A water purifier power failure detection method

A technology of power failure detection and water purifier, applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve problems such as abnormal working status, inaccurate data, data loss, etc., and achieve the effect of avoiding data loss and abnormal machine operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

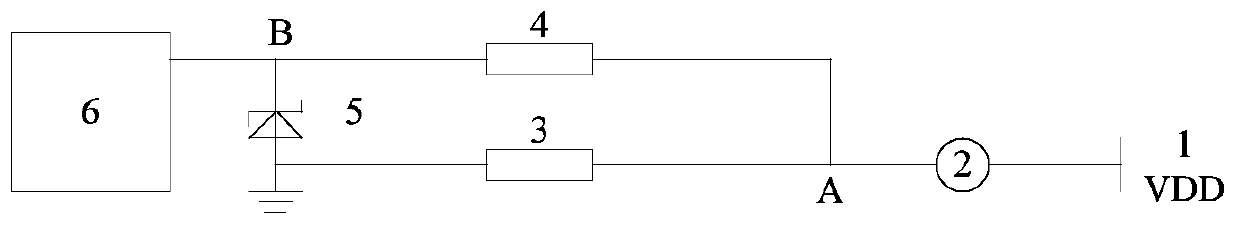

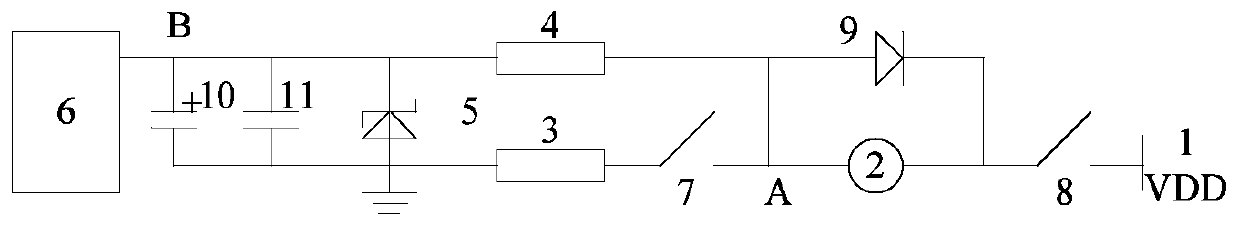

[0055] A water purifier power failure detection method, such as figure 1 As shown, the water purifier includes: a system power supply 1, a load 2, a first resistor 3, a second resistor 4, a Zener diode 5 and a main control chip 6; the main control chip 6 is used to sample the load current or load voltage ; Wherein, the system power supply 1, the load 2 and the first resistor 3 are connected in series successively and then grounded; the Zener diode 5 is connected in parallel between the sampling terminal of the main control chip 6 and the ground; end connected, and the other end is connected between the load 2 and the first resistor 3; as figure 2 As shown, the water purifier power-off detection method includes step S101:

[0056]S101. Determine whether the water purifier is powered off according to the magnitude of the sampling current or the magnitude of the sampling voltage of the main control chip.

[0057] In the embodiment of the present invention, the system power sup...

Embodiment 2

[0067] Based on the first embodiment, this embodiment provides a specific embodiment of judging whether the water purifier is powered off by the magnitude of the sampling current of the main control chip.

[0068] Optionally, as in Figure 4 As shown, judging whether the water purifier is powered off by the magnitude of the sampling current of the main control chip 6 may include S201-S203:

[0069] S201. When the water purifier is working, sample the load current, and compare the collected first sampled current with a pre-measured reference current;

[0070] S202. When the first sampling current is greater than or equal to the reference current, it is determined that the water purifier is not powered off;

[0071] S203. When the first sampling current is less than the reference current, re-sample the load current within the preset first time period, and compare the second sampling current obtained by sampling with the preset current threshold; when the second sampling current...

Embodiment 3

[0080] This embodiment further limits the current sampling method on the basis of the second embodiment.

[0081] Optionally, the reference current is obtained by averaging multiple samples of the load current, and the reference current is updated using a moving average filtering method.

[0082] In the embodiment of the present invention, the water purifier can continuously sample N times of current when it is working normally, and the current of N times of sampling is averaged as the reference current I D , due to the current I at the sampling terminal B point of the main control chip 6 B is the sampling current, then I D = I B =(I 1 +I 2 +…+I n ), among them, I 1 ~I n are the sampling currents of N times respectively. The scheme of this embodiment can verify the accuracy of the sampling current and avoid large errors caused by a single sampling.

[0083] In the embodiment of the present invention, the reference current may also be updated using a moving average fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com