Combined type buckle arrestor for submarine fiber-reinforced composite flexible pipe

A composite flexible, fiber-reinforced technology, applied in pipeline damage/abrasion prevention, pipeline protection, pipes/pipe joints/fittings, etc., can solve problems such as poor structural reliability and low buckling efficiency, and achieve wear and corrosion prevention and reinforcement The effect of buckling resistance and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other.

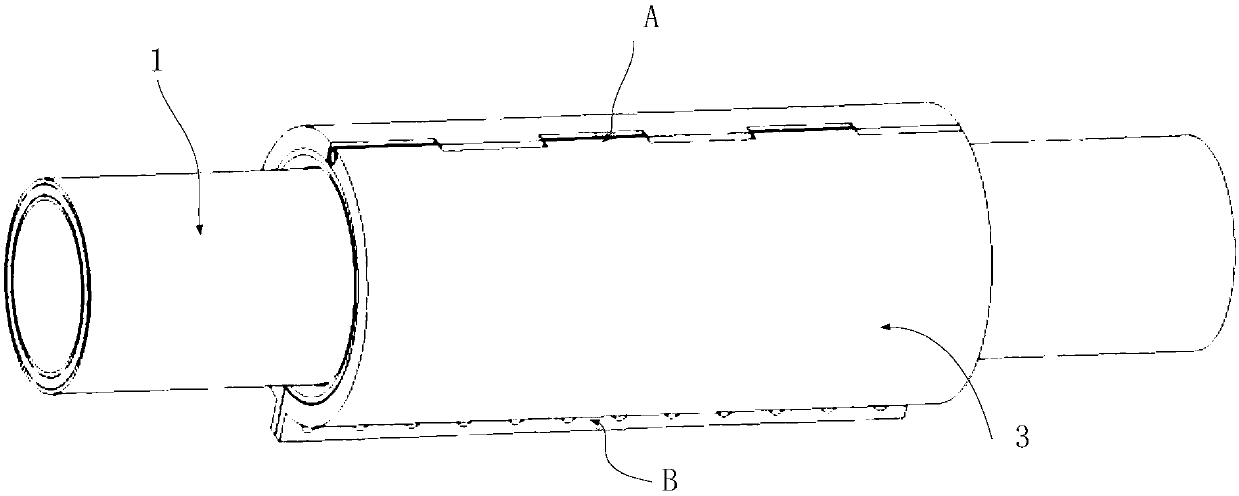

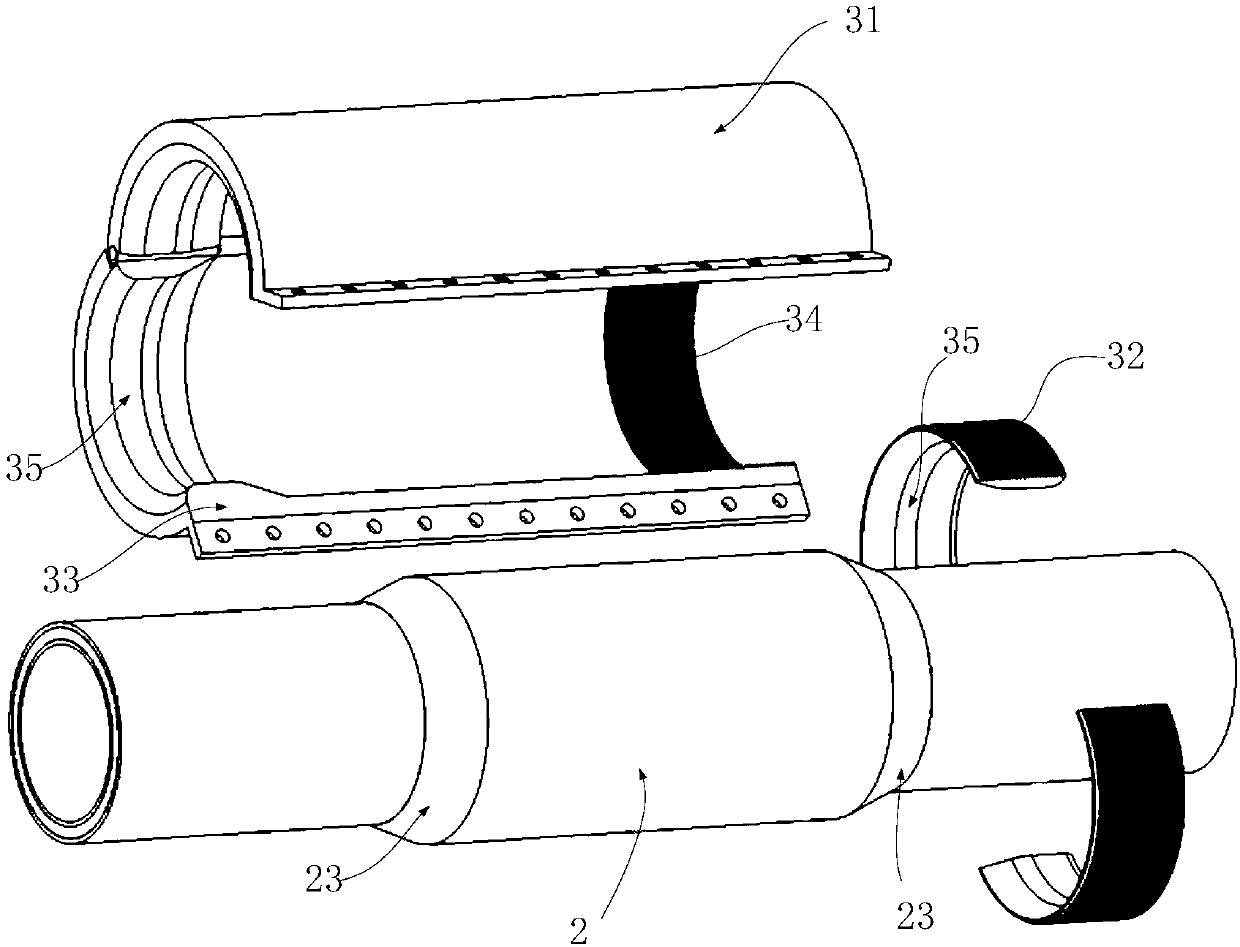

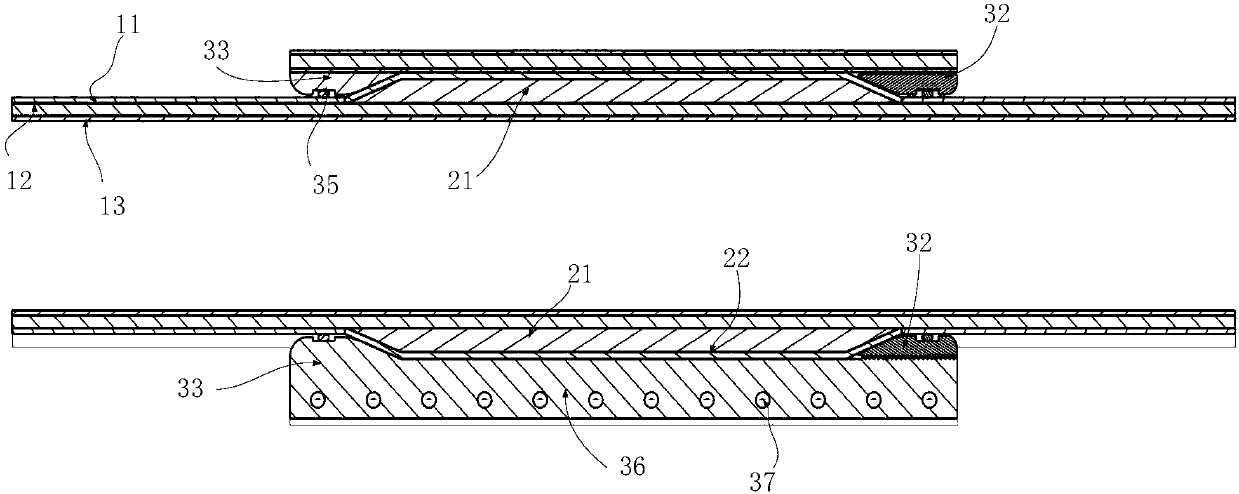

[0028] This embodiment discloses a combined buckle arrester for a submarine fiber-reinforced composite flexible pipe. For the convenience of description, the flexible pipe is referred to as a composite pipe for short below. figure 2 and image 3 , the composite pipe 1 includes an outer protective layer 11, a reinforcing layer 12 and an inner lining layer 13 from the outside to the inside, and the combined buckle arrester includes a fiber-reinforced inner collar 2 and a metal outer collar 3, combined with image 3 As shown, the fiber-reinforced inner collar 2 includes a fiber-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com