Auxiliary bracket for strapping beam bars

A technology of auxiliary support and steel support, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of affecting binding efficiency, wasting time, and poor integrity of beams and reinforcements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

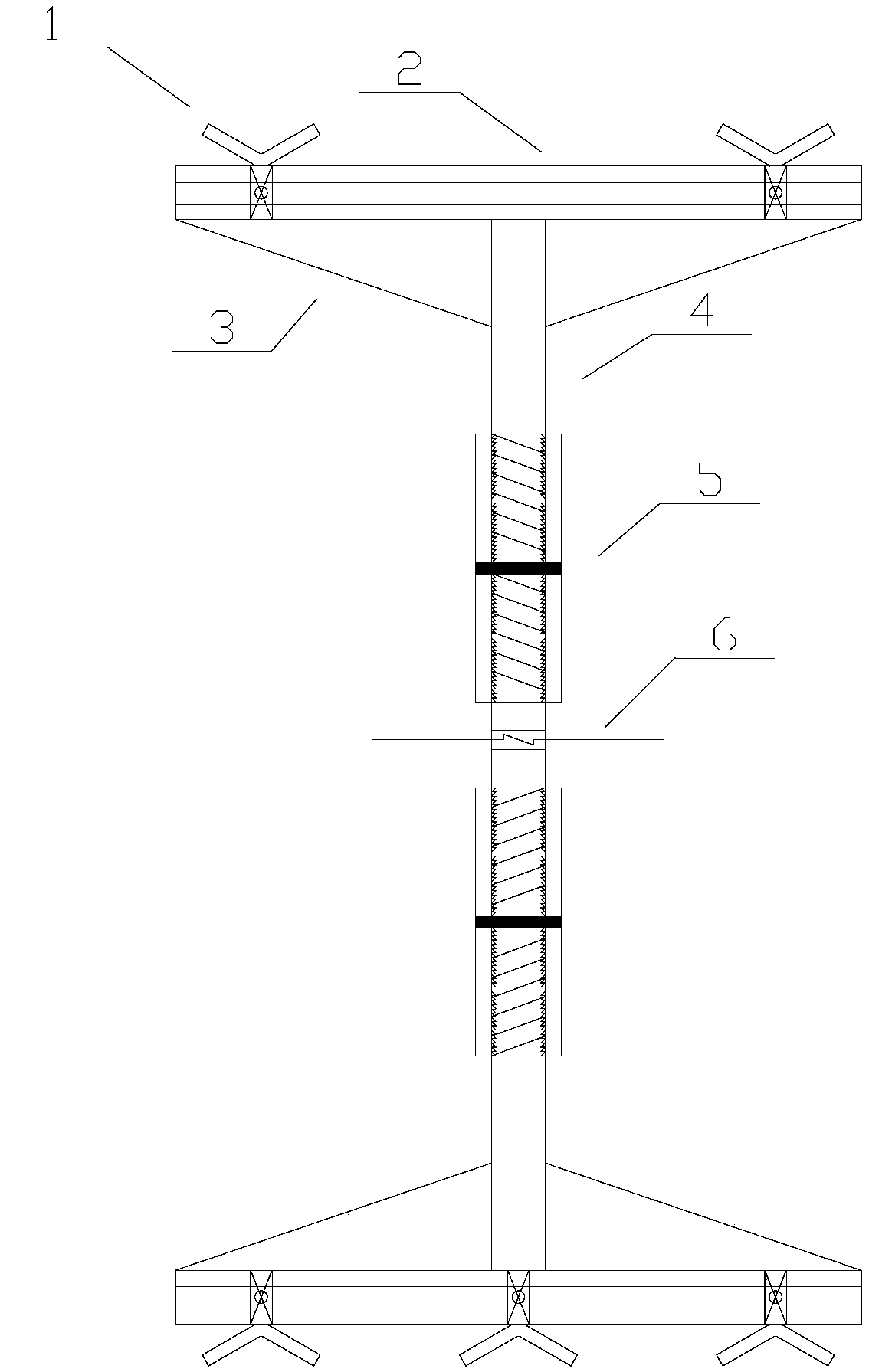

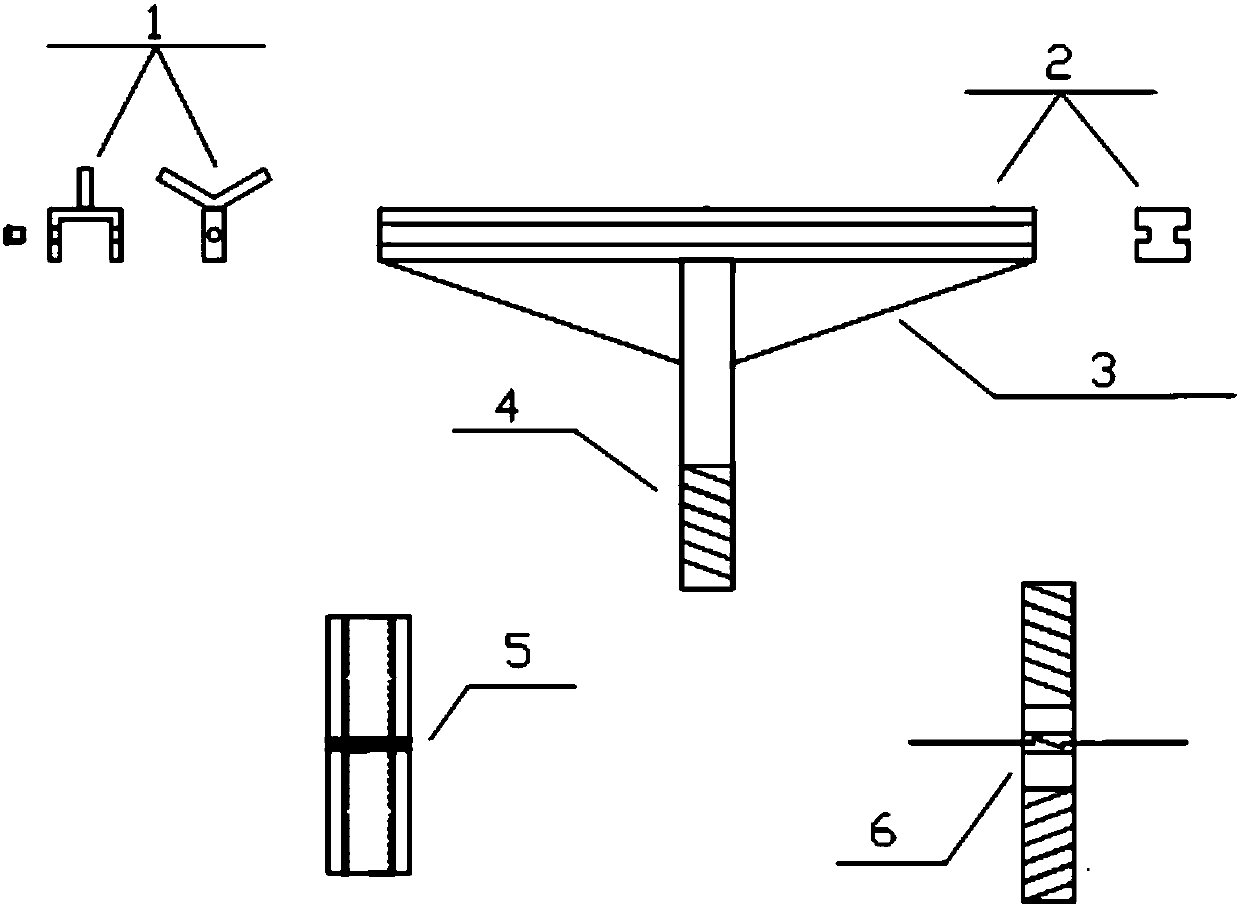

[0017] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] like Figure 1-2 As shown, the present embodiment discloses an auxiliary support for binding beams and bars, which includes the following parts:

[0019] Movable steel bar bracket 1: It consists of upper and lower parts. The upper part is unfolded at a certain angle to fix the steel bar. The lower part matches the groove of the horizontal support. There are screw holes on the side. support.

[0020] Horizontal support with groove 2: square steel bar with groove, the depth of the groove is consistent with the screw, to ensure the fixing of the movable bracket.

[0021] Supporting triangular plate 3: The role of the triangular plate is to reinforce and reinforce the stability of the entire system.

[0022] Pole 4: The main function is to support and transmit force. One end is welded with the horizontal support to ensure stability, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com