Automatic vending machine capable of preventing goods from being damaged

A technology for vending machines and goods, which is applied in the direction of coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., which can solve the problem of easy breakage , unable to purchase large capacity or large packaging, damage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Further detailed explanation through specific implementation mode below:

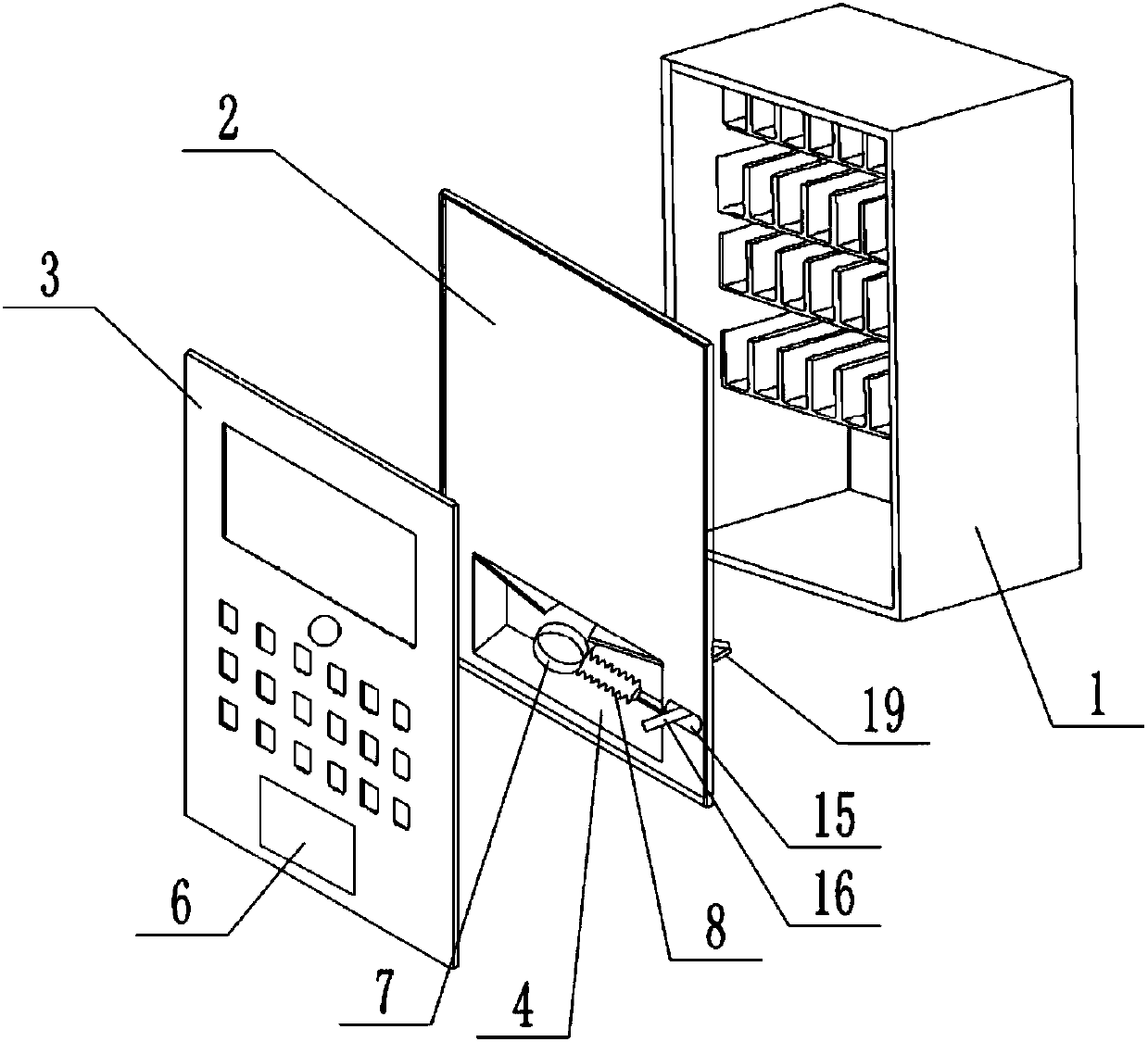

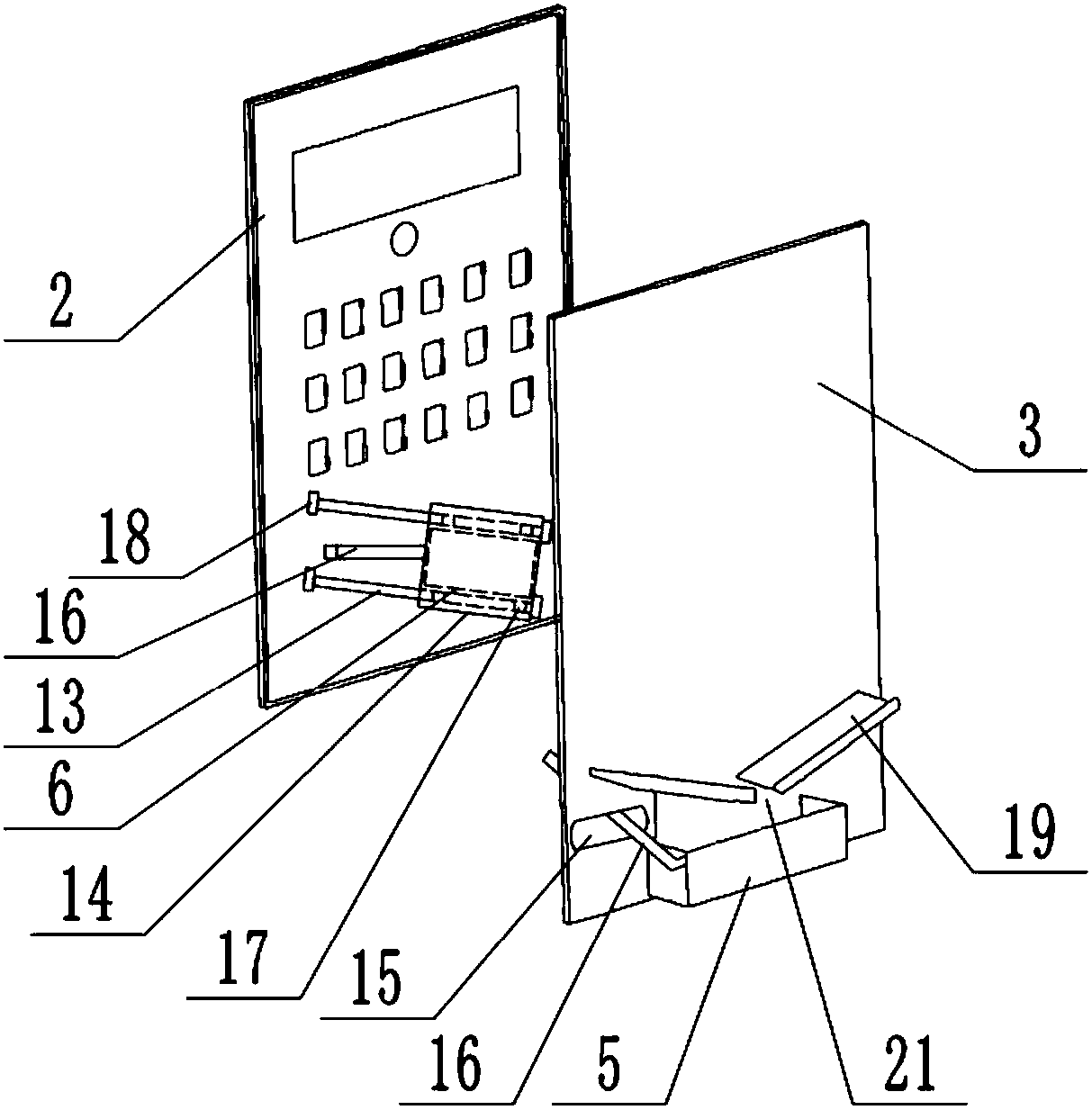

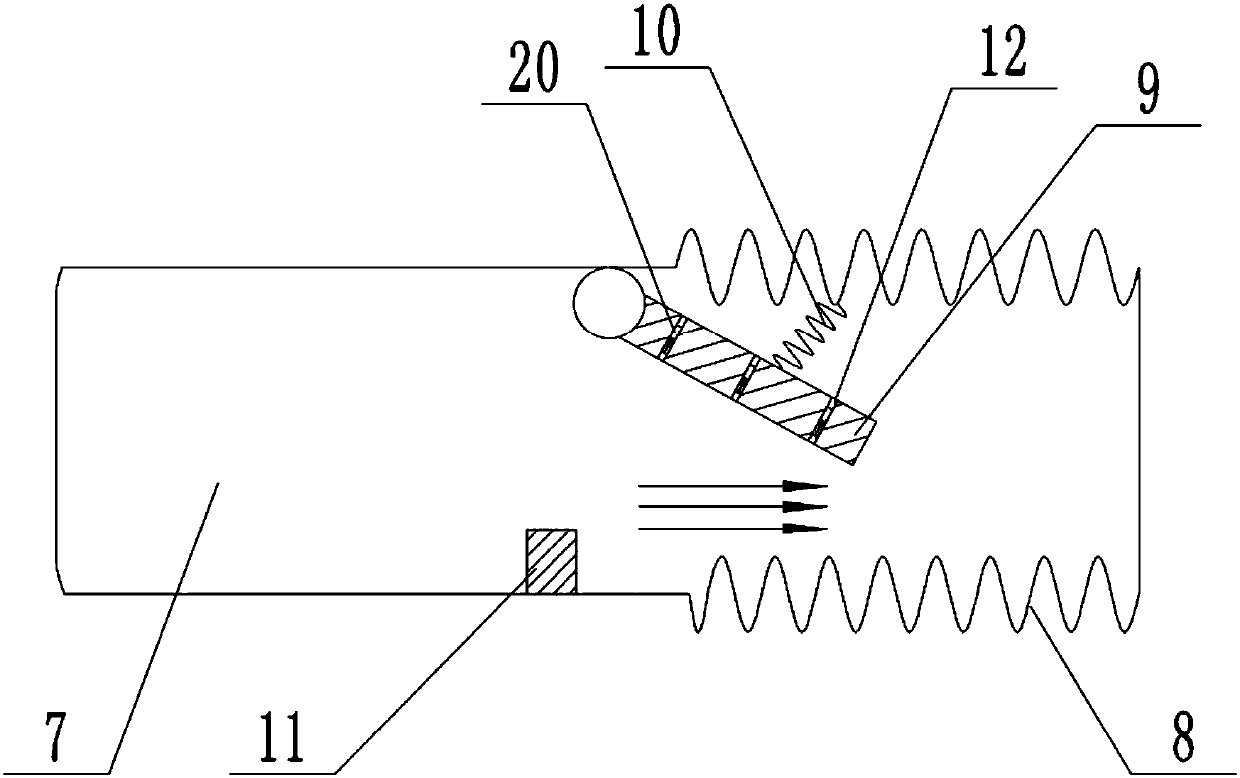

[0032] The reference signs in the accompanying drawings of the description include: cabinet body 1, panel 2, fixed plate 3, outlet 4, accommodation frame 5, cargo opening 6, first airbag 7, telescopic airbag 8, baffle 9, torsion spring 10 , Limiting block 11, fine hole 12, slide rail 13, baffle plate 14, strip hole 15, fixed rod 16, pulley 17, limiting mechanism 18, cargo guide plate 19, one-way valve 20, cargo inlet 21.

[0033] Explanation: The direction of the arrow in the figure indicates the flow direction of the gas.

[0034] Such as figure 1As shown, the automatic vending machine for preventing goods from being damaged in the present invention includes a rectangular cabinet body 1 with goods and a cabinet door arranged outside the cabinet body 1, and the cabinet door includes a panel 2 and a fixing bracket between the panel 2 and the cabinet body plate 3, the panel 2 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com