Tube sheet component and bottom head component circumferential weld local heat treatment technology

A technology of local heat treatment and girth weld, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of different temperature control, large thickness, complex structure, etc., to achieve the effect of eliminating residual stress

Pending Publication Date: 2018-02-23

HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

View PDF13 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In order to overcome the above-mentioned problems, the present inventor has carried out intensive research and designed a local heat treatment process for the girth weld of the tube-sheet assembly and the lower head assembly. Then air cooling, not only solves the temperature control problems of the thicker thickness, complex structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

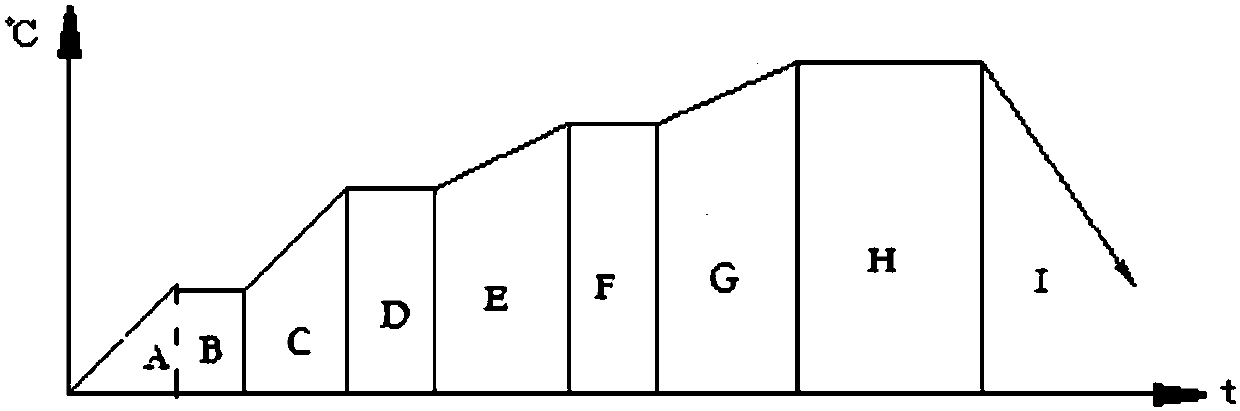

The invention relates to a tube sheet component and bottom head component circumferential weld local heat treatment technology. According to the technology, a stepped heating mode is adopted for conducting heating treatment on weld, and the problems that the tube sheet component and bottom head component circumferential weld in a steam generator is large in thickness and complex in structure, andtemperature control is difficult due to the fact that all parts are made of different materials are solved.

Description

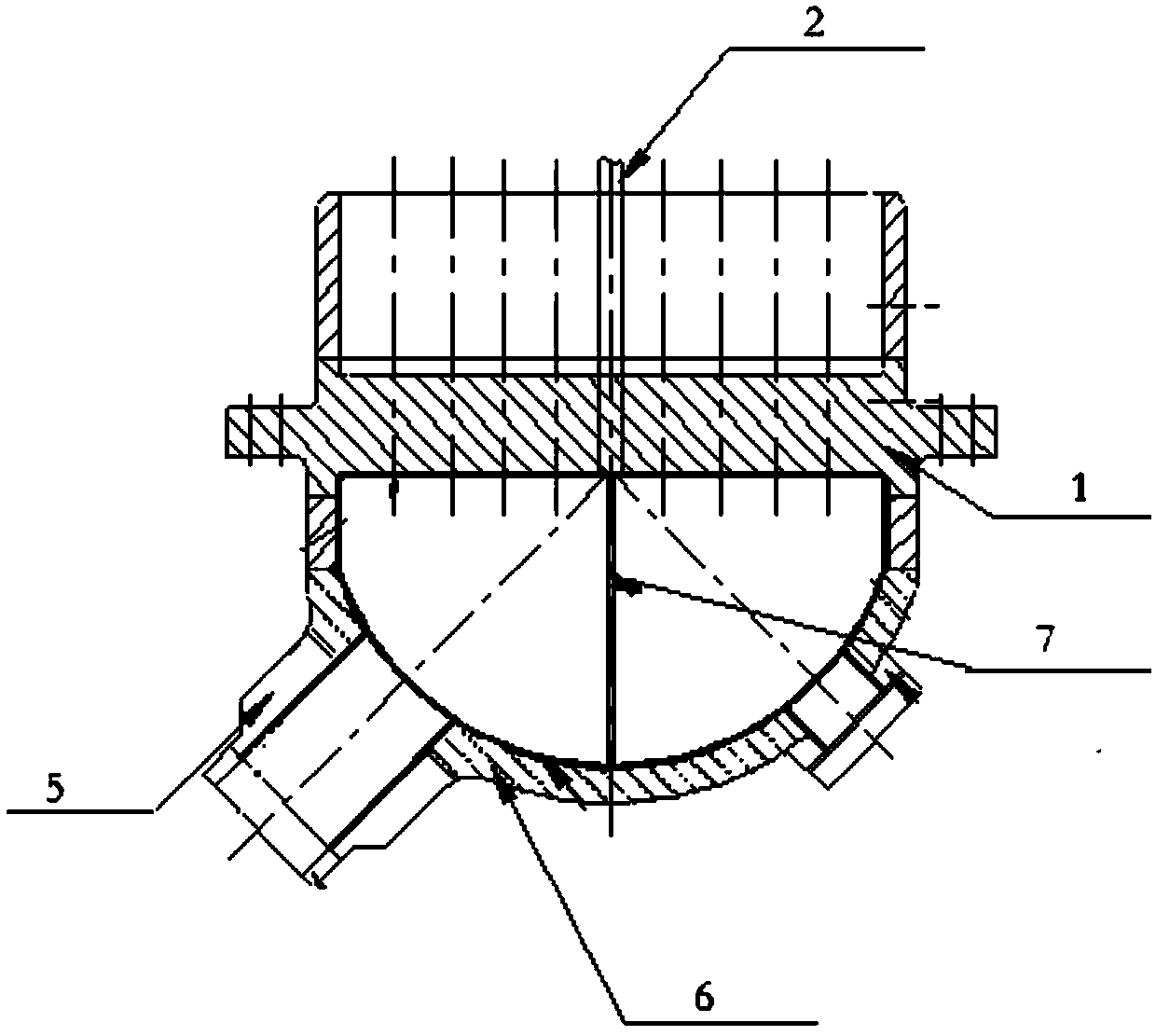

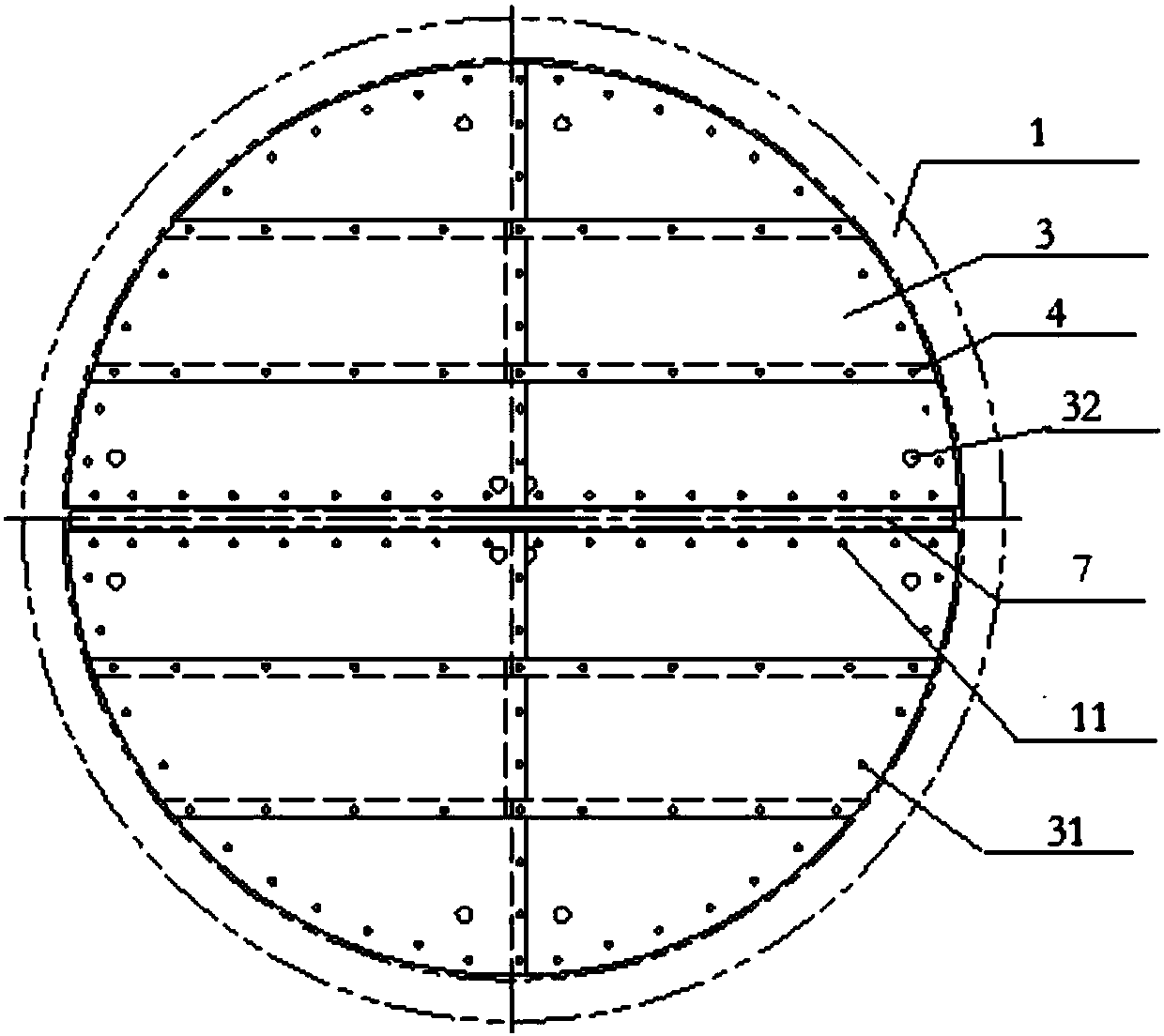

technical field [0001] The invention relates to a welding seam heat treatment process, in particular to a local heat treatment process for the circumferential weld seam of a steam generator tube plate assembly and a lower head assembly. Background technique [0002] At present, most of the steam generators manufactured at home and abroad are composed of a tube-sheet assembly (or called a lower cylinder assembly), a head assembly and a tube bundle assembly. The girth weld between the tube sheet assembly and the lower head assembly is used as the general assembly weld, and the safety end of the primary side connection pipe and the U-shaped heat exchange tube have also been assembled and welded. The welding of the steam generator tube plate and the lower head is an important process of the final assembly of the whole product. At this time, tens of thousands of heat exchange tubes are installed on the tube plate and the welding of the tube ends is completed. The center of the tu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21D9/50

CPCC21D9/50C21D9/505

Inventor 杜宁谢彦武王莉杜玉华邹迪静伦新杰

Owner HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com