Power loss dysfunction characterization

A power loss and failure technology, applied in surveying, wellbore/well components, directional drilling, etc., can solve problems such as inaccurate timing of independent sensors, difficulty in detecting or predicting downhole drilling failures, affecting variable timing drift of sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Turning now to the specific description of the preferred arrangements of the invention, it should be understood that the features and concepts of the invention may be embodied in other arrangements and that the scope of the invention is not limited to the described or illustrated embodiments. It is intended that the scope of the present invention be limited only by the scope of the following claims.

[0021] The following examples of certain embodiments of the invention are given. Each example is provided by way of illustration of the invention, which is one of many embodiments of the invention, and the following examples should not be construed to limit or define the scope of the invention.

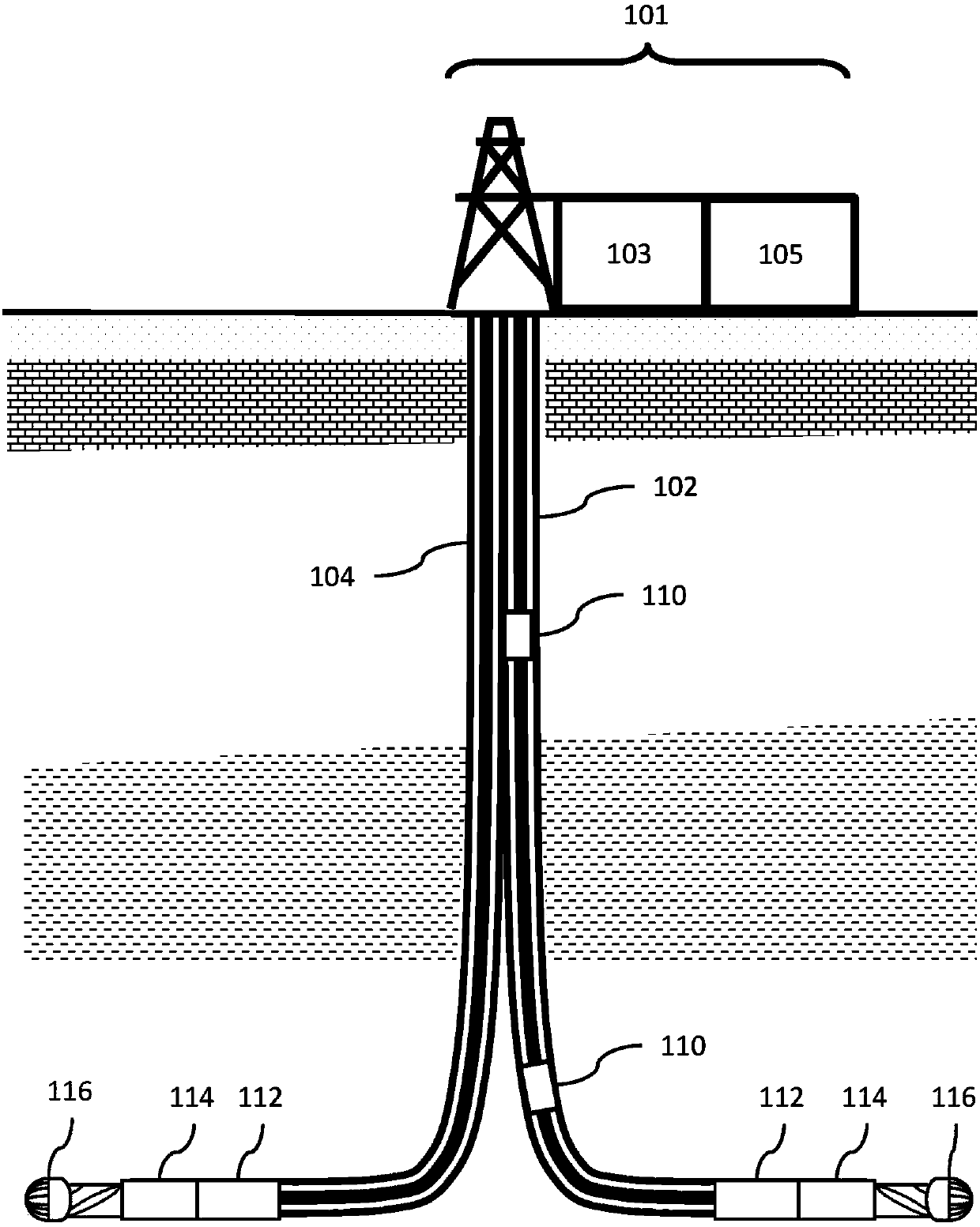

[0022] figure 1 An example of a formation having a first wellbore and a second wellbore according to various embodiments of the present disclosure is shown. The various embodiments disclosed herein are used in applications such as figure 1 The illustrated drilling environment i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap