A kind of epoxy resin material and preparation method thereof

A technology of epoxy resin and epoxy hexane, applied in the field of epoxy resin materials and their preparation, can solve the problems of insufficient mechanical properties of room temperature curing epoxy, difficult to achieve anti-leaching properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

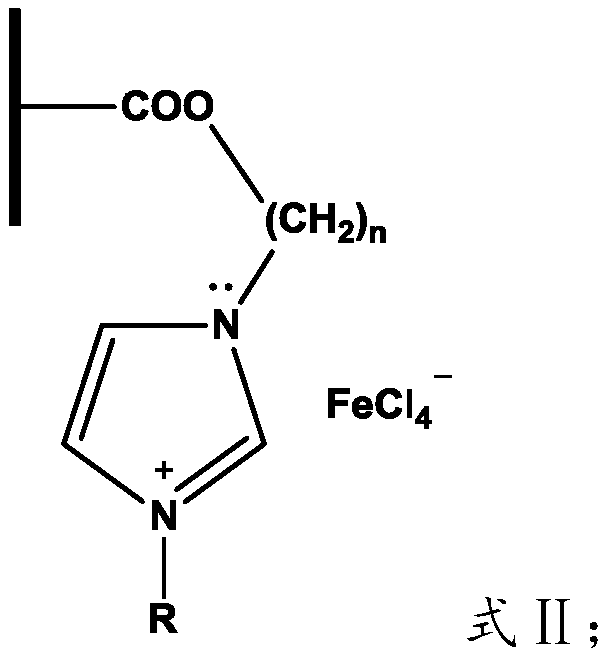

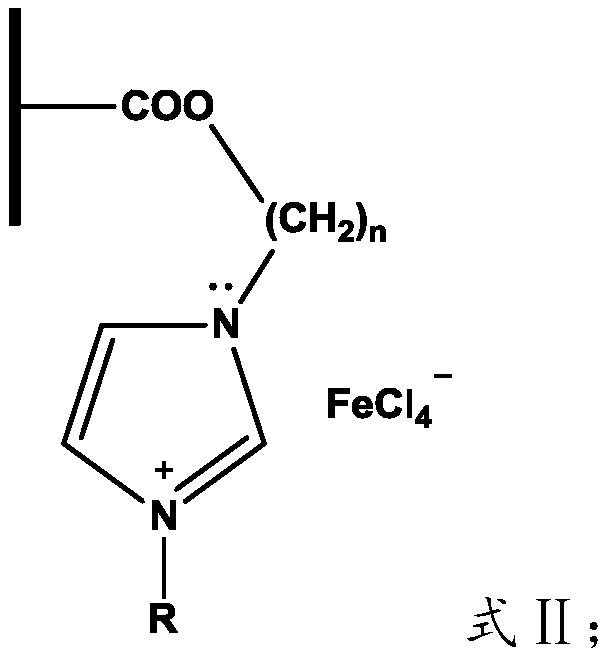

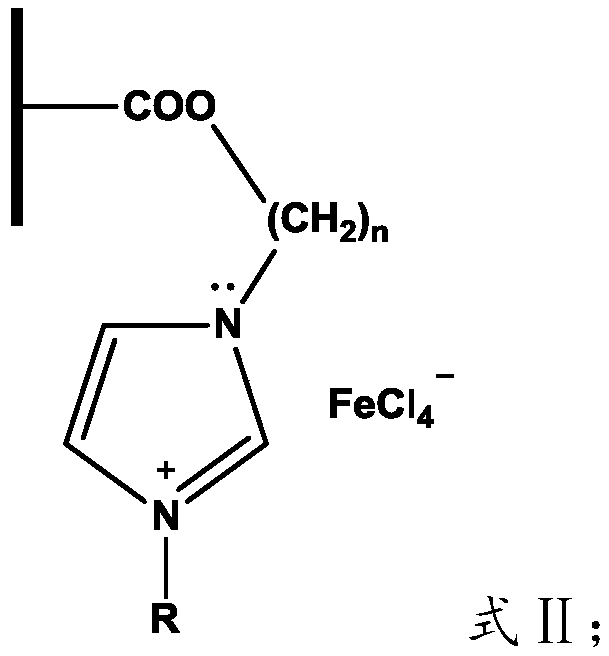

[0047] The raw materials for preparing the epoxy resin material provided by the invention include 10-20 parts of carbon nanotube-based iron-based imidazole ionic liquid. The carbon nanotube-based iron-based imidazole ionic liquid has the structure of formula II:

[0048]

[0049] The R is selected from -CH 3 ,-C 4 h 9 ,-C 6 h 13 or -C 11 h 23 .

[0050] In the present invention, the carbon nanotube-based iron-based imidazolium ionic liquid is preferably prepared by the following method:

[0051] a) reacting 1-alkylimidazole and methyl chloride to obtain 1-alkyl-3-methylimidazolium chloride salt ionic liquid; the alkyl group in the 1-alkylimidazole is selected from methyl, butyl, hexyl or deca An alkyl group; 1-alkyl-3-methylimidazolium chloride salt ionic liquid is reacted with ferric chloride to obtain an iron-based imidazolium ionic liquid;

[0052] b) In the presence of dimethylformamide, dicyclohexylcarbodiimide (DCC) and 4-dimethylaminopyridine (DMAP), react c...

Embodiment 1

[0069] Add a certain amount of dichloroethane, boron trifluoride·ether solution and ethylene glycol into the reaction kettle, stir evenly, start to add epichlorohydrin dropwise, and control the whole reaction temperature at 18-23°C. After the epichlorohydrin was added dropwise, the temperature of the reaction solution was raised to 40° C., and the reaction was carried out for one hour. After the reaction solution is cooled to room temperature, it is washed repeatedly with saturated sodium bicarbonate solution and deionized water until it becomes neutral, and dichloroethane is distilled off to obtain hydroxyl-terminated polyepichlorohydrin (PECH). Dissolve the self-made PECH in an appropriate amount of toluene, heat up to 90°C and add a certain amount of analytically pure NaOH. After reacting for four hours, add HCl aqueous solution to neutralize the remaining NaOH, and wash repeatedly with deionized water until the solution is neutral. properties, after distilling the toluene,...

Embodiment 2

[0079] Add a certain amount of dichloroethane, boron trifluoride·ether solution and ethylene glycol into the reaction kettle, stir evenly, start to add epichlorohydrin dropwise, and control the whole reaction temperature at 18-23°C. After the epichlorohydrin was added dropwise, the temperature of the reaction solution was raised to 40° C., and the reaction was carried out for two hours. After the reaction solution is cooled to room temperature, it is washed repeatedly with saturated sodium bicarbonate solution and deionized water until it becomes neutral, and dichloroethane is distilled off to obtain hydroxyl-terminated polyepichlorohydrin (PECH). Dissolve the self-made PECH in an appropriate amount of toluene, heat up to 90°C and add a certain amount of analytically pure NaOH. After reacting for four hours, add HCl aqueous solution to neutralize the remaining NaOH, and wash repeatedly with deionized water until the solution is neutral. properties, after distilling the toluene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com