Multi-row lead frame structure

A lead frame and frame technology, applied in the direction of household components, household appliances, and other household appliances, can solve the problem that layering cannot realize one injection or multiple rows, and achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

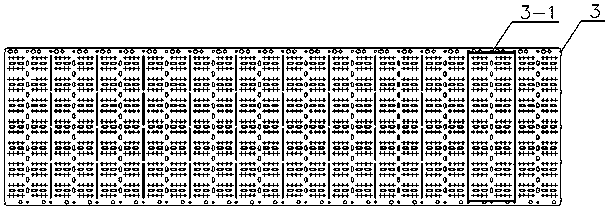

[0043] like Figure 3~Figure 5 As shown, a multi-row lead frame structure in this embodiment includes several frame units 3-1, each frame unit 3-1 is composed of two left and right column units 3-2, each column unit 3 -2 is composed of multiple rows of unit structures 3-3, each unit structure 3-3 is composed of several side-by-side products 3-4, and several main channels are arranged vertically between the left and right columns of units 3-2 Glue punching holes 3-5, at least one of the two adjacent sprue punching holes 3-5 are provided with several virtual runner punching holes 3-6 along the horizontal direction , the virtual runner hole 3-6 is located above or below the unit structure 3-3;

[0044] The number of unit structures 3-3 in each column unit 3-2 is 14 rows, 16 rows, 18 rows or 20 rows.

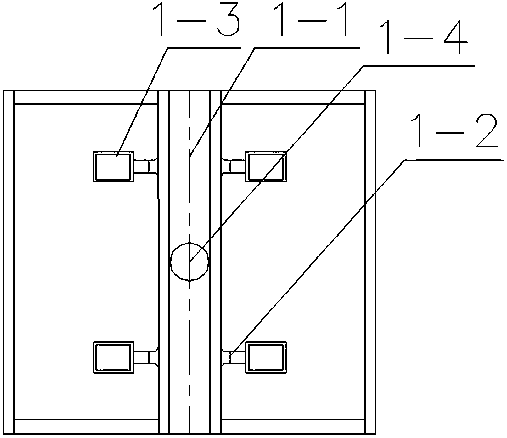

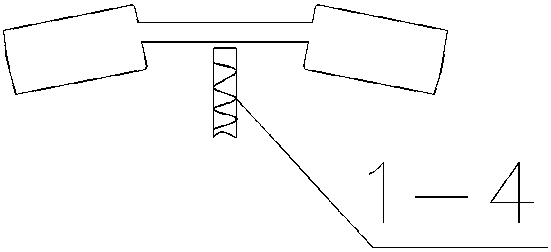

[0045] see Image 6 , a mold structure wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com