Dynamic spiral landscape device

A spiral and landscape technology, which is applied to stage installations, special decorative structures, installations used in theaters and circuses, etc., can solve the problems that cannot be separated for independent control, the driving force required for rotation is large, and the scene effect is monotonous. Achieve the effect of ensuring installation strength and operational reliability, good landscape effect, and unique and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

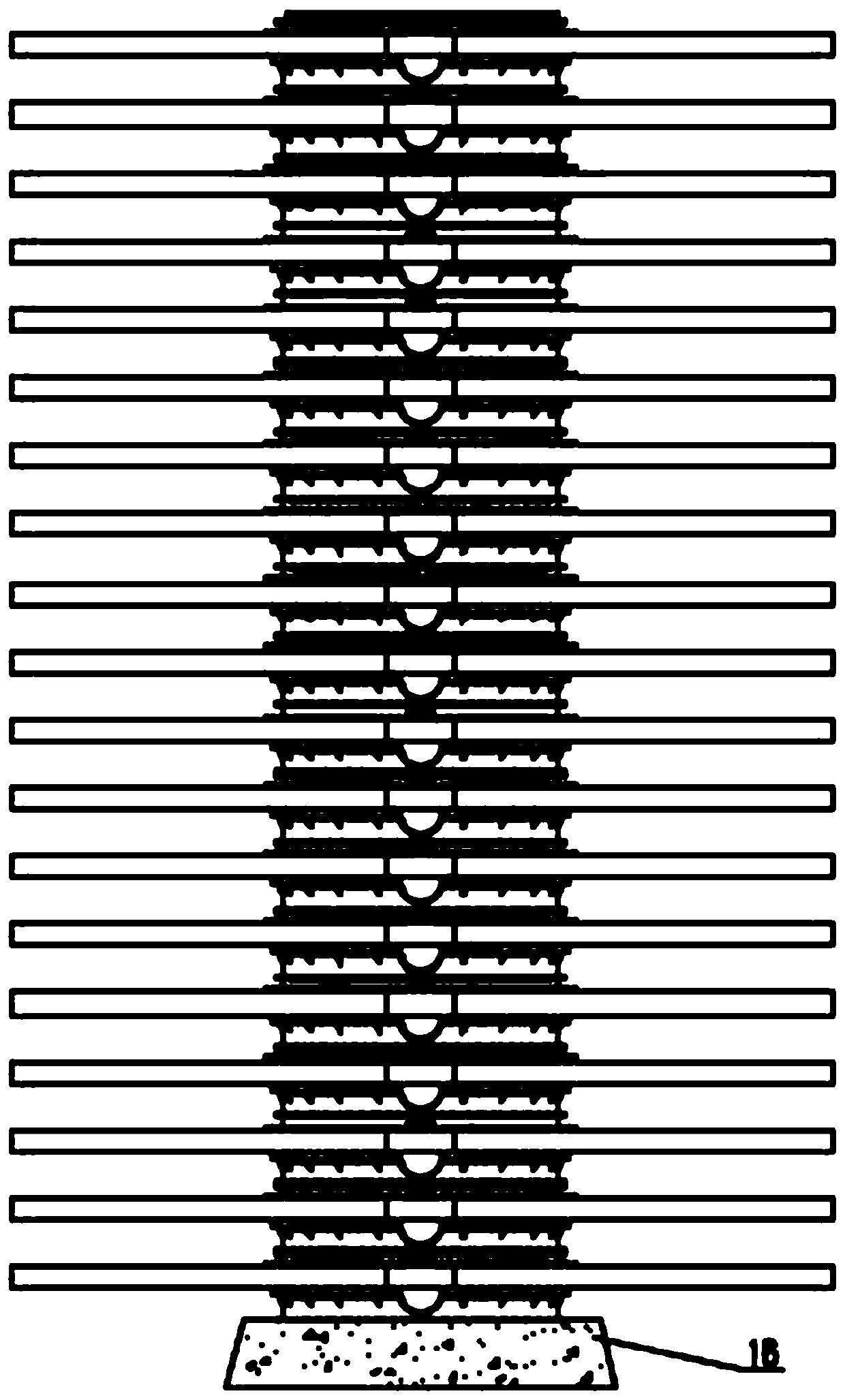

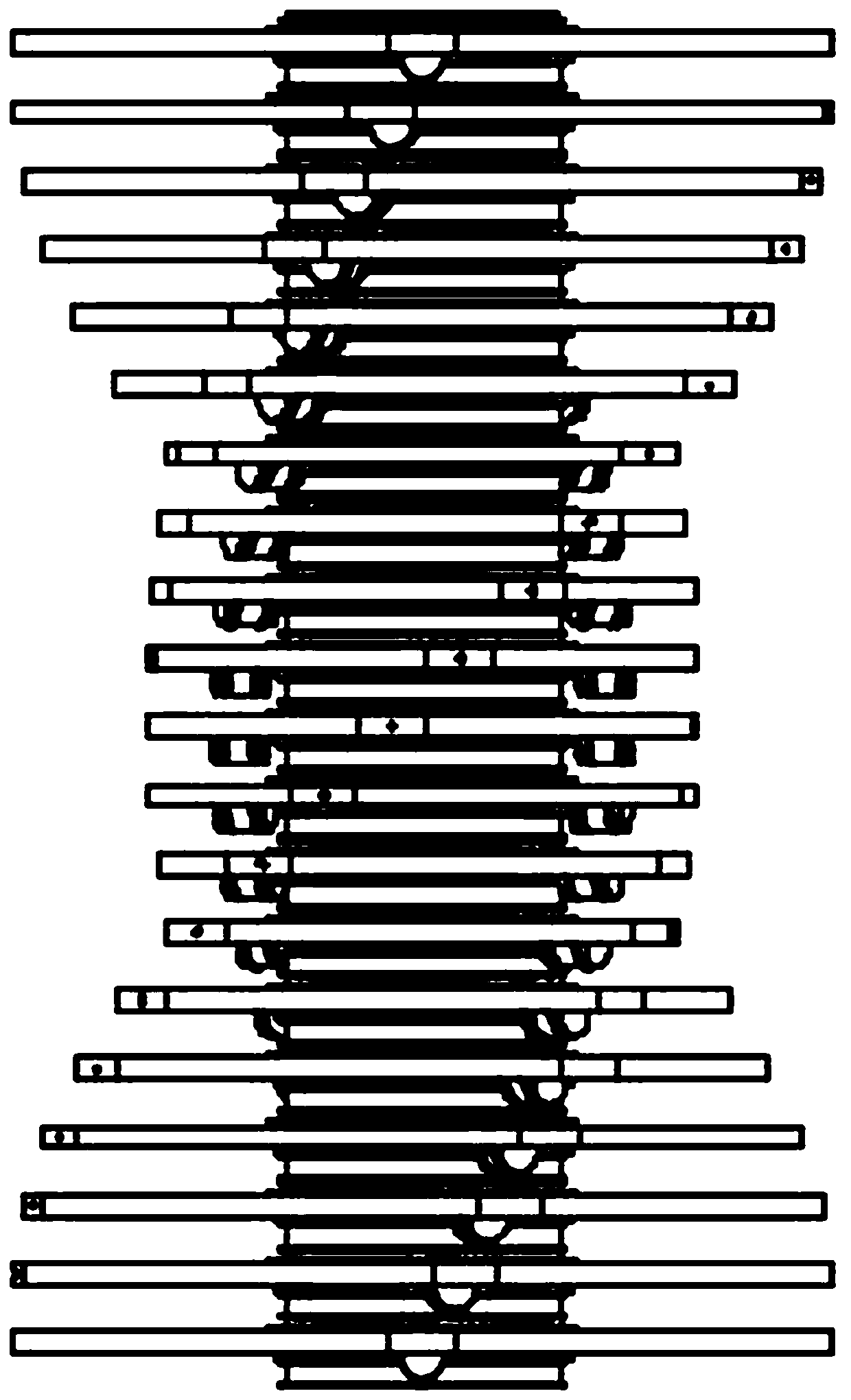

[0033] Such as Figure 1-3 As shown, the present invention can be assembled as figure 1 The cylindrical structure shown also includes a base 16 . Any one of the gear-driven rotary mechanisms is used as an independent rotary unit. The lower flange 10 of the fixed ring 1 of the gear-driven rotary mechanism at the bottom of the columnar structure is connected to the base 16 for fixed installation.

[0034] Each rotation unit includes an independent rotation drive mechanism, and the rotation angle of the rotation unit is precisely controlled by a servo motor. When the rotation angles of the rotation units are arranged in an arithmetic sequence, it can be as follows Figure 2-3 The spiral effect shown.

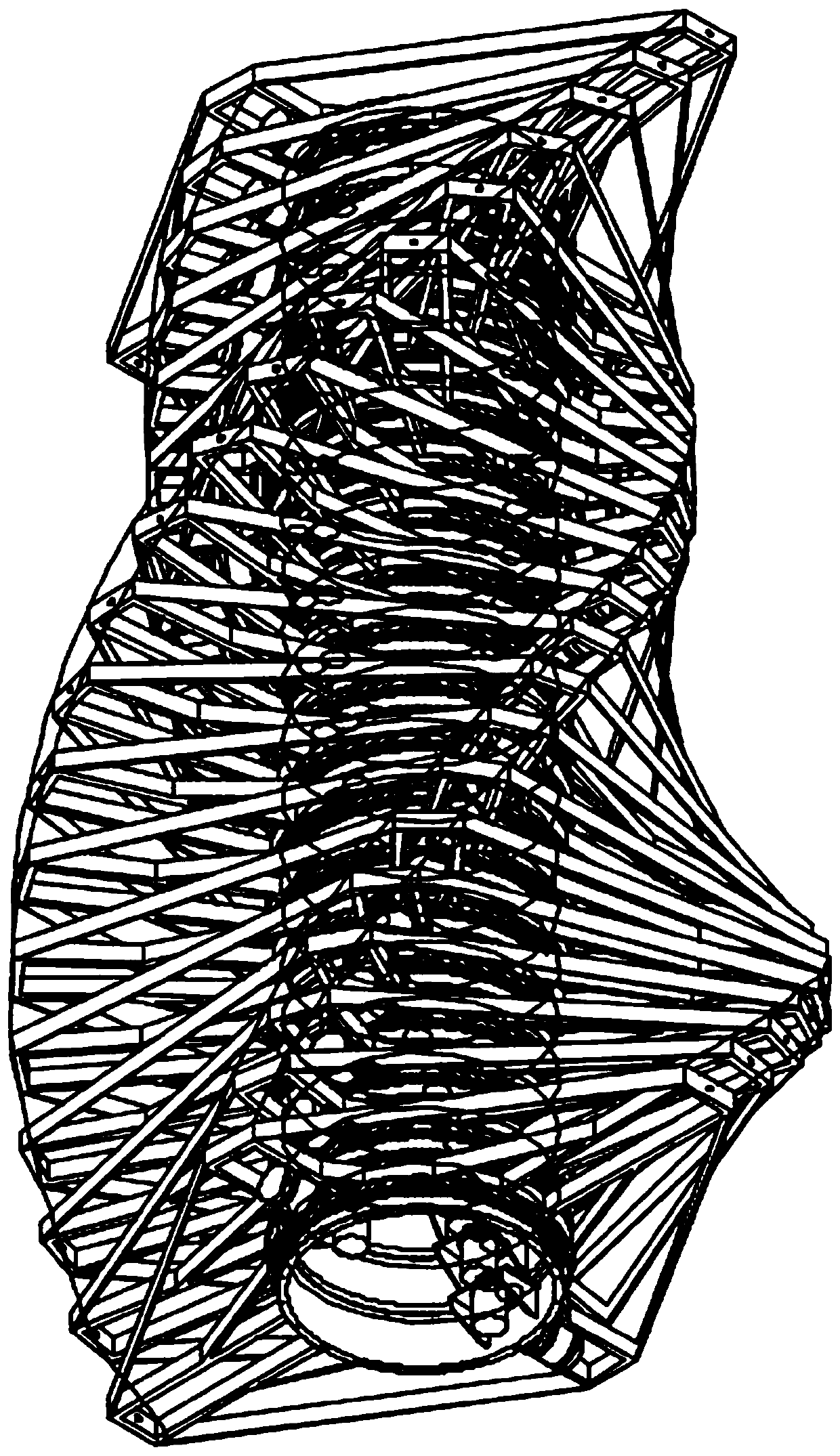

[0035] Such as Figure 4-6As shown, it is a structural schematic diagram of the rotating unit. The fixed ring 1 is a hollow cylindrical structure. The present invention installs two oppositely arranged along the center of the fixed ring 1 on the hollow inner wall of the fixed r...

Embodiment 2

[0036] Embodiment two, such as Figure 7 As shown, the said swivel frame 2 is a rhombic plate-shaped structure, and said rhombus-shaped plate-shaped structure is provided with a mounting groove, and a fuel tank 11 is installed on said mounting groove, and said diamond-shaped plate-shaped structure is also provided with Flame hole 12. As a method, the fuel tank 11 is arranged in the installation groove on the lower surface of the swivel frame 2, and is constrained by a restraint belt. The material of the restraint belt is not limited, and can be metal, leather and other materials. The fuel tank 11 and the flame injection hole 12 are connected with a control circuit, and the control circuit can control the flame injection time. The fire spray hole 12 is arranged at the end point away from the center of the fixed ring 1, so that after the present invention is assembled and installed, the fire spray will not affect other components, reducing component material damage and danger. ...

Embodiment 3

[0037] Embodiment three, such as Figure 8 As shown, the rotating frame 2 is covered with the casing, and preferably, the inner surface of the casing can just cover the outer surface of the rotating frame 2 . A through hole is provided in the center of the casing, and the diameter of the through hole is larger than the outer diameter of the upper flange 9 of the fixed ring 1 . In this embodiment, the upper flange 9 of the fixed ring 1 is higher than the rotating frame 2 , and the through hole of the casing is sleeved outside the upper flange 9 . The fire spray holes 12 corresponding to the fire spray holes 12 of the swivel frame 2 are provided on the casing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com