Two-way chamfering tool

A chamfering tool and chamfering technology, applied in the direction of lathe tools, cutting blades, manufacturing tools, etc., can solve the problems of poor adaptability, non-adjustable elastic stiffness, increased tool change time, etc., and achieve operability Strong, adaptable, stable and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0031] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

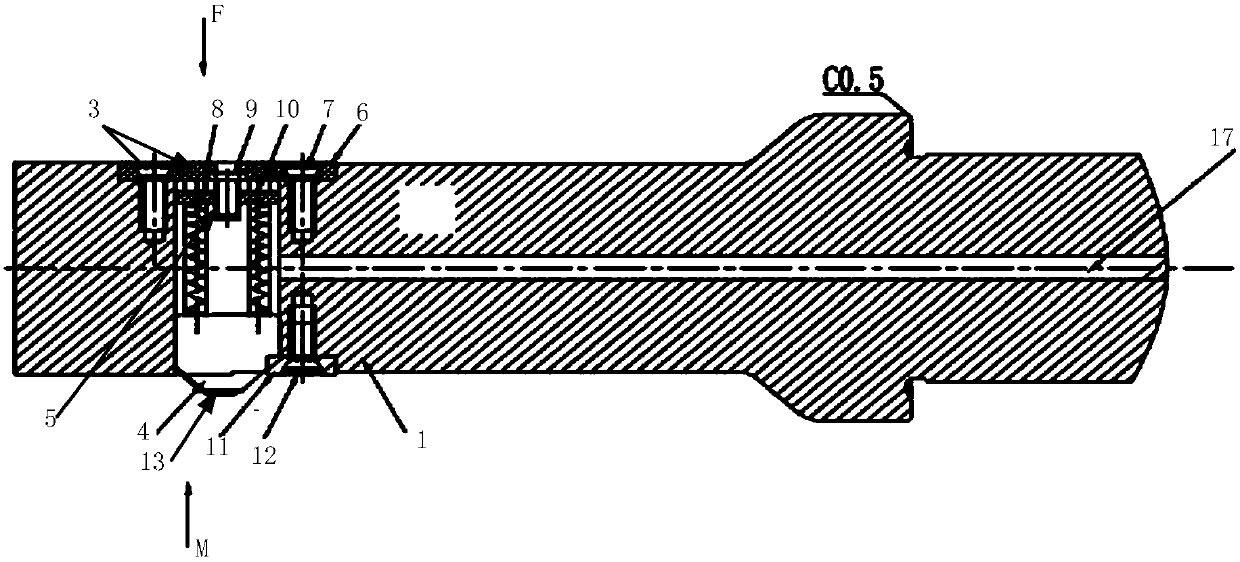

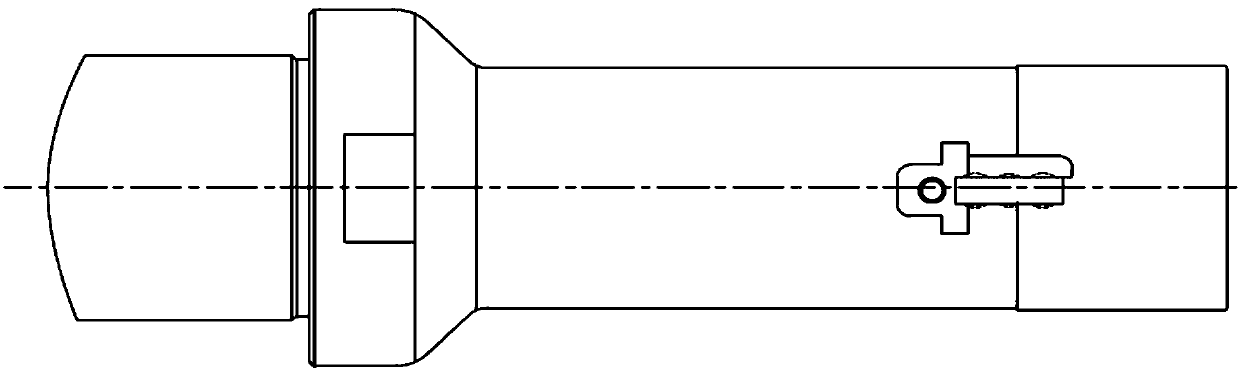

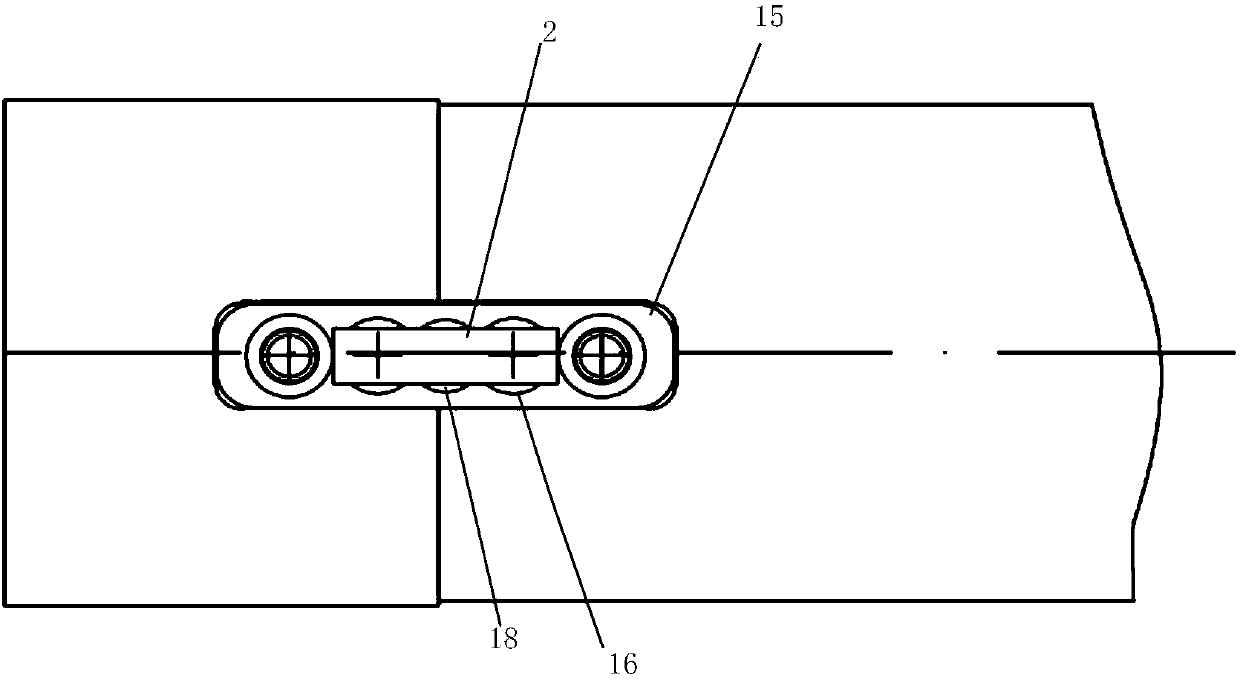

[0032] Figure 1-3 It shows an implementation form of a bidirectional chamfering tool according to the present invention, which includes:

[0033] The knife body 1 is provided with a square hole 2 perpendicular to the length direction of the knife body at the preset position of the front end, and one end of the square hole is detachably connected with a fixing part 3;

[0034] The two-way chamfering blade 4 is used to perform chamfering operations on the front and back sides simultaneously during hole processing; its connection end is connected to the fixing piece through an adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com