Eccentric-wear-prevention steel ball centralizer

A centralizer and anti-eccentric wear technology, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of difficult to pull the sucker rod, reduce the oil output efficiency, and the fixation degree of the sucker rod is not high, so as to prevent wear The effect of breaking, improving the degree of docking and fixing, and improving the oil output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

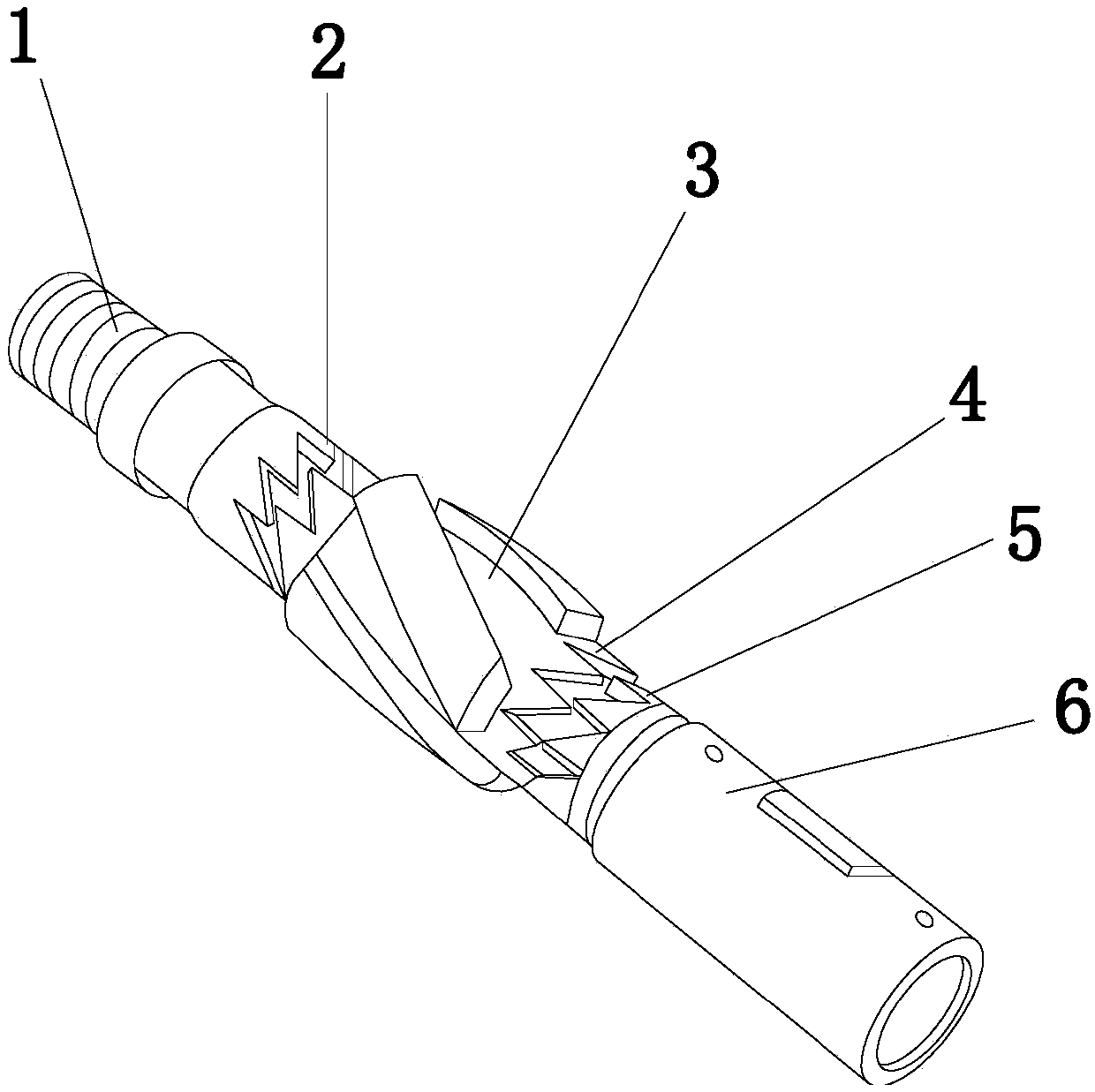

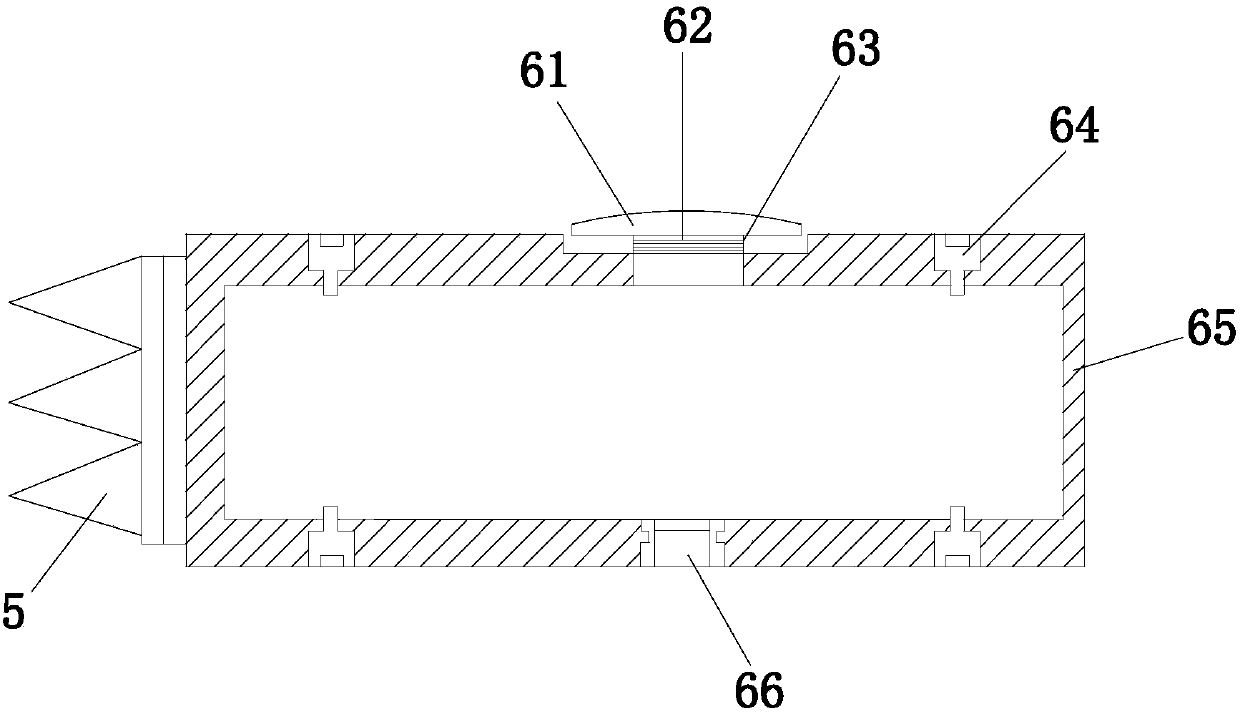

[0020] see Figure 1-Figure 2 , the present invention provides an anti-eccentric wear steel ball centralizer, the structure of which includes a lower threaded joint head 1, a lower threaded joint head centralizer sleeve 2, a pumping aid piston 3, a pumping aid piston centralizer gear sleeve 4, and an upper joint head centralizer sleeve 5 1. Connecting to the first 6, the upper and lower ends of the pumping aid piston 3 are provided with a pumping aid piston centralizing gear sleeve 4, and the plug centralizing gear sleeve 4 is fastened and fixed on the pumping aiding piston 3, and the pumping aiding piston 3 The left and right sides are respectively provided with a lower threaded joint 1 and an upper joint 6, and the lower threaded joint 1 and the upper joint 6 are respectively provided with a lower threaded joint centralizing sleeve 2 and an upper jointing joint centralizing sleeve 5, The lower threaded connecting head 1 cooperates with the pumping aid piston centralizing gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com