High speed railway subgrade compaction index lossless calculating method

A technology for high-speed railways and subgrades, which is applied in the field of foundation soil survey, infrastructure engineering, construction, etc. It can solve the problems of consuming manpower, material resources and financial resources, destroying existing subgrade projects, increasing project investment, etc., to achieve fast operation, The effect of strong engineering adaptability and simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

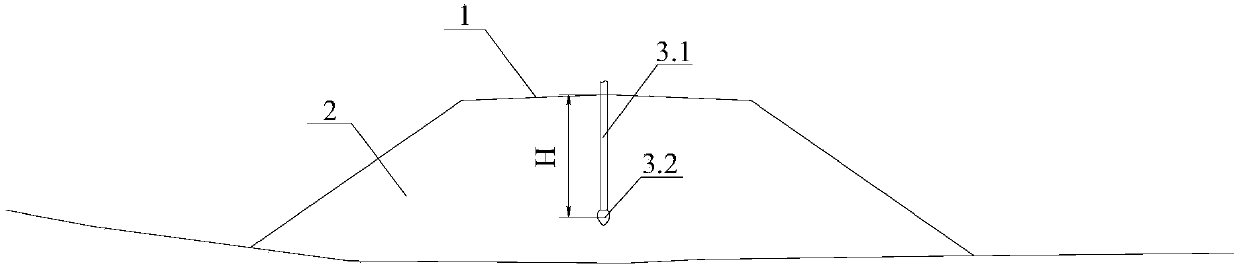

[0028] refer to figure 1 , a filling embankment of Iran's Deh-Iran (Tehran-Qom-Isfahan) high-speed railway was filled with a height of 4.2m.

[0029] In order to verify the feasibility of the method of the present invention, after measuring the number of hammer blows at different vertical depths H below the roadbed surface layer, the roadbed section is excavated layer by layer, and the in-situ test is carried out at the position corresponding to the dynamic penetrating hammering. Take compaction coefficient K and foundation coefficient K 30 and dynamic deformation modulus E vd . Adopt the inventive method below to measure and calculate this subgrade compaction index, concrete steps are as follows:

[0030] Step (1): along the figure 1 In the center of the subgrade surface layer, heavy-duty dynamic penetrating tests were carried out at vertical depths H of 0, 0.5, 1.2, 2.1, 3.1, and 4.0m, corresponding to the measured hammer number N 63.5 They are 24.8, 22.9, 34.0, 13.6, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com