Synchronous control system and control method for multi-tire cable laying machine

A technology of synchronous control and cable laying machine, applied in the direction of mechanical equipment, optical fiber/cable installation, servo motor, etc., can solve the problems of inability to adapt to high-speed laying construction, etc., achieve strong adaptability to working conditions, reduce operation difficulty, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

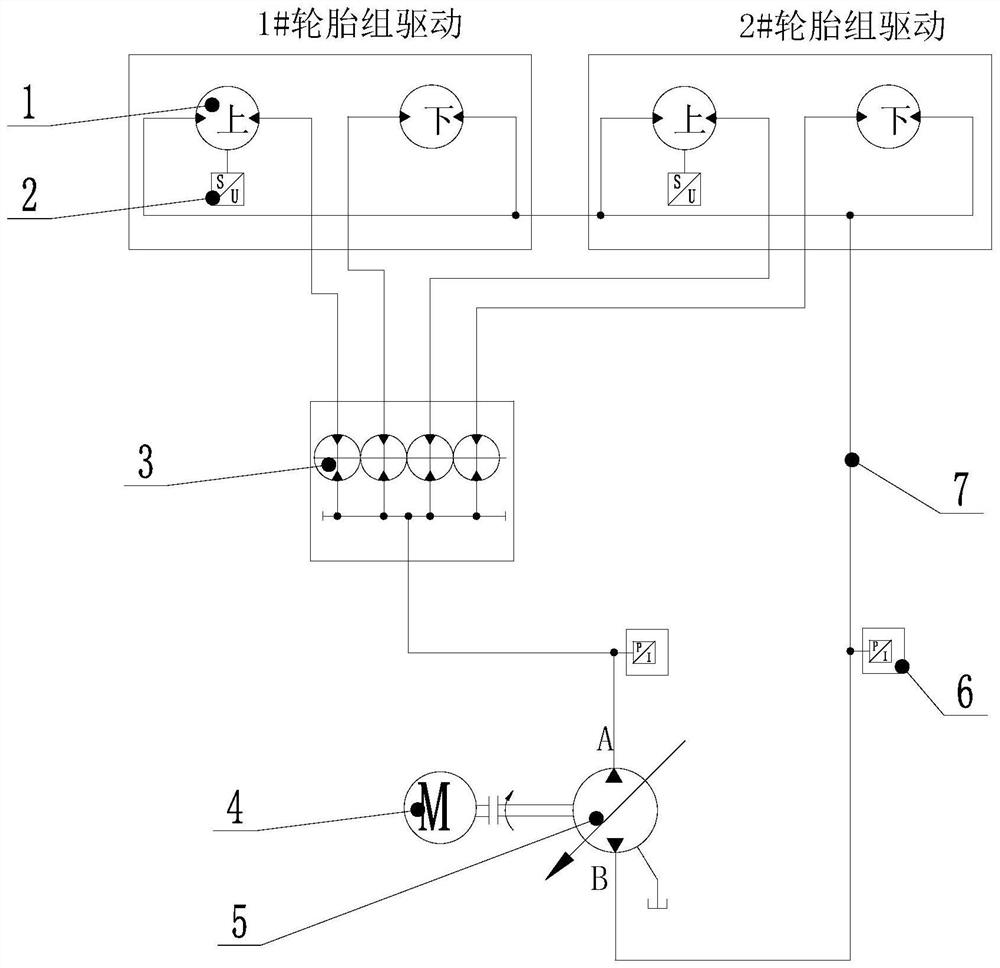

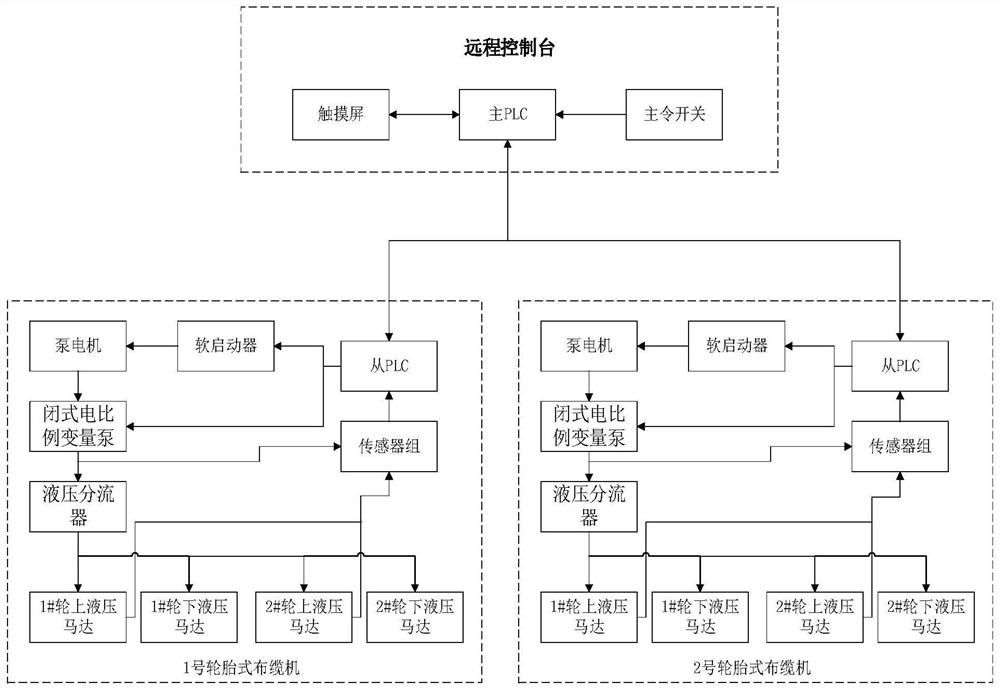

[0041] like figure 1 As shown, the technical scheme of the present invention is:

[0042] A synchronous control system for a multi-tire cable laying machine, comprising:

[0043] Multiple multi-tire cabling machines;

[0044] a data sensing module for obtaining the working parameters of the multi-tire cabling machine;

[0045] A control unit that receives the working data of the data sensing module, and further controls the working state of each multi-tire cabling machine according to the working data, so that the M multi-tire cabling machines realize synchronous action. in:

[0046] Each multi-tire cable routing machine includes:

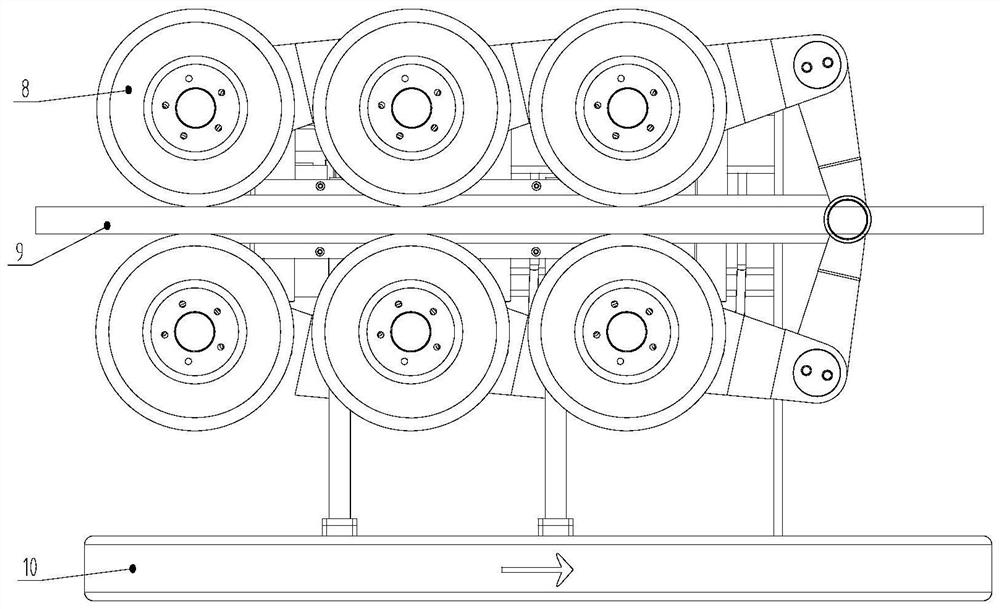

[0047] N groups of tires 8, each group of tires includes upper tires and lower tires; N is a natural number greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com