Efficiency improving and cost reducing method for pipe end expansion and special expansion mold

A mold and pipe end technology, which is applied in the field of seamless steel pipe end sizing, can solve the problems of many specifications of pipe end sizing machine expansion molds, easy damage of clamps, frequent replacement, etc., to achieve outstanding substantive features and production efficiency and the effect of cost improvement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

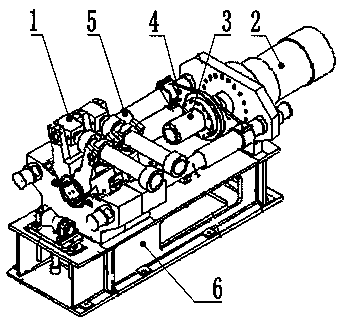

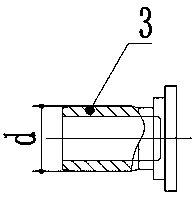

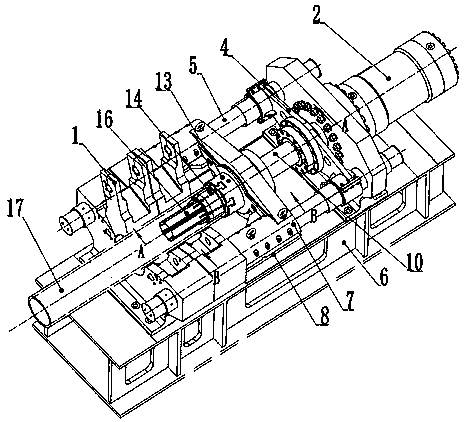

[0025] Example 1, see image 3 , 4 , 5, 6, taking the tapered push rod of the special expanding die with 6 slopes as an example;

[0026] Select a suitable supporting flange 13, install the shaft sleeve 12 in the inner hole of the supporting flange 13, install the connecting rod 10 in the shaft sleeve 12, and install the connecting rod 10 in the inner shaft of the shaft sleeve 12 installed in the center hole of the supporting flange 13 The right end of the connecting rod 10 is connected to the sliding seat 4, and the left end is connected to the tapered push rod 11 through threads; the tapered push rod 11 is provided with 6 inclined surfaces evenly distributed, and one is installed on each inclined surface to cooperate with it. The fan-shaped mold block 14, the corresponding slope of the fan-shaped mold block 14 keeps in contact with the slope of the tapered push rod 11 by the guide key 15, and the right end surface of the fan-shaped mold block 14 is connected with the T-shap...

Embodiment 2

[0033] Embodiment 2, referring to 7, is the same as embodiment 1, taking the tapered push rod of the special expanding die with 5 slopes as an example; the tapered push rod 11 of the expanding die has 5 slopes, and one is installed on each slope Sector mold block 14.

[0034] For the supporting special expansion die of the above-mentioned embodiment 2, the inner diameter of the expansion steel pipe is φ230-φ330mm; within this range, two kinds of expansion die combinations of specifications are set up, and 5 kinds of sector shapes are equipped with a difference of 20mm in nominal external diameter. Mold block group; when changing specifications, only the fan-shaped mold block 14 can be replaced.

Embodiment 3

[0035] Example 3, see Figure 8 , with embodiment 1, take the tapered push rod of special-purpose expanding die to have 4 slopes as example;

[0036] The matching mold of the above-mentioned embodiment 3 has an inner diameter of the expanded diameter steel pipe of φ140-φ230mm; within this range, 3 kinds of specifications of the expanded diameter mold combination are set; when changing the specifications, only the fan-shaped mold block 14 can be replaced.

[0037] The invention discloses a method for increasing the efficiency and reducing the cost of pipe end diameter expansion and a special diameter expansion mold. According to the inner diameter of the steel pipe, a suitable diameter expansion mold combination and a fan-shaped mold block group with matching sizes are selected, and they are installed on the supporting and fixing device. , to form a complete supporting mold for expanding diameter, and then install the supporting mold on the pipe end sizing machine, connect the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com