Universal fiber expanding connector and production process thereof

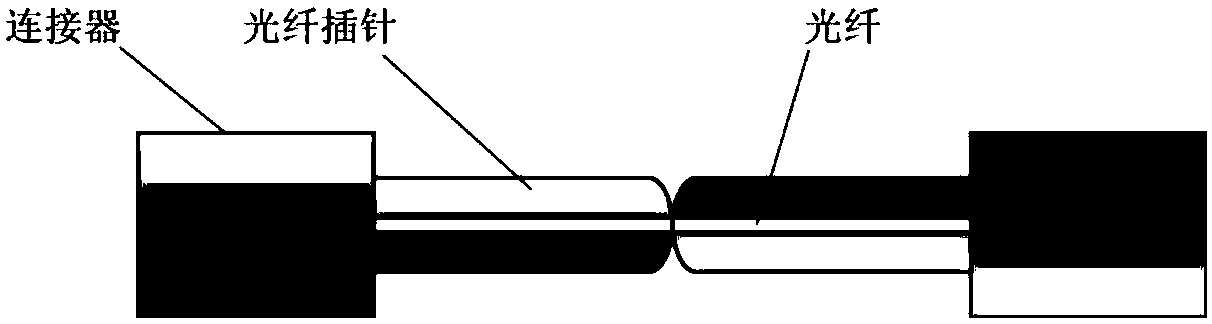

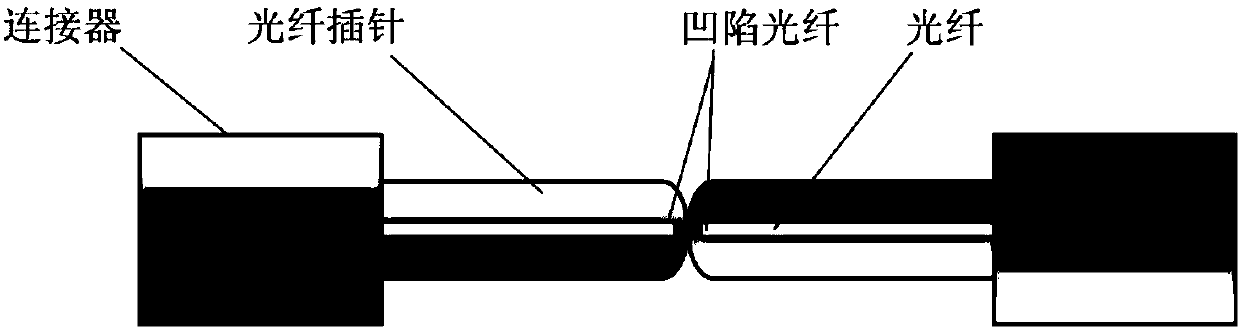

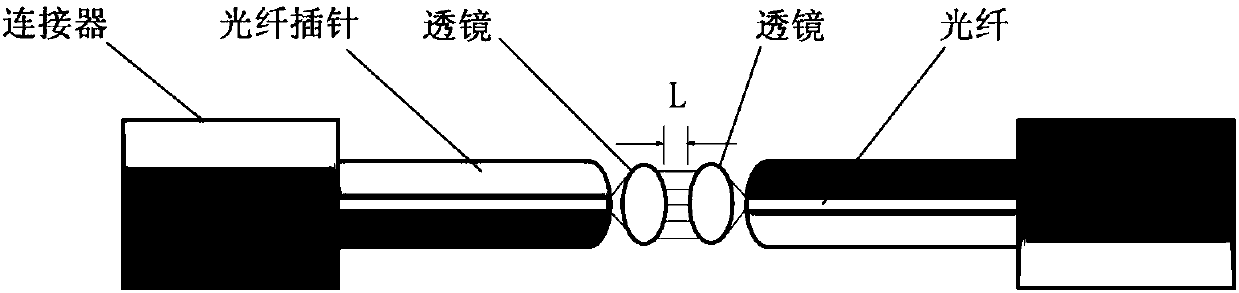

A preparation process and connector technology, which is applied in light guides, optics, instruments, etc., can solve the problems of difficult installation, cumbersome procedures, and high production costs, and achieve the effect of reducing processing costs and simple manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0037] Such as Figures 4 to 6 As shown, the present invention provides a general-purpose optical fiber beam expander connector, including a common connector spare part 1, a metal tail handle 2, a stepped ceramic ferrule 3, a sleeve-type optical fiber lens 4; the ceramic ferrule 3 The high stepped end is pressed into one end of the metal tail handle 2 to form an independent optical fiber contact; the low stepped end of the ceramic ferrule 3 is covered with a sleeve-type optical fiber lens 4; the bare optical fiber is inserted into the ceramic ferrule 3, and the optical fiber and the ceramic The ferrule 3 is connected as a whole; transparent UV glue is coated around the ceramic ferrule 3, and transparent UV glue is also coated on the end face of the optical fiber; the end face of the optical fiber of the ceramic ferrule 3 is in close contact with the convex le...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap