Multifunctional snow throwing device

A snow throwing device and multi-functional technology, which can be used in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of waste of manpower and material resources, high price, short snow throwing distance, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

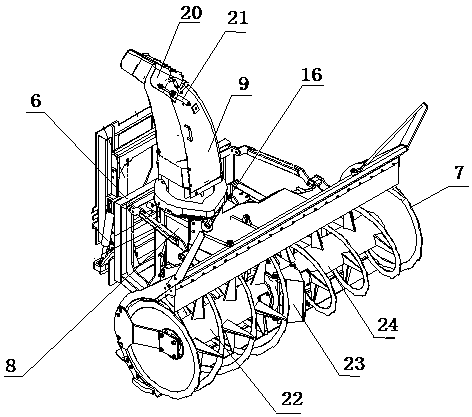

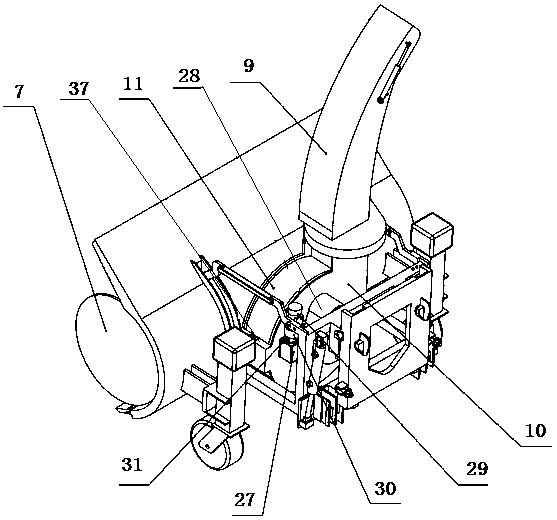

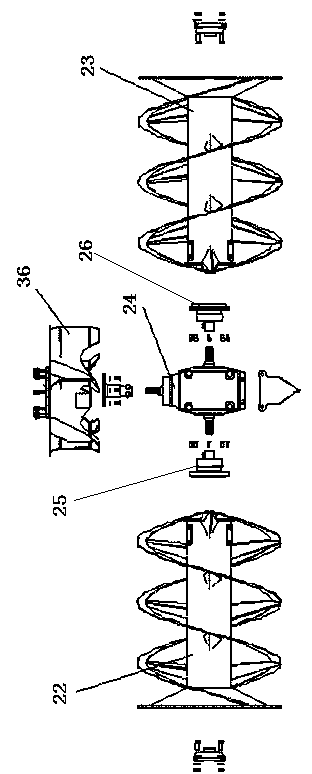

[0025]As shown in the accompanying drawings, a multifunctional snow throwing device includes a frame 6, a cage assembly 7, a thrower 8, and a snow guide cover 9, and the frame is provided with the cage assembly and the thrower. The upper end of the thrower is provided with a snow guide cover, and the thrower 8 is composed of an ejector 36, a high throw shell 10, a rotating housing 11, a connecting block 43, a front rotating housing turning device and a rear rotating housing turning device, Described high throw shell 10 is made up of front fixed plate 13, rear fixed plate 14 and connecting flange 15, and described front fixed plate 13 and rear fixed plate 14 are arranged in parallel, and described front fixed plate and rear fixed plate are respectively connected with machine The frame is fixedly connected, the upper ends of the front fixed plate 13 and the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com