Vibration shovel of railroad ballast tamping machine

A technology of tamping machine and vibrating shovel, which is applied in the field of vibrating shovel, can solve the problems of reduced work efficiency, easy wear, and influence on the effect of tamping slag, and achieves the effects of improving assembly accuracy, convenient use and installation, and improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

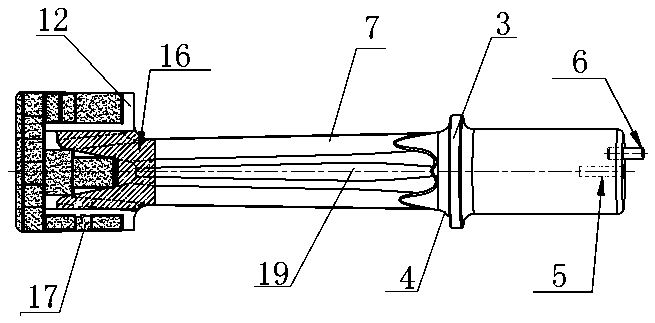

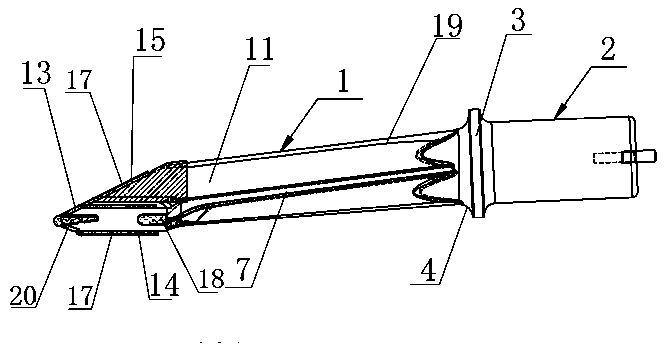

[0012] The invention will be described in detail below in conjunction with the drawings: Figure 1-3 As shown, the vibrating shovel of a railway ballast tamping machine according to the present invention is mainly made of a shovel body 1 in the front section and a cylindrical handle 2 in the rear section. The shovel body 1 includes a and The rear section of the conical handle 2 is a conjoined rod part 11. The front end of the rod part 11 has a plate-shaped shovel head 12 that extends forward and to both sides. The front end surface of the plate-shaped shovel head 12 forms There is a lateral right-angled triangular pointed corner 13, which is composed of a lower bottom plane 14 and an upper inclined plane 15. The upper inclined plane 15 and the rod 11 form the same inclined plane, and the inclined plane of the rod 11 is formed with For the wear resistant layer 16, the upper and lower planes of the plate-shaped shovel head 12 are also formed with a cemented carbide layer 17, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com