Anti-dust device for plate drilling equipment

A technology of punching equipment and dust-proof device, which is applied in the direction of wood processing equipment, bark area/debris/dust/waste removal, manufacturing tools, etc. It can solve the problem of affecting the air quality of the workshop, affecting the health of workers, and poor working environment, etc. problem, to achieve the effect of preventing sawdust from splashing, facilitating normal implementation, and facilitating adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

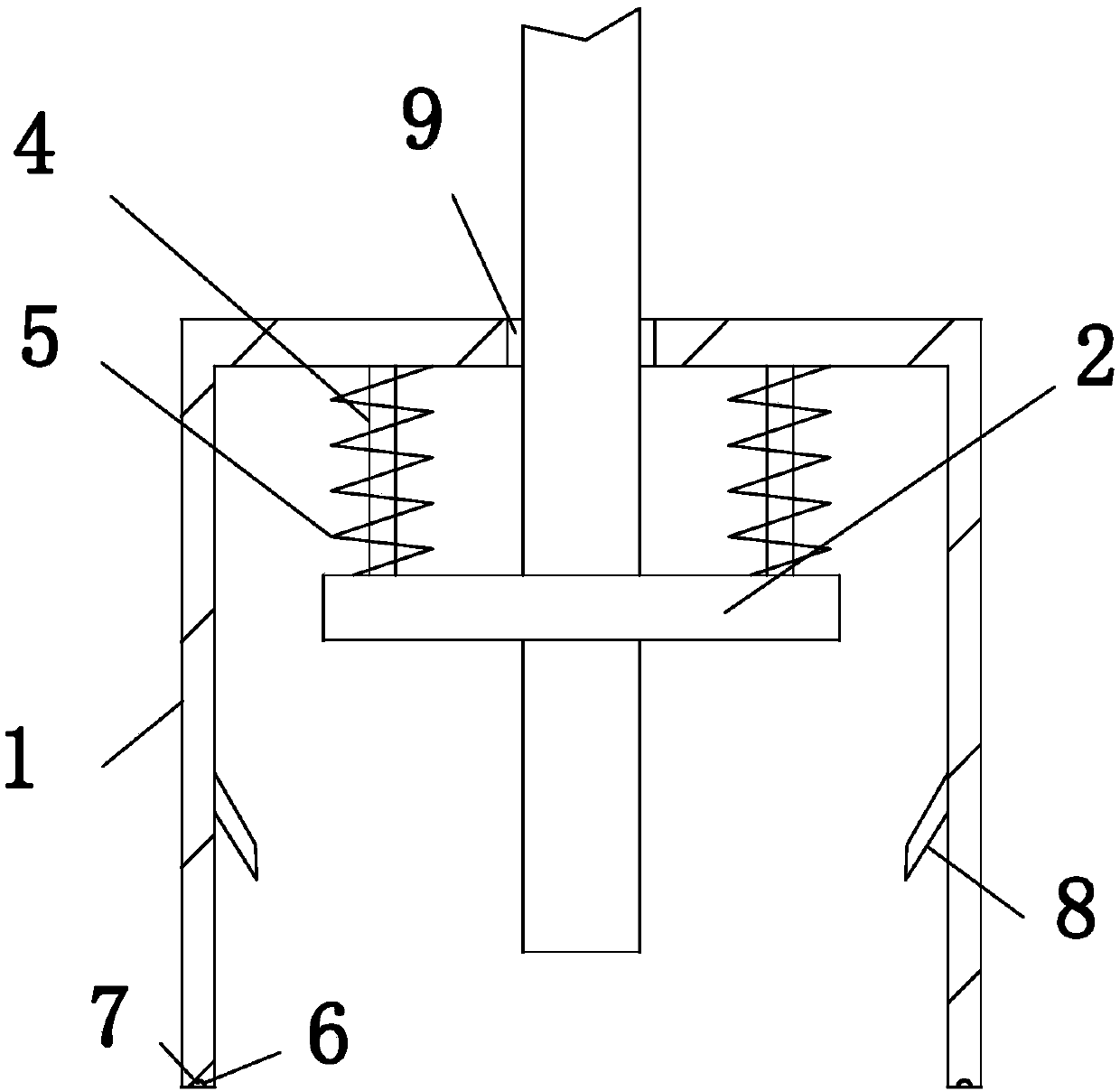

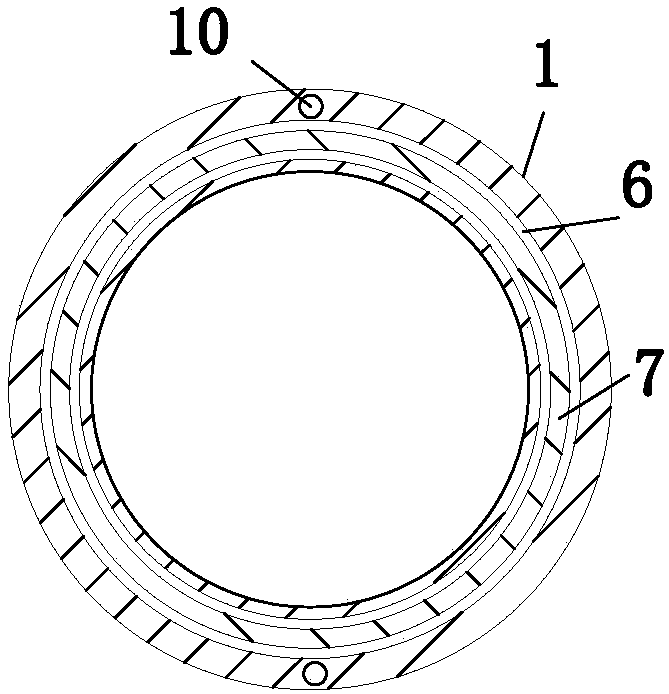

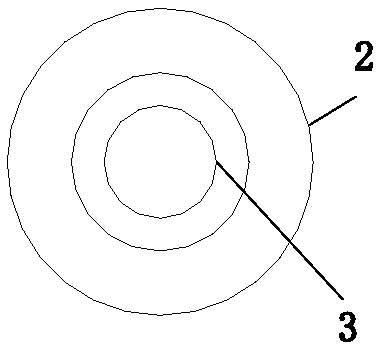

[0014] Example. A dust-proof device for sheet material punching equipment, which is constituted as Figure 1 to Figure 3 As shown, it includes a dustproof sleeve 1, the upper end of the dustproof sleeve 1 is provided with a through hole 9, the dustproof sleeve 1 is provided with an annular connecting piece 2, and the inner ring of the annular connecting piece 2 is provided with a bearing seat 3. A telescopic rod 4 is provided between the annular connecting piece 3 and the dustproof sleeve 1, and a return spring 5 is set on the telescopic rod 4, and the upper and lower ends of the returning spring 5 are respectively connected with the dustproof sleeve 1 and the annular connecting piece 2; The bottom of the dust-proof sleeve 1 is also provided with an annular slot 6, and a rubber strip 7 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com