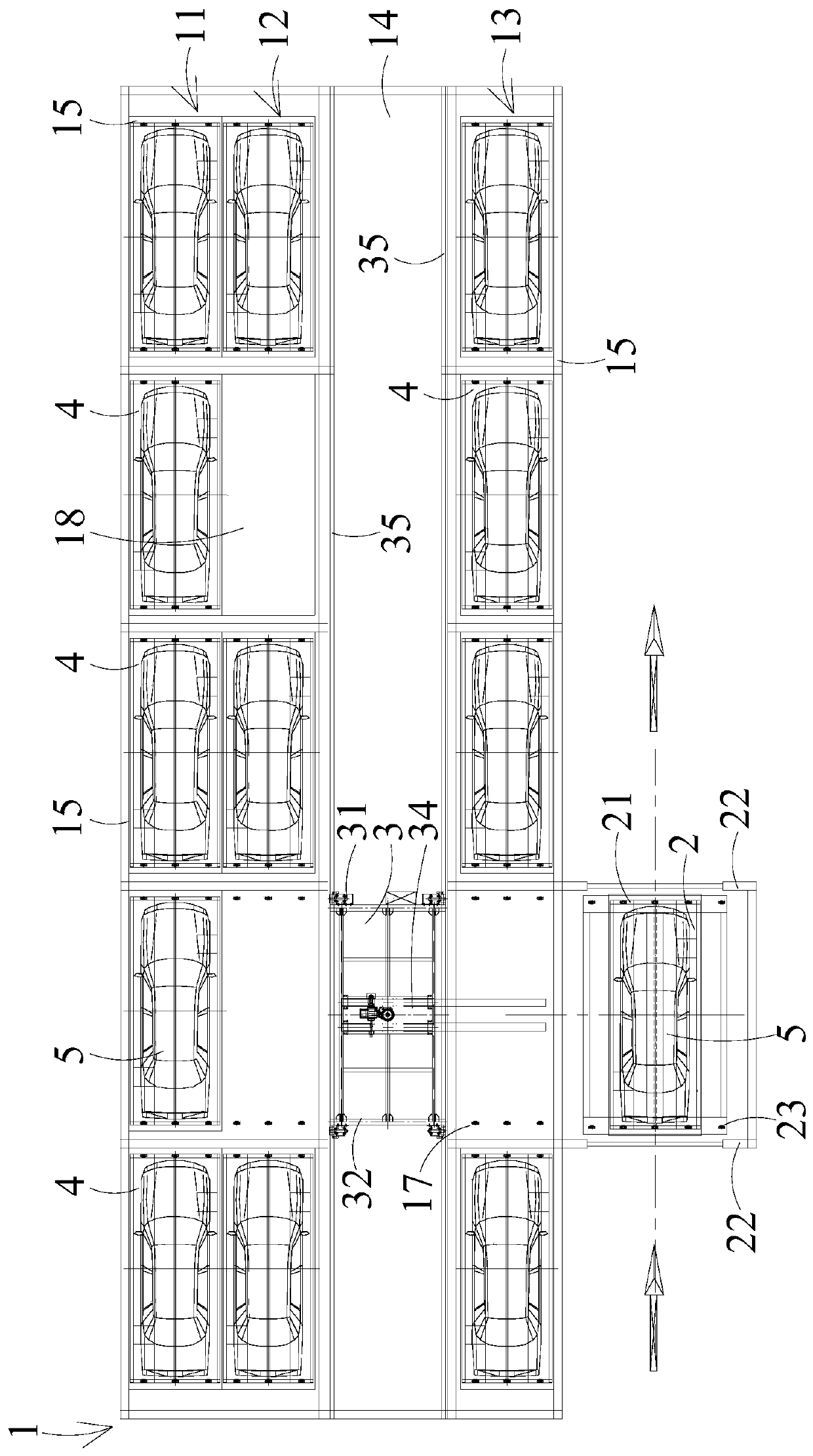

[0054] According to an exemplary embodiment of the present invention, such as Figure 6 to Figure 8 As shown, the extraction mechanism 34 mainly includes a power device 341 , a transmission mechanism 342 and a multi-stage telescopic rod 343 . The power device 341 may include a motor and a reducer, and the power device 341 can drive the multi-stage telescopic rod 343 through the transmission mechanism 342 to perform telescopic movements. In this embodiment, there are two sets of multi-stage telescopic rods 343 side by side. The transmission mechanism 342 is connected to two multi-stage telescopic rods 343 in the middle. Drive two multi-stage telescopic rods 343 to extend or retract. The transmission mechanism 342 can be provided with a coupling between the two multi-stage telescopic rods 343 to ensure transmission safety.

[0055] The end of the multi-stage telescopic rod 343 can also optionally be provided with a connecting piece (not shown), which can be connected with each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com