Loader working device reset system

A working device and position limiting technology, which is applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve problems such as difficulty in adjusting the limit of working devices of loaders, and achieve simple structure, Improved work efficiency and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation will be described below in conjunction with the accompanying drawings.

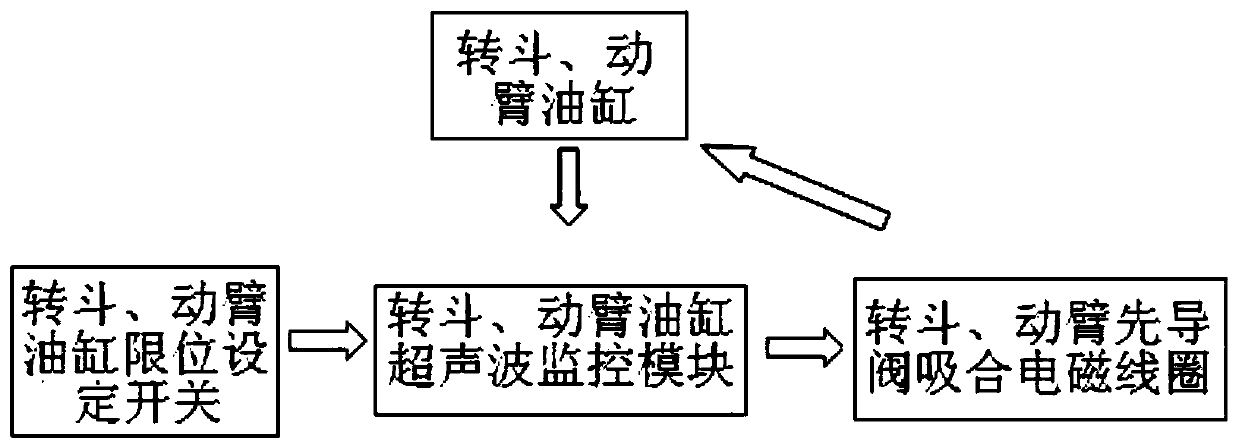

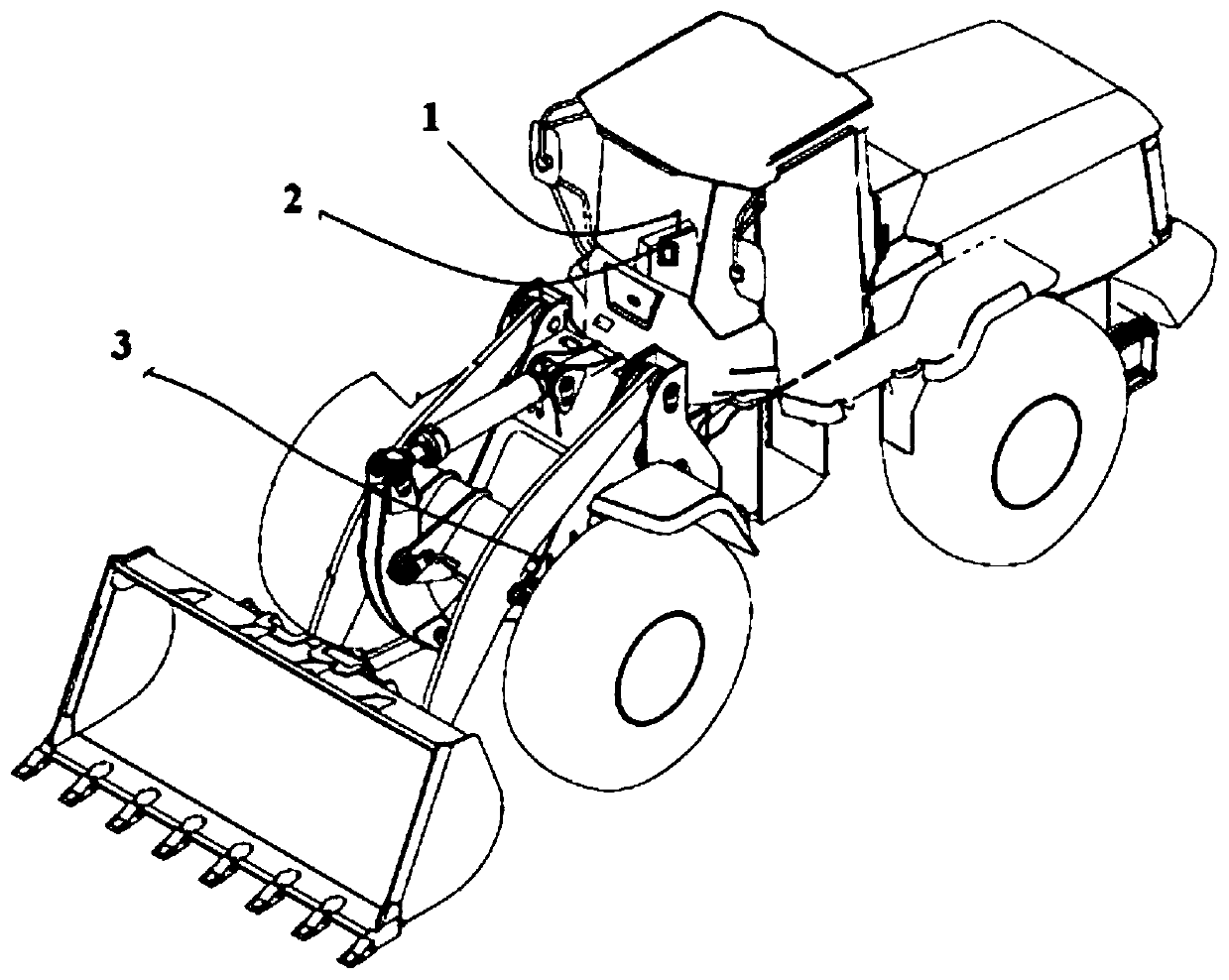

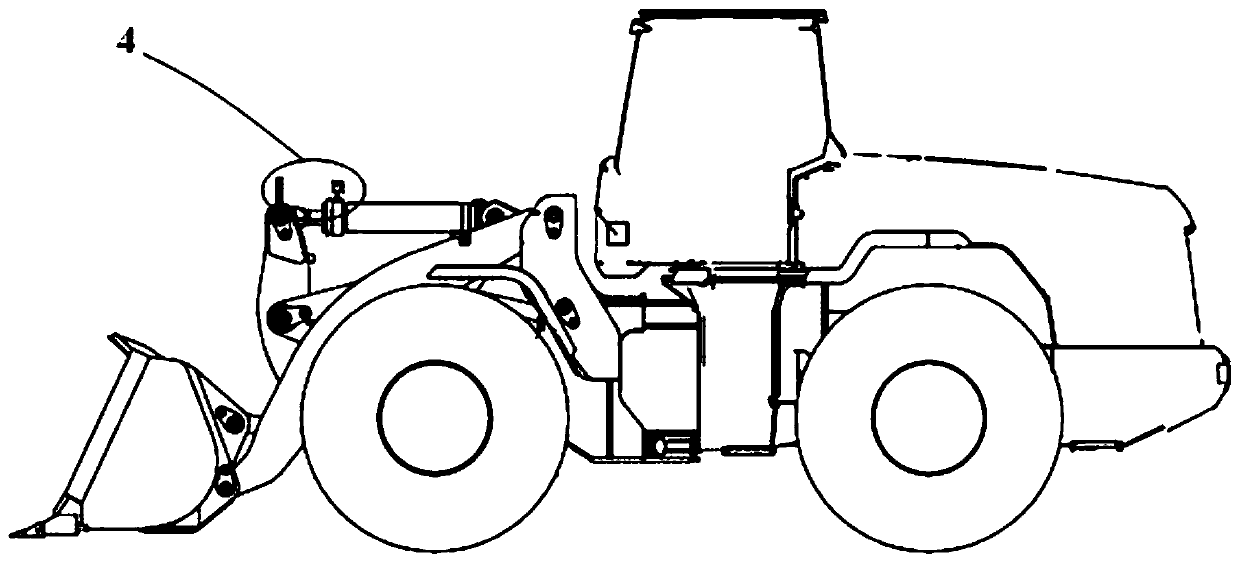

[0018] The reset system of the loader working device in the present invention is as follows: figure 1 , figure 2 image 3 and Figure 5 As shown, it includes a bucket limit relay 7 whose contact terminal is connected in series with the electromagnetic coil 8 of the rotary bucket pilot valve and a circuit in which the contact terminal is connected in series with the electromagnetic coil 6 of the boom pilot valve. Boom limit relay 5 on the top, bucket cylinder ultrasonic monitoring module 4 for detecting the extension of the piston rod of the bucket cylinder, and an ultrasonic monitoring module 3 for the boom cylinder used to detect the extension of the piston rod of the boom cylinder in the working device, The bucket oil cylinder limit setting switch 22 is connected with the ultrasonic monitoring module 4 of the bucket oil cylinder for setting the upper limit and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com