Special outer water cutting assembly machine integrating flexible assembly of adhesive tape and assembly of end cover

A technology of external water cutting and strip flexibility, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of excessive pull-in force, affecting the production process of automobile external water cutting, and low production efficiency, so as to ensure quality and realize Real operability and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

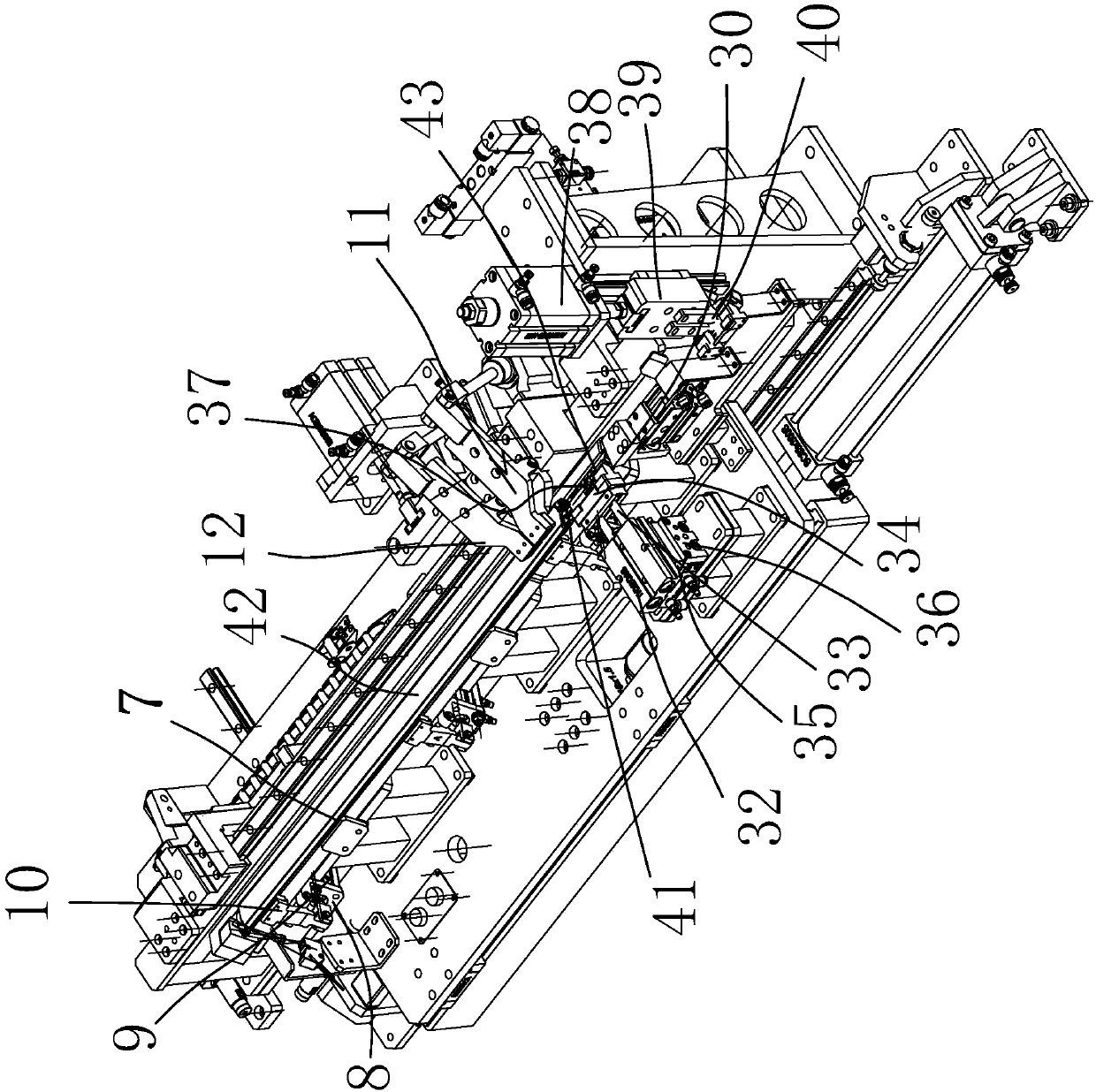

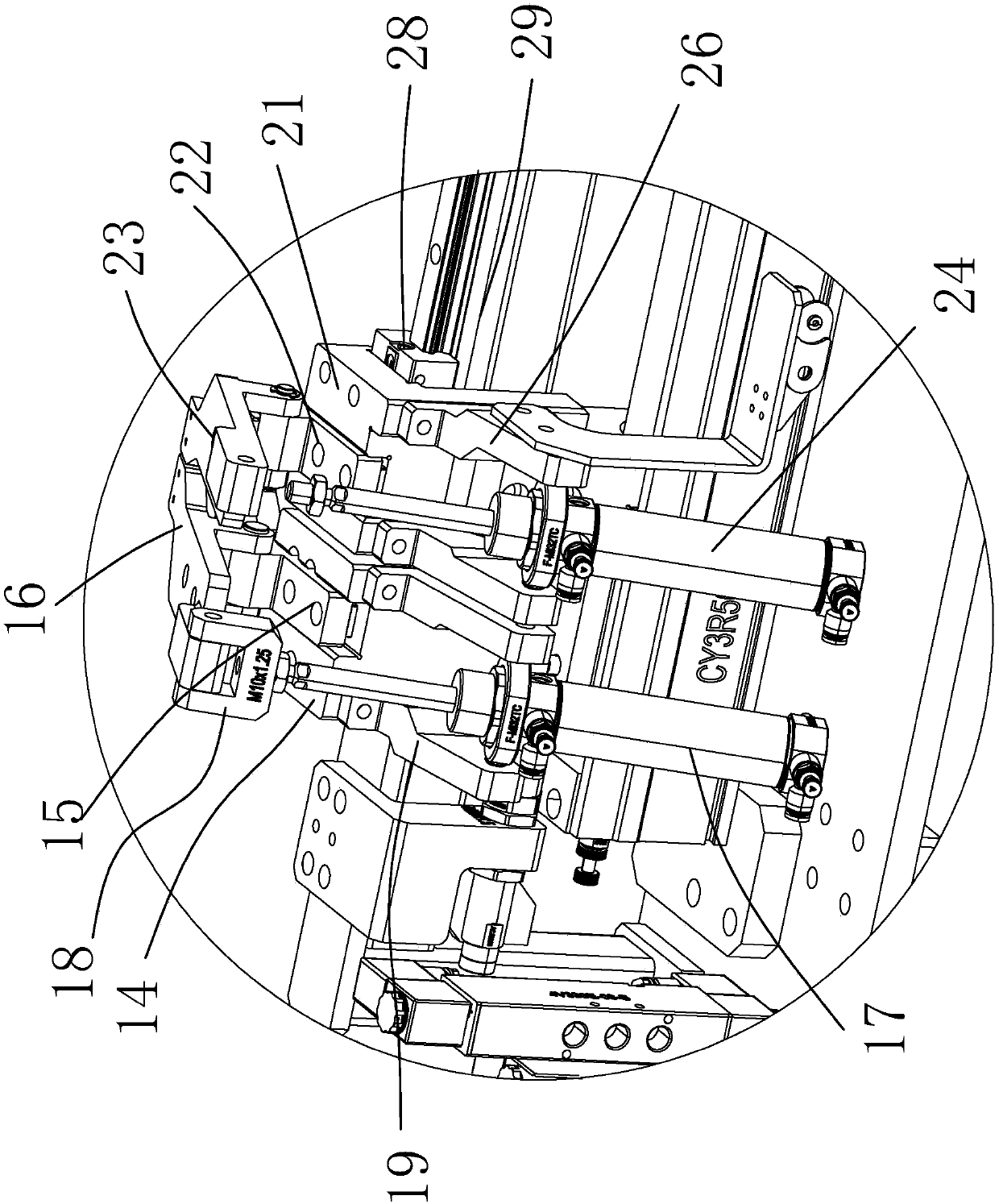

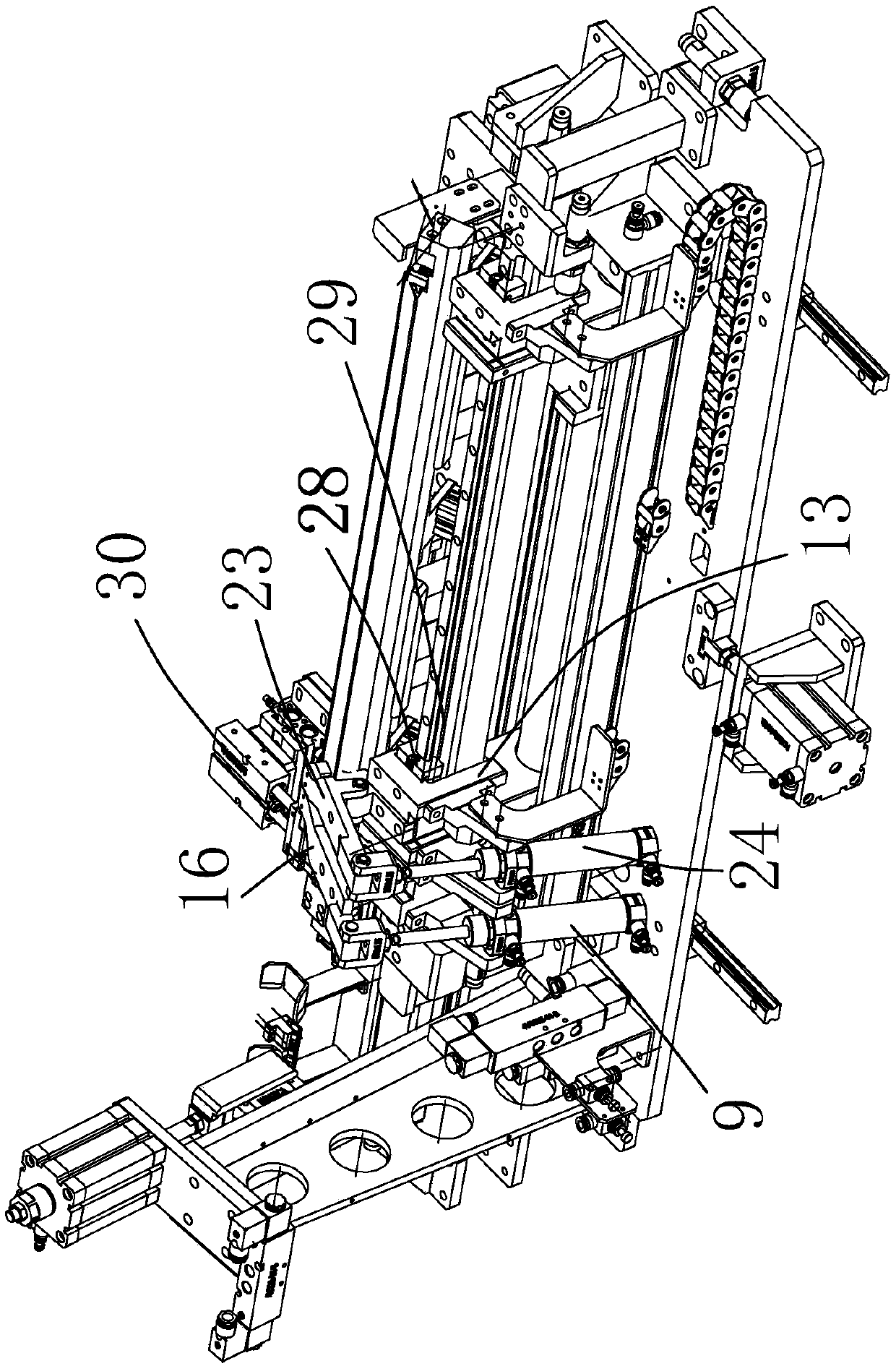

[0026] In the figure, the first main fixing plate 1; the water cutting fixing component 2; the second main fixing plate 3; the rubber strip clamping assembly component 4; the end cover assembly component 5; the riveting component 6; Seat 8; fixed cylinder 9; rotating pressure block 10; fixed clamping module 11; moving clamping module 12; rubber strip driving module 13; Clamping cylinder 17; fixed jaw joint 18; fixed rotating support seat 19; rubber strip clamping part 20; moving jaw mounting block 21; moving down jaw 22; moving up jaw 23; Gripper joint 25; moving and rotating support seat 26; rubber strip positioning part 27; transverse slider 28; sliding platform 29; end cover side positioning pull module 30; end cover en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com