An overhead ground wire repair device

An overhead ground wire and repair pipe technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of reduced mechanical strength, hidden dangers, ground wire breakage, etc., to improve efficiency, ensure stability, and avoid disconnection accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

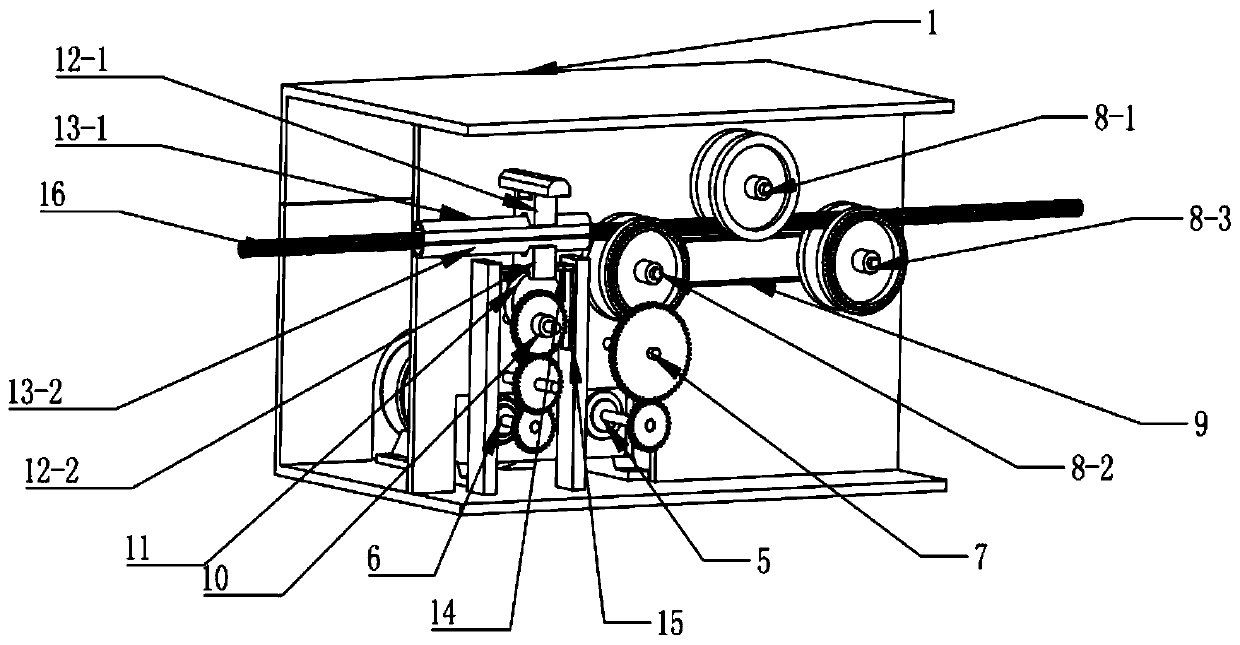

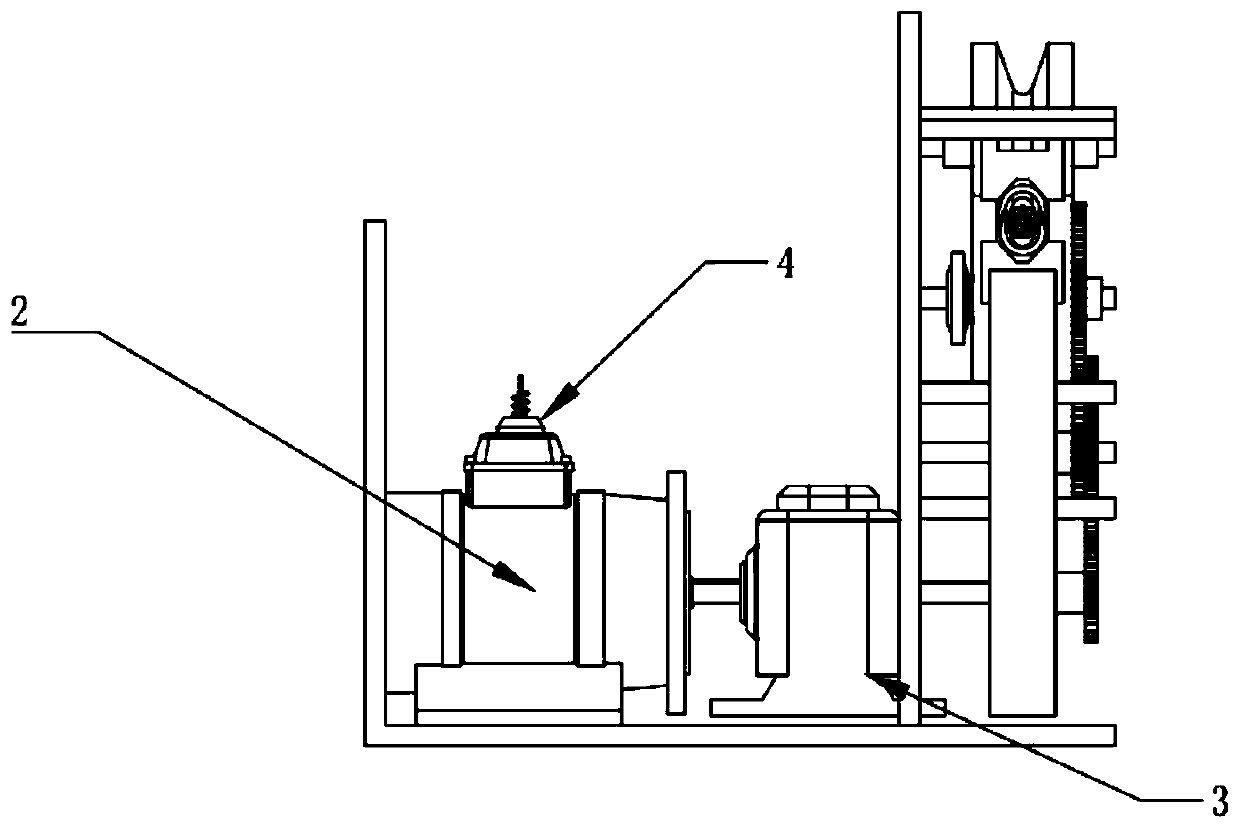

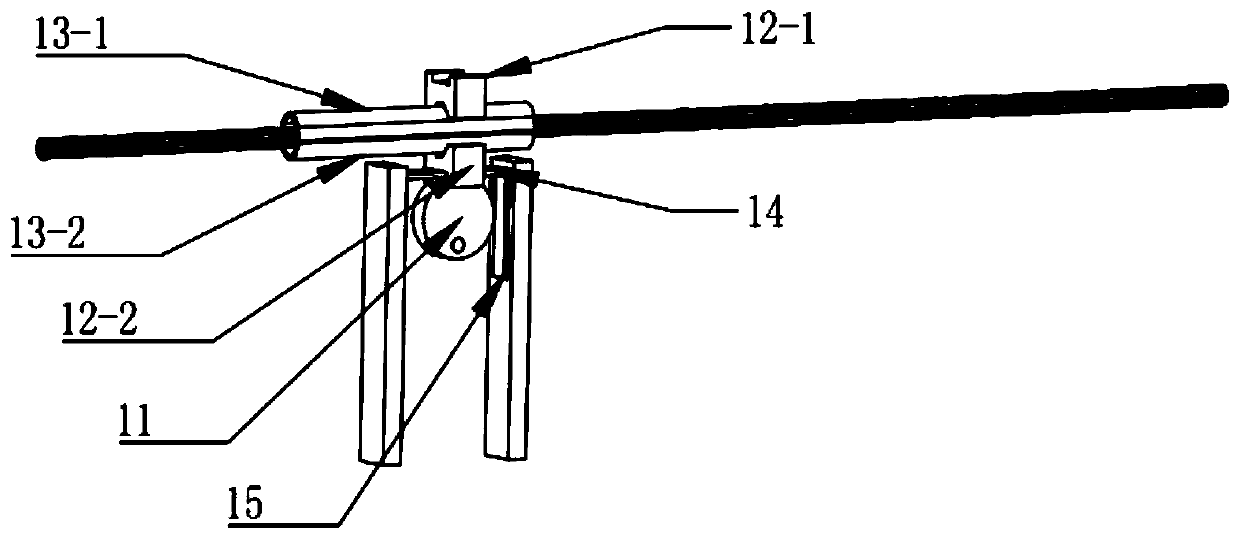

[0023] see Figure 1 to Figure 3 , the present invention provides an overhead ground wire repairing device, comprising a structural frame 1, a motor 2 and a clutch 3, the motor 2 is arranged inside the structural frame 1, the output end of the motor 2 is connected to the clutch 3, The top of the motor 2 is provided with a signal receiver 4 for receiving control commands, the clutch 3 is provided with a first port 5 and a second port 6, and a traveling device is provided above the first port 5, and the traveling device Connected to the first port 5, a pressing mechanism is arranged above the second port 6, a repair mechanism is arranged above the pressing mechanism, the repair mechanism is connected to the structural frame 1, and the pressing mechanism The tightening mechanism is used to compress the repairing mechanism. The repairing mechanism is used to repair the overhead ground wire 16. The signal receiver 4 above the motor 2 receives the operator's control instructions, an...

Embodiment 2

[0028] Compared with Embodiment 1, the difference in this embodiment is that the steel mold 12 is a regular hexagon, and both the upper steel mold 12-1 and the lower steel mold 12-2 are half of the regular hexagon and symmetrical to each other. The upper repair pipe 13-1 is a large semicircular hollow pipe that fits with the overhead ground wire 16, and the lower repair pipe 13-2 corresponds to a small semicircular hollow pipe, which can make the device more firm after crimping , can also ensure the electrical conductivity of the repaired overhead ground wire 16.

Embodiment 3

[0030]Compared with Embodiment 1 and Embodiment 2, the difference in this embodiment is that the distance between the road wheel 8-1, the driving wheel 8-2 and the driven wheel 8-3 is the same as the diameter of the overhead ground wire 16, It can ensure that the device is close to the overhead ground wire 16 and runs smoothly. The motor 2 is a horizontal motor with feet, which makes the installation of the motor 2 more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com