Gauge specialized for injection needle

A technology of injection needles and gauges, which is applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of large influence of subjective factors, poor data repeatability, low detection efficiency, etc., and achieve simplified detection operation steps, easy manufacturing and Simple effect of use and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

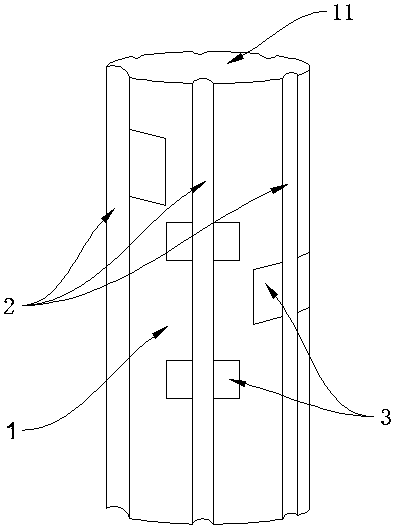

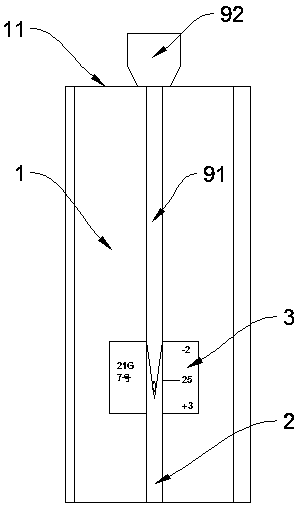

[0015] like figure 1 As shown, the special gauge for injection needles includes a cylinder 1, a number of card slots 2 and a scale slot 3. The clamping slot 2 is used to clamp injection needles of one or several specifications, and the scale slot 3 is used to detect whether the length of the injection needle of a specific specification meets the testing requirements.

[0016] The cylinder 1 is cylindrical, and the slots 2 are arranged parallel and vertically along the surface of the cylinder 1 . The outer wall of the cylinder 1 is integrated with a plurality of the card slots 2, which can be used for length detection of injection needles of various specifications. By rotating the cylinder 1, the corresponding engaging slot 2 can be selected for detecting injection needles of corresponding specifications.

[0017] The bottom surface 11 of the cylinder 1 is perpendicular to the outer surface of the cylinder 1, and each of the clamping grooves 2 is perpendicular to the end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com