Multi-slider matched molding structure of injection mold

A molding structure and injection mold technology, which is applied in the field of injection mold multi-slider matching molding structure, can solve problems such as affecting product assembly and handling, and cannot be adjusted automatically, achieving simple structure, reducing hard collisions, and reducing clamping line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

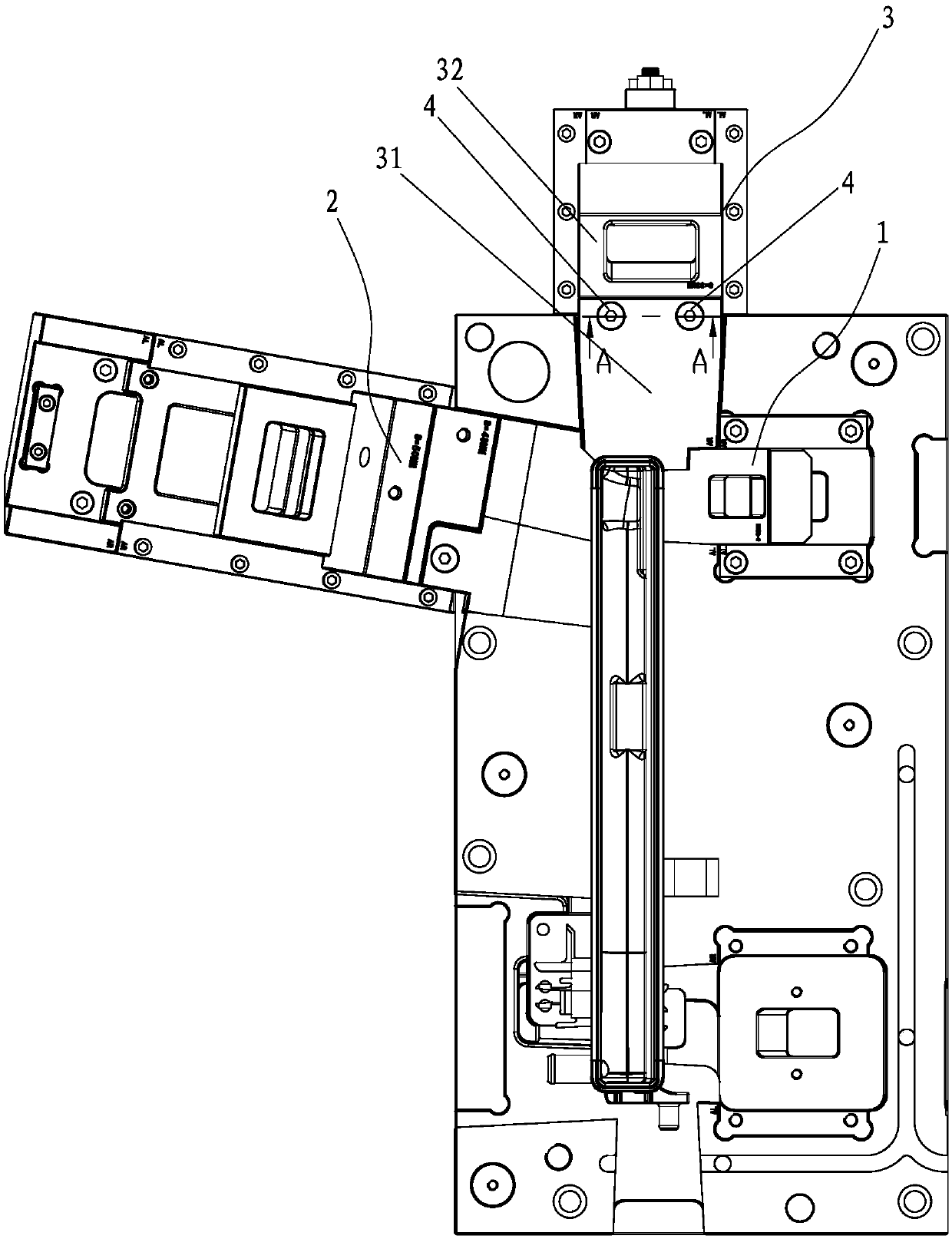

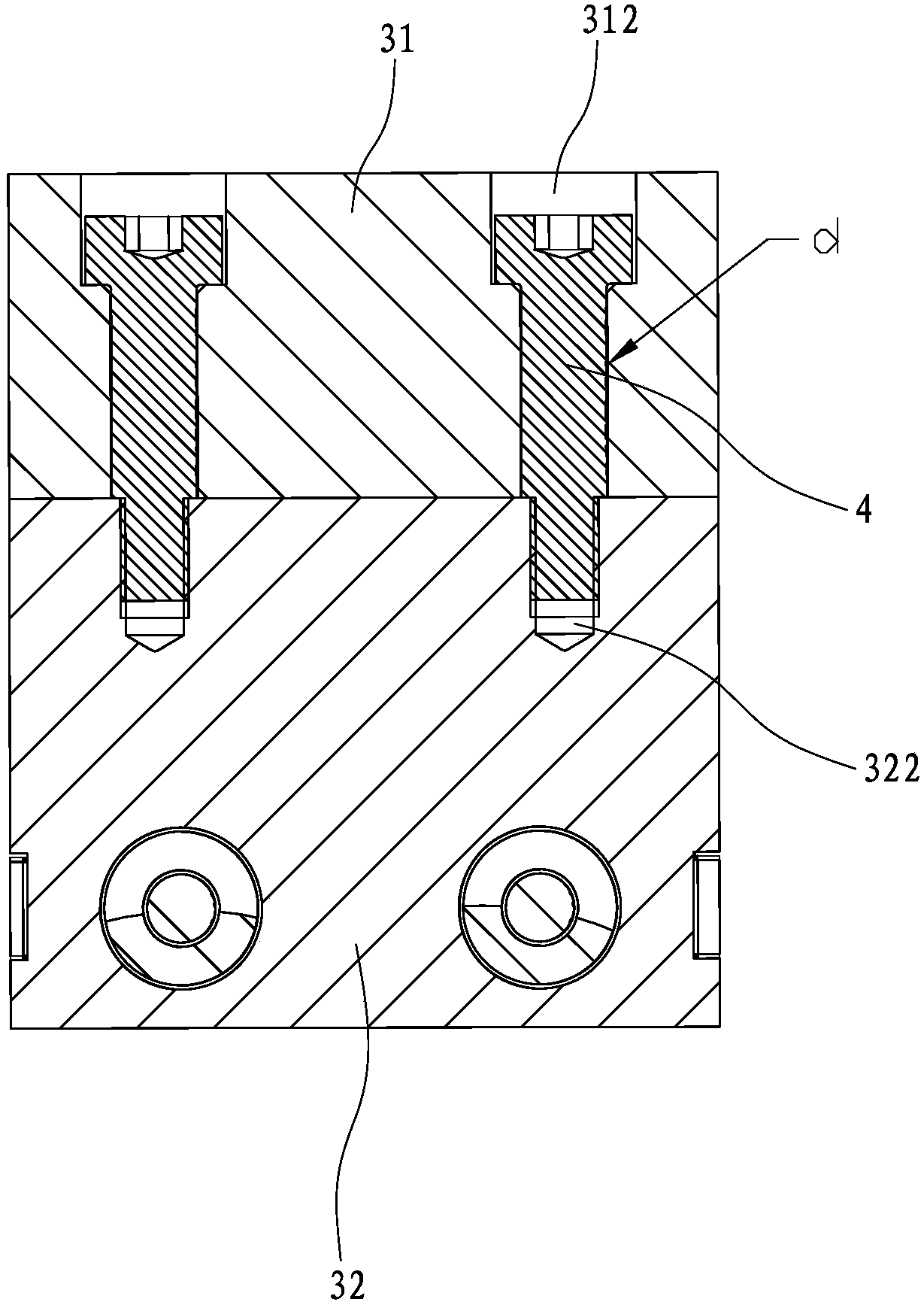

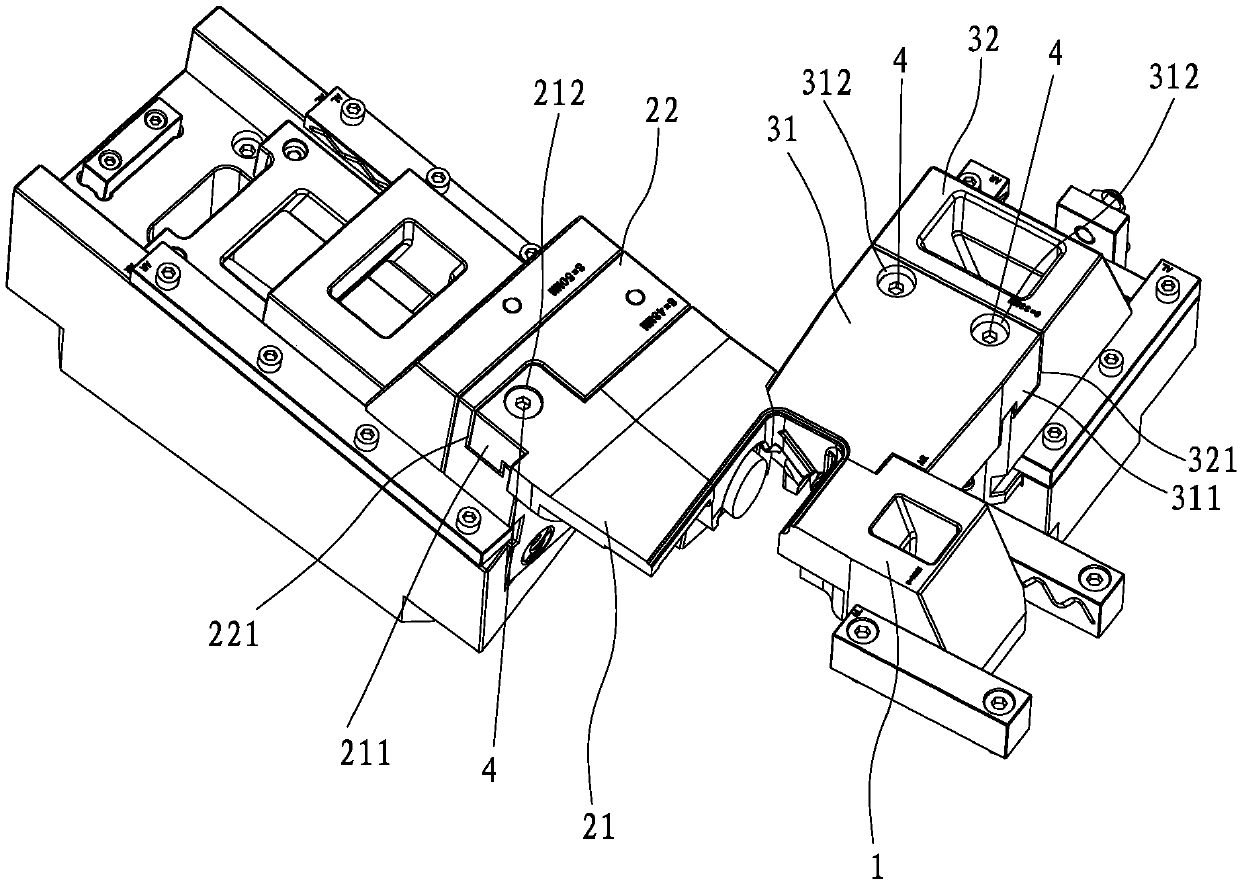

[0014] like Figure 1 to Figure 3 The shown multi-slider cooperative molding structure of an injection mold includes a first slider 1, a second slider 2 is provided on the opposite side of the first slider 1, and the first slider 1 and the second slider Between the two sliders 2, there is a third slider 3 that abuts against the two during molding, and the third slider 3 includes a third slider insert 31 and can be connected with the third slider insert 31. Disassemble the connected third slider body 32, the third slider body 32 is provided with a third connection groove 321 concave from top to bottom, the third connection groove 321 is provided with a third screw hole 322, The third slider insert 31 is provided with a third boss 311 which is inserted into the third connection groove 321 from top to bottom, and the third boss 311 is provided with a third boss corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com