Adaptive support apparatus and measuring system using the same

A support device and self-adaptive technology, applied in measuring devices, instruments, etc., can solve the problems of inability to eliminate the influence of gravity deformation, contour deformation, etc., and achieve the effect of reducing artificial contour deformation, eliminating influence, and accurate contour parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

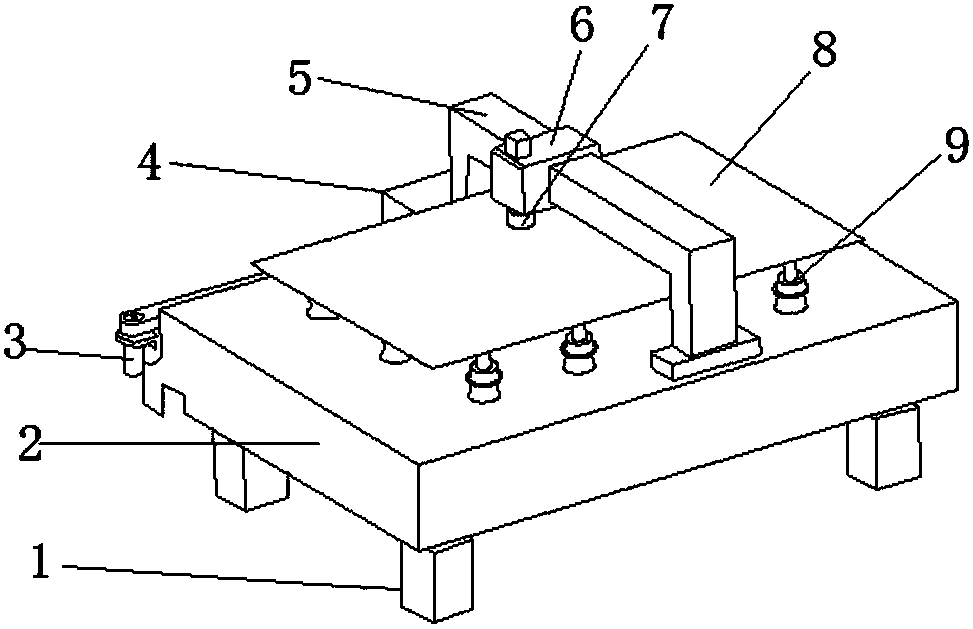

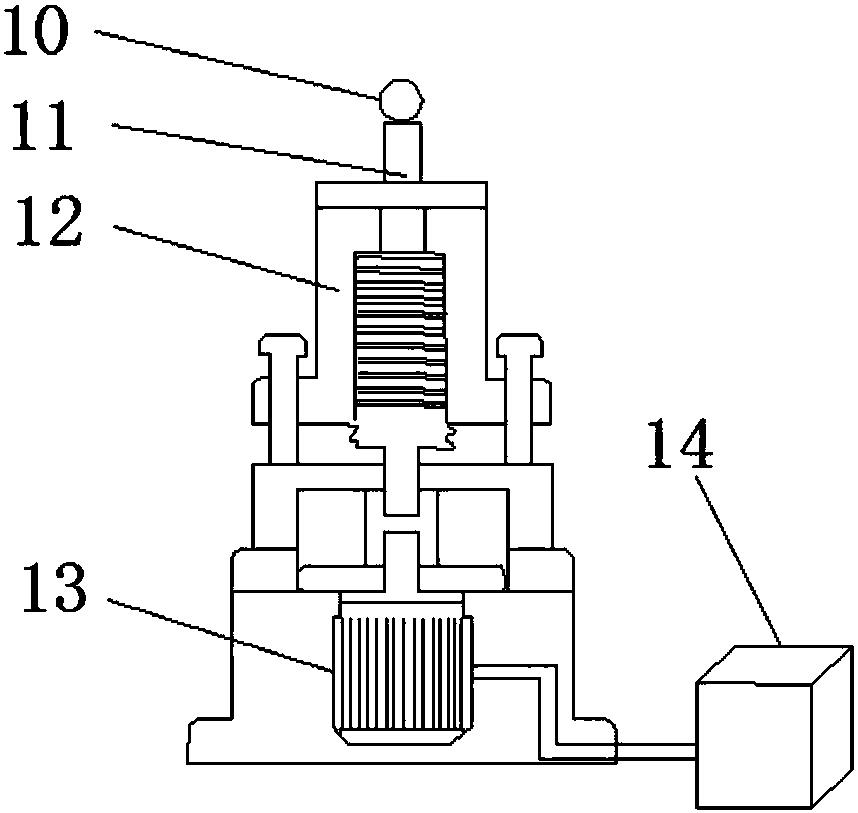

[0028] combine Figure 1 to Figure 3 As shown, the present embodiment provides an adaptive support device, which includes: a measuring mechanism and a supporting point mechanism; the measuring mechanism and the supporting point mechanism are used in cooperation with each other, please refer to the following description for details:

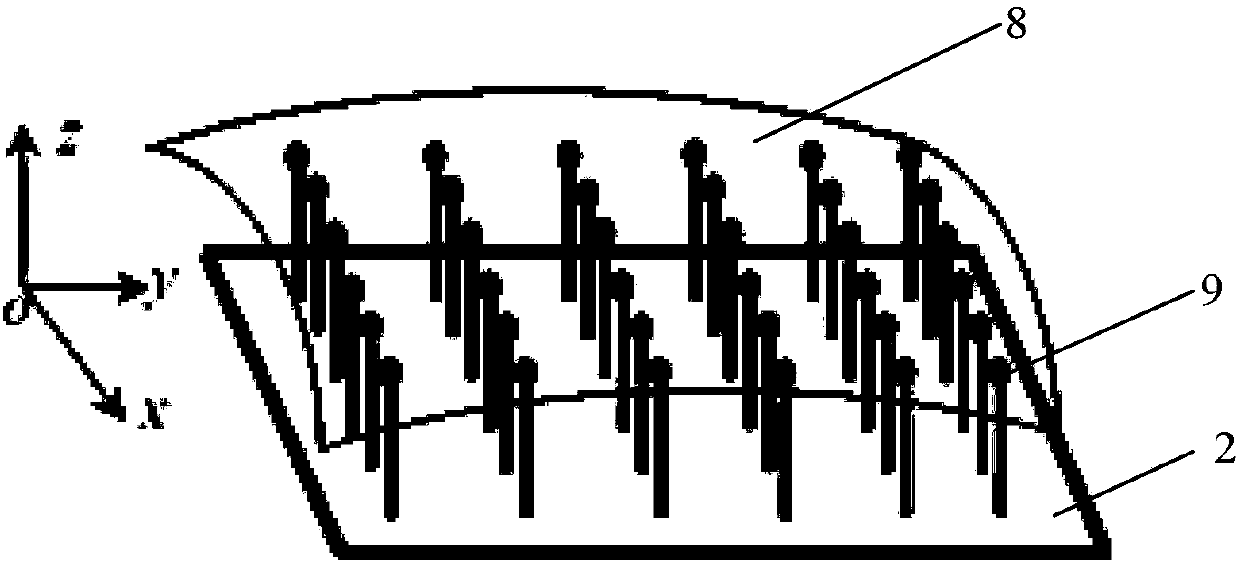

[0029] Wherein, the measuring mechanism includes: a platform 2, a three-dimensional motion mechanism and a probe unit 7, and the three-dimensional motion mechanism is used to drive the probe unit 7 to move above the platform 2, that is to say, the The probe unit 7 can move precisely in the X-axis direction, the Y-axis direction and the Z-axis direction above the platform 2 . As for the three-dimensional motion mechanism, its form can have various structures, as long as it can drive the measuring head unit 7 to perform three-dimensional motion.

[0030] Wherein, the support point mechanism includes several support point units 9 evenly distributed ...

Embodiment 2

[0050] combine Figure 1 to Figure 3 As shown, this embodiment also provides a measurement system, which includes the self-adaptive support device described in Embodiment 1. Of course, the measurement system may also include other auxiliary equipment besides the adaptive support device. For example: transportation equipment for loading large-size thin plate parts 8, or auxiliary equipment such as computers. The measurement system not only protects the adaptive support device, but also protects the application environment and application equipment of the adaptive support device.

[0051] Specifically, the self-adaptive support device includes: a measuring mechanism and a supporting point mechanism; the measuring mechanism and the supporting point mechanism are used in conjunction with each other, please refer to the following description for details:

[0052] Wherein, the measuring mechanism includes: a platform 2, a three-dimensional motion mechanism and a probe unit 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com