Screening unit in paddy rice abortive grain clearing device

A technology for removing device and grains, which is applied in the direction of separating solids from solids by air flow, filtering, solid separation, etc. It can solve the problems that small stones cannot be removed, and achieves simple structure, convenient use, and good use effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

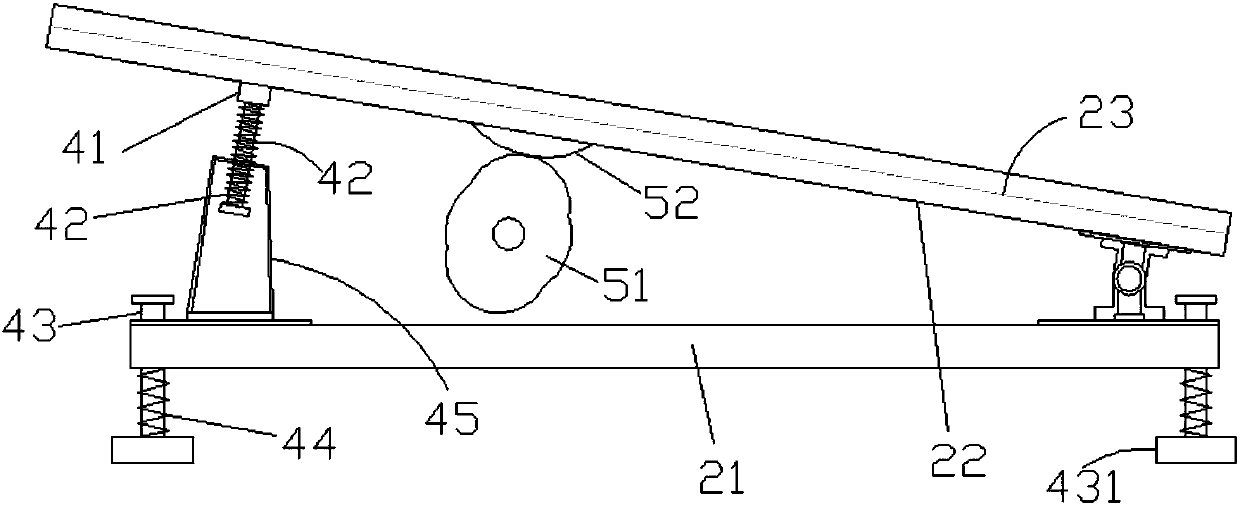

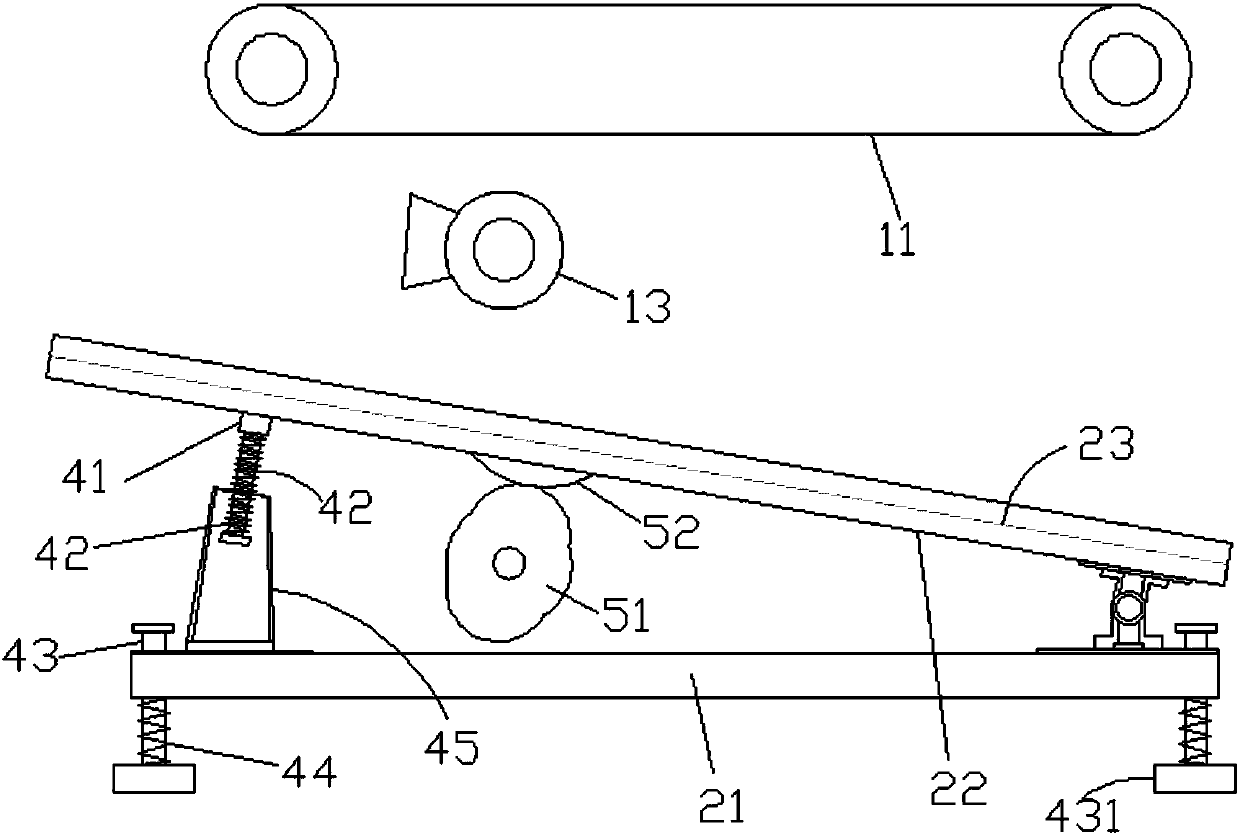

[0012] Such as figure 1 Shown, the sieving unit in a kind of rice grain removal device of the present invention comprises base 21, sieve rack 22, screen cloth 23, first guide rod 41, first spring 42, second guide rod 43, second spring 44. The support frame 45, the cam 51, the arc block 52 and the drive motor, the screen frame 22 is obliquely arranged above the base 21, and the bottom end of the screen frame 22 is hinged with the base 21, and the top end is fixedly connected with the first guide rod 41 , the first guide rod 41 is plugged into the support frame 45 , and the support frame 45 is fixed on the base 21 . The two first springs 42 are sleeved on the first guide rod 41, and the two first springs 42 are located on the upper and lower sides of the support frame 45, and the two ends of the first spring 42 at the upper end are in contact with the screen frame 22 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap