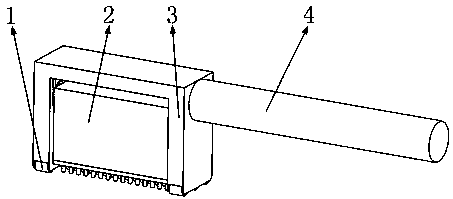

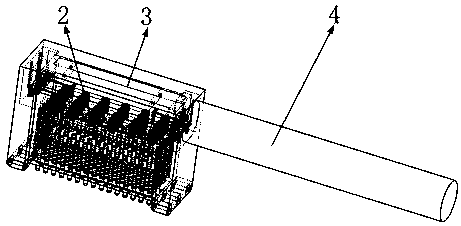

Swinging electrostatic garment care device

A nursing device and electrostatic technology, applied in the field of swing electrostatic clothing nursing devices, can solve the problems of torn clothes, unable to clean clothes, etc., and achieve the effect of preventing clothes from being damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

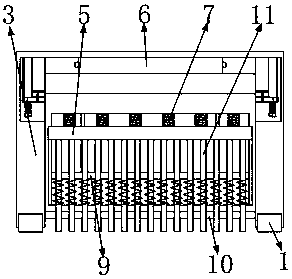

[0051]The specific embodiment: when people are using the bristle 11 device designed by the present invention; the bristle swing mechanism 2 and the U-shaped installation shell 3 on the bristle 11 device will be close to the surface of the clothes to be sorted, and then the bristle 11 device will be swung; simultaneously control the drive The motor 6 makes the drive motor 6 work; the drive motor 6 controls the rotation of the four drive shafts 26; the four drive shaft shafts drive the corresponding swing lever 24 to swing around the corresponding drive shaft axis; the swing lever 24 swings to drive the corresponding spring installation slider 22 swings around the axis of the corresponding drive shaft; the spring installation slider 22 swings to drive the corresponding spring installation shaft 21 to swing around the corresponding drive shaft axis; the spring installation shaft 21 swings through the corresponding drive spring 20 to drive the magnetic drive shaft 18 along the The ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap