Input material and casting method using the same

A technology of casting slabs and continuous casting mold flux, which is applied in the field of casting materials and using them, can solve the problems of difficult to increase the number of continuous castings, difficult to ensure the quality of cast slabs, and unfavorable to reduce vertical cracks in high aluminum steel, etc. Achieve the effect of improving quality and productivity and preventing denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. However, the present invention is not limited to the embodiments disclosed below, but can be realized in various forms. The embodiments of the present invention are provided only to complete the disclosure of the present invention and fully inform the scope of the invention to those skilled in the art to which the present invention pertains. In order to illustrate the embodiments of the present invention, the drawings may be enlarged, and the same reference numerals in the drawings refer to the same structural elements.

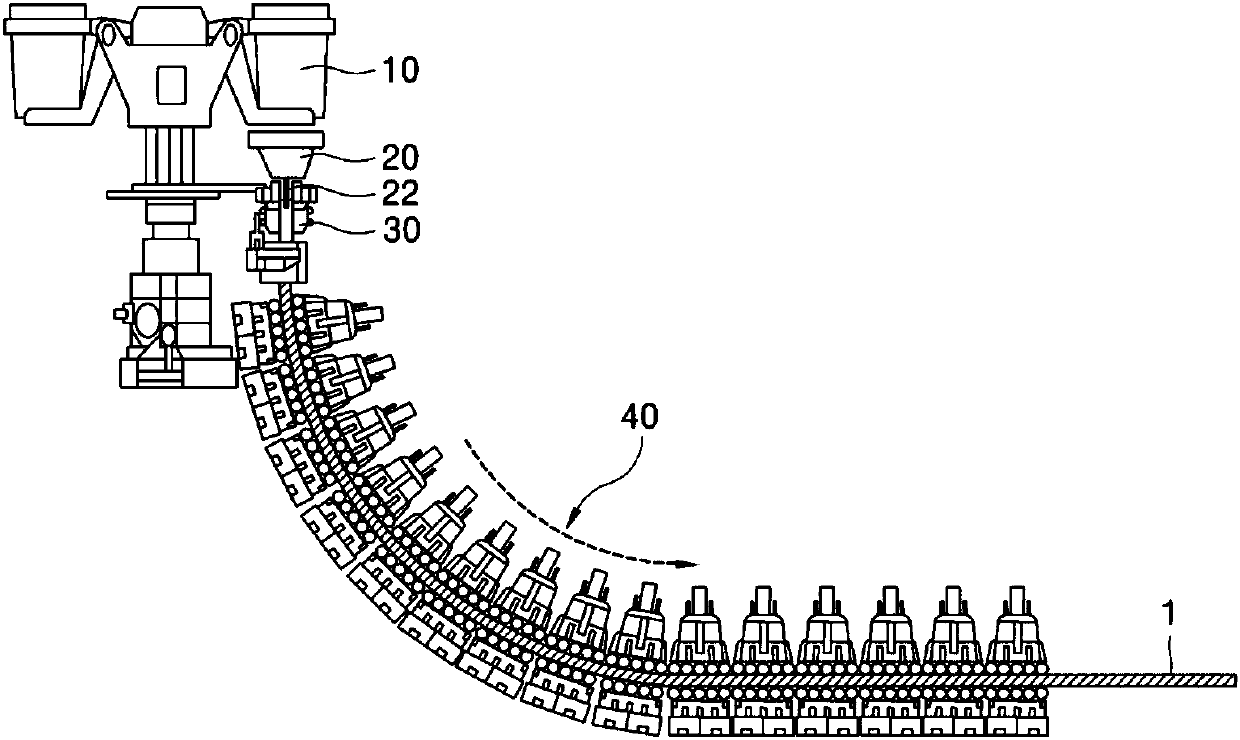

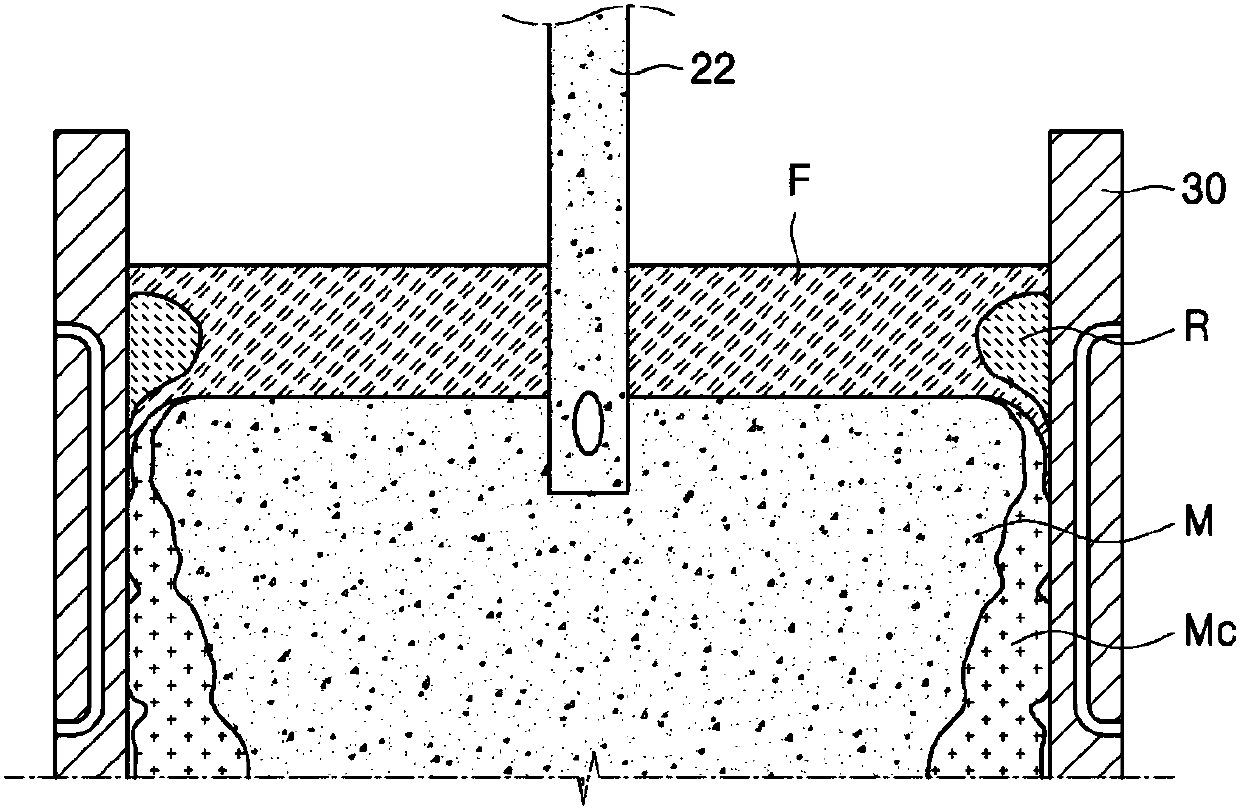

[0052] figure 1 It is a schematic diagram of casting equipment applicable to the embodiment of the present invention.

[0053] For example, casting equipment is a continuous casting equipment that receives molten steel refined in steelmaking equipment to make slabs, such as figure 1 As shown, the above-mentioned continuous casting equipment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com